What is an Air Hydraulic Pump and How Does It Work?

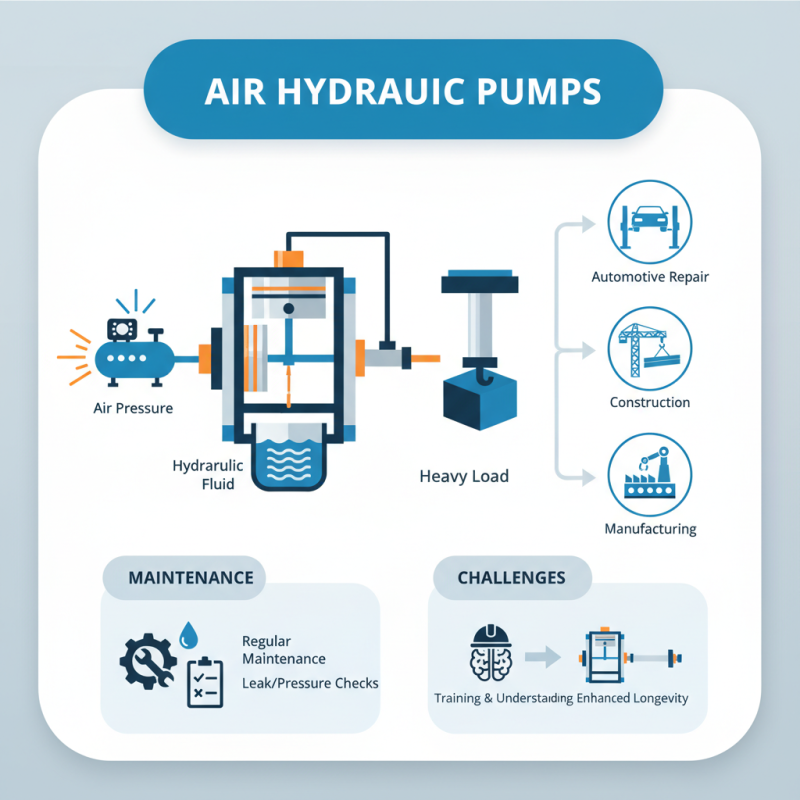

Air hydraulic pumps are vital tools in various industries. They combine air pressure and hydraulic fluid power. This synergy allows for efficient lifting and movement of heavy loads. According to a report by the International Hydraulic Association, the market for hydraulic systems is expected to grow significantly. The demand for air hydraulic pumps is expected to rise with this market trend.

These pumps function by converting compressed air into hydraulic pressure. This process is essential for applications such as construction, automotive repair, and manufacturing. In settings where weight and space are critical, air hydraulic pumps provide solutions that traditional pumps cannot. They are often used to lift vehicles or heavy machinery, maximizing efficiency.

Yet, there are challenges with air hydraulic pumps. They require regular maintenance to function optimally. Users must be aware of potential leaks and pressure drops that can affect performance. Many forget this aspect. Proper training and understanding of these tools can mitigate such issues, enhancing their longevity. This awareness is crucial for maximizing investment in air hydraulic pumps.

What is an Air Hydraulic Pump?

