What is an Air Hydraulic Pump and How Does it Work for Your Needs

Air hydraulic pumps are essential tools in various industries, providing efficient and reliable performance in lifting and transferring heavy loads. According to a report by the International Hydraulic Association, the air hydraulic pump market is projected to grow at a CAGR of 5.6% from 2021 to 2026, driven by increasing demand in construction and manufacturing sectors. These pumps utilize compressed air to produce hydraulic force, making them invaluable for tasks requiring high lifting capabilities without the need for electrical power.

Industry expert Dr. John Stevens, a renowned figure in hydraulic technology, emphasizes the importance of air hydraulic pumps by stating, “The versatility of air hydraulic pumps allows for a safer and more efficient working environment in high-demand industries.” This reflects a growing trend as more companies recognize the benefits of adopting such technologies to streamline operations and enhance productivity. As they continue to integrate air hydraulic pumps into their workflows, organizations can achieve not only improved performance but also significant cost savings, highlighting their pivotal role in modern industrial applications.

What Is an Air Hydraulic Pump?

An air hydraulic pump is a device that combines pneumatic and hydraulic technology to convert air pressure into hydraulic force. This innovative equipment is often used in various industrial applications where high force and precise control are needed. Essentially, the pump utilizes compressed air to drive a piston that generates hydraulic pressure, which can then be used to operate hydraulic tools, lift heavy loads, or perform complex mechanical tasks.

One of the key advantages of using an air hydraulic pump is its efficiency in power conversion. It allows for rapid generation of force with minimal effort, making it ideal for tasks that require lifting, pushing, or pulling heavy objects. Moreover, air hydraulic pumps are versatile and can be powered by a standard air compressor, giving them an edge in environments where electricity may not be readily available or practical.

Tips: When using an air hydraulic pump, always ensure that the air pressure is within the recommended range for optimal performance and safety. Regular maintenance, such as checking for leaks and lubrication, can extend the lifespan of the pump and ensure it operates reliably. Additionally, take the time to familiarize yourself with the specific applications of your pump to maximize its effectiveness in your projects.

Air Hydraulic Pump Efficiency by Pressure Level

Key Components of Air Hydraulic Pumps

Air hydraulic pumps are vital tools used across various industries, including manufacturing, automotive, and construction, for lifting, pushing, or pulling heavy loads. Understanding the key components of these pumps is essential for maximizing their efficiency and performance. An air hydraulic pump primarily consists of three main components: the air motor, the hydraulic cylinder, and the control valves.

The air motor serves as the pump's powerhouse, converting compressed air energy into mechanical energy to drive the hydraulic system. According to a report by the International Journal of Industrial Engineering, air motors can achieve power-to-weight ratios of 3:1 compared to electric motors, making them a favorable choice for mobile applications. The hydraulic cylinder then steps up the force generated by the air motor, using hydraulic fluid to amplify the power for tasks like lifting and clamping. The combination of these elements ensures smooth and effective operations, which can be crucial in time-sensitive manufacturing processes.

Control valves are another critical component, allowing operators to manage the flow of hydraulic fluid through the system. This control facilitates precise operation, enhancing safety and efficiency during use. The hydraulic system's reliability can significantly reduce operational downtimes, with studies indicating that proper maintenance and understanding of these components can increase the lifespan of the equipment by up to 40%. By familiarizing themselves with these key components, users can better utilize air hydraulic pumps to meet their specific needs and improve their overall operational effectiveness.

