The Best 10 Advantages of Pneumatic Hydraulic Systems for Your Business

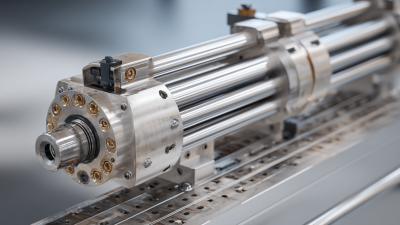

In today's competitive business landscape, efficiency and precision are paramount, particularly for industries reliant on complex machinery. One innovative solution that has gained significant traction is the pneumatic hydraulic system. These systems, which combine the best attributes of pneumatic and hydraulic technologies, offer a myriad of advantages that can revolutionize business operations. From enhanced power-to-weight ratios to the ability to operate in challenging environments, pneumatic hydraulic systems have become indispensable assets for many enterprises.

The integration of pneumatic hydraulic technology can greatly optimize productivity and reduce operational costs. For instance, these systems facilitate quick response times and robust force generation, making them ideal for tasks requiring high precision and reliability. As businesses continue to seek solutions that not only improve efficiency but also contribute to sustainability, pneumatic hydraulic systems provide a compelling option, often leading to increased throughput and reduced energy consumption. In this article, we will explore the top 10 advantages that pneumatic hydraulic systems offer, demonstrating why they are a smart choice for businesses aiming to enhance their operational capabilities and secure a competitive edge in their respective markets.

Advantages of Enhanced Efficiency in Pneumatic Hydraulic Systems

Pneumatic hydraulic systems have gained significant traction in various industries due to their enhanced efficiency, which stands as a core advantage. These systems combine the principles of both pneumatics and hydraulics, resulting in speed and power that can greatly improve production processes. By utilizing compressed air and hydraulic fluids, businesses can achieve quicker response times and maintain consistent pressure, leading to less downtime and more streamlined operations.

Moreover, the efficiency of pneumatic hydraulic systems minimizes energy consumption and operational costs, which is crucial for enhancing overall productivity. With reduced mechanical wear and tear compared to traditional systems, maintenance requirements are also lowered, allowing businesses to allocate resources more effectively. The ability to easily control force and speed further increases versatility across applications, making these systems an ideal choice for industries that prioritize both precision and performance. By investing in pneumatic hydraulic systems, businesses can not only boost efficiency but also stay competitive in an ever-evolving market.

Cost-Effectiveness: Saving Money with Pneumatic Hydraulic Solutions

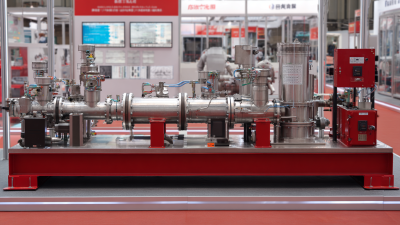

Pneumatic hydraulic systems have become increasingly popular in various industries, primarily due to their cost-effectiveness. Companies are continually seeking innovative solutions that not only streamline operations but also help in minimizing expenditures. By adopting pneumatic hydraulic systems, businesses can realize significant savings in energy costs and maintenance. Reports indicate that these systems can reduce operational costs by up to 30% compared to traditional hydraulic solutions, making them an attractive option for industries ranging from mining to manufacturing.

Moreover, the efficient design of pneumatic hydraulic systems enhances overall productivity. For instance, a set of hydraulically operated pinch valves installed at a major gold mine in North Africa has successfully operated for seven years without service interruptions, demonstrating both reliability and durability. Such long-term performance minimizes downtime and associated costs, allowing businesses to redirect their resources more effectively.

**Tips:** To maximize cost savings with pneumatic hydraulic systems, ensure regular maintenance checks and invest in quality components to increase the system's lifespan. Additionally, consider training your staff on optimal usage practices, as proper operation can further reduce wear and maintenance costs. Embracing these systems not only drives down expenses but also contributes to a more sustainable operational model.

The Cost-Effectiveness of Pneumatic Hydraulic Systems

Improved Safety Features Over Traditional Systems

Pneumatic hydraulic systems have emerged as a game-changer for businesses, particularly due to their enhanced safety features compared to traditional systems. One of the primary advantages is the reduction in the risk of fluid leaks. Unlike conventional hydraulic systems that rely heavily on liquid fluids, pneumatic systems utilize compressed air, minimizing the chances of spills that can cause workplace accidents. This shift not only protects the environment but also ensures a safer working environment for employees.