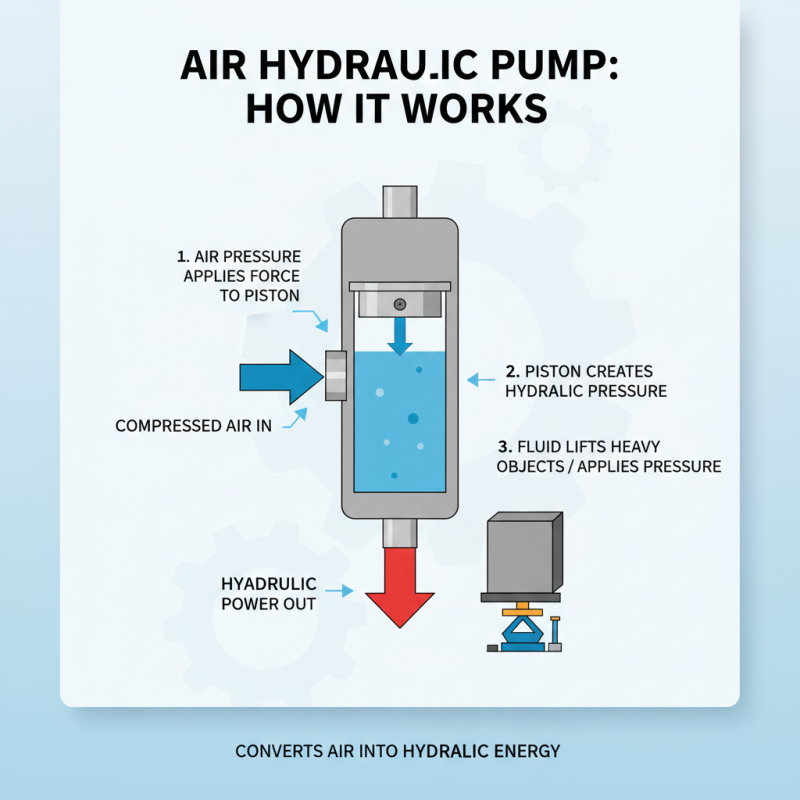

An air hydraulic pump is a powerful tool that combines air pressure and hydraulic fluid to produce significant force. It operates by converting compressed air into hydraulic energy, which can then be used to lift heavy objects or apply pressure in various applications. The pump features a cylinder that houses a piston, which moves in response to air pressure, creating hydraulic pressure on the fluid. Understanding how this mechanism works is essential for effective and safe use.

In practice, users must ensure the air supply is consistent. Any fluctuation can lead to inconsistent performance. The hydraulic fluid is equally important; it must be clean to avoid damage to the system. These pumps can be noisy, and improper maintenance can lead to leaks. Operators need to regularly check for worn seals and other wear indicators. Safety procedures should never be overlooked, as hydraulic pressure can be dangerous.

Understanding the limitations of an air hydraulic pump is crucial. Weight limits exist for a reason, and exceeding them can cause failures. Users might feel tempted to push the equipment further, but taking risks can lead to accidents or equipment damage. Inspections and proper handling can boost efficiency and longevity, although they require diligence and time. Being aware of the pump's operational quirks and maintenance needs can prevent unforeseen issues down the line.

Basic Components of an Air Hydraulic Pump

An air hydraulic pump combines air and hydraulic power to operate machinery efficiently. This system consists of several key components that work harmoniously. The primary parts include the air motor, hydraulic cylinder, and a control valve. Each element plays a crucial role in delivering necessary pressure to lift or move heavy loads.

The air motor provides the initial force. It converts compressed air into mechanical energy. This energy drives the hydraulic pump, which generates high pressure. The hydraulic cylinder then utilizes this pressure to perform work, like lifting or pushing objects. A control valve regulates fluid flow and pressure within the system. Ensuring these components are well-maintained is vital for optimal performance.

Tips: Always check the air supply before use. Properly lubricated connections prevent malfunctions. Remember, regular inspections can extend the pump's lifespan. A well-functioning air hydraulic pump can boost productivity, but neglect might lead to inefficiencies. According to the International Fluid Power Society, well-maintained hydraulic systems can achieve up to 90% efficiency. However, improper usage can reduce performance significantly. Observing the balance between air and hydraulic power is essential for achieving desired outcomes.

How Does an Air Hydraulic Pump Work?

An air hydraulic pump operates by converting air pressure into hydraulic energy. This process begins when compressed air enters the pump, typically through a fitting located on the top. The air pressure pushes a piston, which then forces hydraulic fluid through a connected line. According to industry reports, these pumps can generate pressures ranging from 10 to 300 psi. Such efficiency makes them a preferred choice in many industrial applications.

The working mechanism can sometimes lead to inconsistencies. Factors like air quality and temperature can affect performance. Additionally, the pump’s hydraulic fluid might degrade over time, creating potential risks. In some cases, air leaks can cause a drop in pressure, resulting in inefficient operation. Reports suggest that maintenance practices can enhance lifespan, but they are often overlooked.