How Air Hydraulic Pumps Operate

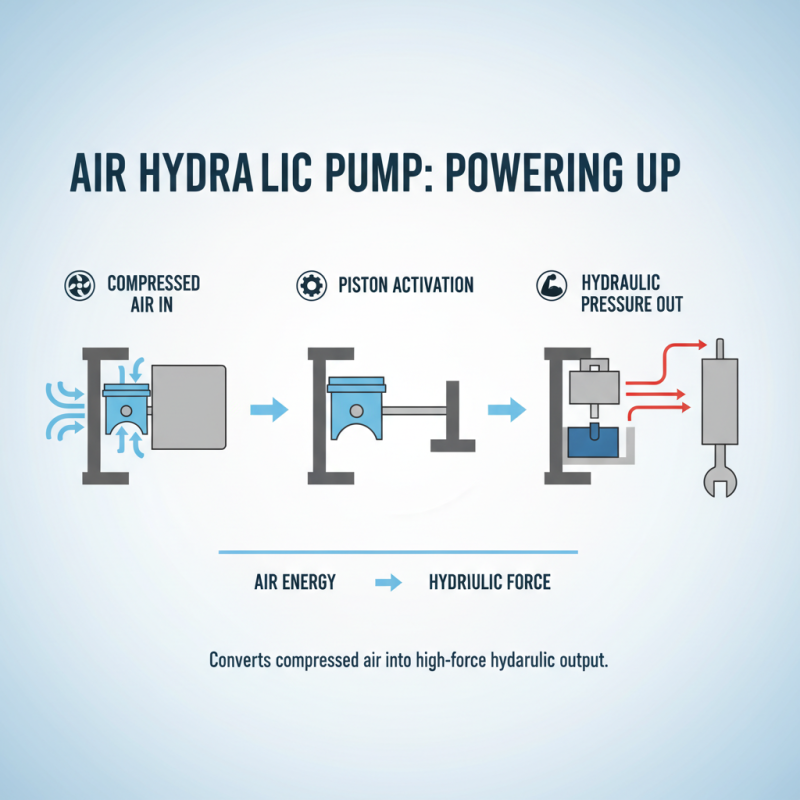

Air hydraulic pumps are powerful devices that utilize compressed air to generate hydraulic pressure, allowing them to perform a wide range of tasks efficiently. The operation of these pumps begins when compressed air is introduced into the pump’s air cylinder. This air pressure activates a piston that moves within the cylinder, consequently creating a hydraulic fluid pressure in the connected hydraulic system. The sequence of actions transforms the energy from compressible air into a high-force output that can drive various hydraulic tools and machinery.

Once the air hydraulic pump is activated, it controls the movement of the hydraulic fluid, which is typically oil, through hoses to cylinders that perform work. The pump can be adjusted to regulate the pressure and output flow rate, enabling it to tackle different applications, from lifting heavy loads to powering specialized machinery. By employing the principle of Pascal's law, where pressure applied in one part of a confined fluid is transmitted equally throughout, air hydraulic pumps can provide substantial force in a compact design, making them ideal for industrial and construction needs.

Applications of Air Hydraulic Pumps in Various Industries

Air hydraulic pumps are versatile tools utilized across various industries due to their unique ability to convert air pressure into hydraulic force. In the construction industry, these pumps are essential for lifting heavy materials and equipment, enabling efficient operations on job sites. Their lightweight design and portability allow workers to maneuver them easily, making tasks such as lifting scaffolding or operating hydraulic jacks more manageable and safe.

In the automotive sector, air hydraulic pumps play a crucial role in repair and maintenance activities. They are used for powering hydraulic lifts and hoists, which assist in servicing vehicles by elevating them for easy access. This not only enhances productivity but also ensures a safer environment for technicians. Additionally, industries like manufacturing and aviation employ air hydraulic pumps in assembly lines and for testing equipment, highlighting their importance in streamlining processes and improving operational efficiency. The adaptability of air hydraulic pumps makes them indispensable across various applications, enhancing productivity and safety in multiple settings.

Maintenance Tips for Optimal Performance of Air Hydraulic Pumps

Air hydraulic pumps are essential tools that combine air pressure and hydraulic force to power various machinery and tasks. To ensure these pumps function optimally, regular maintenance is crucial. One of the primary maintenance tips is to keep the air filters clean and check them frequently. Dirty filters can lead to reduced efficiency and potential damage to the pump over time. Moreover, it’s important to inspect the hydraulic fluid levels regularly, as low fluid can cause overheating and decreased performance.

Additionally, lubrication of moving parts is vital for smooth operation. Regularly applying the appropriate lubricant reduces friction and wear, extending the lifespan of the pump. Routine inspections of the hoses and connections for leaks or signs of wear can prevent operational downtime and costly repairs. By adhering to these maintenance practices, users can ensure that their air hydraulic pumps remain reliable and efficient, catering to their specific needs effectively.

What is an Air Hydraulic Pump and How Does it Work for Your Needs - Maintenance Tips for Optimal Performance of Air Hydraulic Pumps

| Aspect | Details |

|---|---|

| Definition | An air hydraulic pump is a device that uses compressed air to generate hydraulic pressure, allowing for powerful lifting and moving of heavy loads. |

| Working Principle | Compressed air is directed into a cylinder, which pushes a piston that generates hydraulic fluid flow and pressure, allowing for actuation of hydraulic systems. |

| Applications | Used in automotive repair, lifting heavy machinery, and industrial equipment maintenance. |

| Key Benefits | Efficiency in lifting, ease of operation, and compact design that saves space. |

| Maintenance Tips | Regularly check for leaks, ensure clean air supply, lubricate moving parts, and inspect hoses and fittings for wear. |

| Common Issues | Loss of pressure, noise during operation, and slow pump response. |

| Safety Precautions | Always wear protective equipment, ensure the pump is maintained, and operate within the specified limits. |

Related Posts

-

How to Optimize Air Hydraulic Pump Performance for Maximum Efficiency

-

How to Optimize the Performance of Your Hydraulic Pump Motor

-

The Ultimate Guide to the Best 5 Air Hydraulic Pumps for Efficient Performance in 2023

-

Unveiling Trends in Electric Hydraulic Pump Demand at China's 138th Canton Fair 2025: Market Insights and Growth Forecasts

-

Unlocking Efficiency with Hydraulic Power Packs Understanding Their Impact on Industrial Applications

-

The Ultimate Guide to Understanding Hydraulic Pumps and Motors for Efficient Machinery Performance

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us