Another aspect worth considering is the versatility of these pumps. They can operate various tools and machinery, making them valuable in different sectors. However, their complexity may create challenges for inexperienced users. Understanding the specific requirements and limitations is crucial for optimal performance. Adopting a cautious approach can help avoid potential pitfalls.

Applications of Air Hydraulic Pumps

Air hydraulic pumps are essential in various industries. They combine compressed air with hydraulic fluid to generate high-pressure power. This mechanism finds extensive applications across sectors like manufacturing, construction, and automotive.

In the manufacturing sector, air hydraulic pumps are crucial for operating molds and presses. According to a report by MarketsandMarkets, the global hydraulic pump market is projected to reach $24.3 billion by 2026. This growth stems from increased automation. In construction, these pumps power heavy machinery, helping lift equipment and materials efficiently.

Tips: Regular maintenance of air hydraulic pumps ensures optimal performance. Check hydraulic fluid levels frequently. Pay attention to any unusual noises that may indicate issues.

In automotive service, air hydraulic pumps assist in lifting vehicles for repairs. They provide the necessary force to elevate heavy parts. Yet, improper use can lead to safety risks. Training operators is vital for safe operations. Miscommunication often leads to accidents. It’s essential to establish clear protocols for pump usage.

What is an Air Hydraulic Pump and How Does It Work? - Applications of Air Hydraulic Pumps

| Application | Description | Working Principle | Advantages |

|---|---|---|---|

| Automotive Repair | Used for lifting heavy car components such as engines and transmissions. | Converts compressed air into hydraulic energy to lift heavy objects. | Efficient lifting with minimal manual effort. |

| Construction | Utilized for operating hydraulic machinery and tools on job sites. | Uses air pressure to generate hydraulic flow to power equipment. | High power-to-weight ratio, improves portability. |

| Manufacturing | For pressing, shaping, or moving components in assembly lines. | Employs air pressure to drive hydraulic pistons for precise motions. | Rapid operation enhances productivity. |

| Aerospace | Used for maintenance and assembly of aircraft components. | Transfers air pressure to hydraulic systems for fine control. | Reliable and precise performance crucial for safety. |

| Marine | Used in shipbuilding and maintenance of marine equipment. | Utilizes air to drive hydraulic systems for lifting and moving heavy loads. | Durability and efficiency in challenging environments. |

Advantages and Limitations of Air Hydraulic Pumps

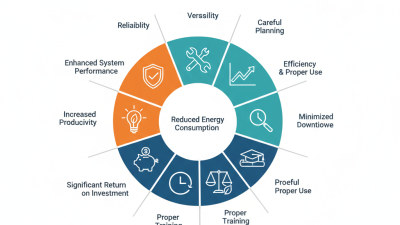

Air hydraulic pumps are renowned for their efficiency in industrial applications. They harness compressed air to generate substantial hydraulic pressure. Reports indicate that these pumps can reach output pressures of up to 1300 psi. This advantage makes them ideal for heavy lifting tasks. They are certainly valuable in workshops and construction sites.

However, there are limitations. Air hydraulic pumps require a consistent air source. If air pressure drops, performance suffers. Portability is another issue. While some models are equipped with wheels, their overall weight can be cumbersome. Many operators find maneuvering them difficult in tight spaces. A recent study found that nearly 25% of complaints stemmed from mobility issues.

Despite these drawbacks, air hydraulic pumps remain popular. Their ability to handle heavy loads efficiently cannot be overstated. Yet, constant maintenance is essential. Regular checks can prevent failure during critical operations. This reality prompts users to weigh the benefits against operational challenges carefully. Air hydraulic pumps can be both beneficial and problematic, requiring a thoughtful approach.

Related Posts

-

How to Optimize Air Hydraulic Pump Performance for Maximum Efficiency

-

How to Choose the Right Hydraulic Pump for Your Project?

-

The Ultimate Guide to the Best 5 Air Hydraulic Pumps for Efficient Performance in 2023

-

How to Choose the Right Gas Powered Hydraulic Pump for Your Needs

-

Top 10 Benefits of Using Hydraulic Power Units for Your Projects?

-

Electric Hydraulic Pump Tips for Efficiency and Maintenance?

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us