Additionally, pneumatic hydraulic systems are often equipped with fail-safe mechanisms. These systems can automatically shut down in case of a malfunction, preventing potential accidents before they occur. The integration of advanced sensors also allows for real-time monitoring, giving operators immediate feedback.

Tips:

- Always conduct routine maintenance checks on pneumatic systems to detect any possible issues early.

- Training employees on the proper use and safety protocols of these systems can significantly reduce the risk of accidents.

- Lastly, consider investing in additional protective equipment to enhance safety measures further, ensuring a secure workplace for everyone.

Versatility in Applications Across Various Industries

Pneumatic hydraulic systems are increasingly becoming the backbone of various industries due to their remarkable versatility in applications. These systems combine the advantages of both pneumatic and hydraulic power, allowing businesses to use them in diverse environments. From manufacturing and automotive to food processing and construction, pneumatic hydraulic systems adapt seamlessly to the specific needs of different operations. Their ability to handle heavy loads while maintaining precise control makes them ideal for tasks ranging from lifting and positioning to automated assembly and packaging.

Moreover, the flexibility of pneumatic hydraulic systems allows for easy integration into existing workflows. They can be tailored to fit unique specifications, making it possible for companies to optimize their production processes while reducing the risk of downtime. The energy efficiency and compact design of these systems further enhance their versatility, allowing businesses to maximize space and resources. As a result, industries looking to improve productivity and reliability can significantly benefit from implementing pneumatic hydraulic systems into their operations.

The Best 10 Advantages of Pneumatic Hydraulic Systems for Your Business

| Advantage | Description | Applications | Industry |

|---|---|---|---|

| High Power-to-Weight Ratio | Pneumatic hydraulic systems provide significant power with minimal weight, enhancing equipment efficiency. | Lifting and moving heavy loads | Manufacturing, Construction |

| Versatility | Can be used in various applications, from automotive to aerospace. | Machine operation, Automation | Automotive, Aerospace |

| Energy Efficiency | Lower energy consumption compared to traditional systems, reducing operational costs. | Power tools, Compressors | Manufacturing, Construction |

| Safety | Inherently safe due to lower pressure requirements and reduced risk of dangerous leaks. | Material handling, Production lines | Manufacturing, Warehousing |

| Cost-Effectiveness | Lower initial and maintenance costs compared to electric hydraulic systems. | Construction equipment, Industrial machinery | Construction, Manufacturing |

| Quick Response Time | Faster actuation means quicker workflow and reduced cycle time. | Automation, Robotics | Automotive, Manufacturing |

| Simplified Maintenance | Easier to service and maintain due to fewer moving parts and fluid systems. | Heavy machinery, Production units | Construction, Manufacturing |

| Reduced Noise Levels | Operates more quietly than electric systems, improving workplace conditions. | Construction sites, Workshops | Construction, Manufacturing |

| Environmentally Friendly | Uses air and water, reducing pollution compared to hydraulic oils. | Material handling, Transportation | Warehousing, Logistics |

Easy Maintenance and Reduced Downtime for Operations

Pneumatic hydraulic systems offer significant advantages for businesses by ensuring easy maintenance and reduced downtime, which are critical for operational efficiency. With these systems, companies can experience substantial improvements in equipment reliability. According to a recent industry report, businesses implementing predictive maintenance strategies can reduce unplanned downtime by up to 30%. This proactive approach not only enhances performance but also minimizes operational disruptions, allowing teams to focus on productivity rather than repairs.

Additionally, leveraging advanced software tools can further streamline maintenance processes. For instance, integrating data analytics helps in forecasting maintenance needs, ensuring that necessary adjustments are made before issues arise. Studies show that companies using integrated maintenance software report a 25% improvement in overall asset reliability. This aligns with the trend of evolving from reactive maintenance models to predictive success, as organizations recognize the value of anticipating issues before they impact operations.

**Tips:** Regularly review your maintenance schedules and incorporate data-driven decisions to optimize your pneumatic hydraulic systems. Consider investing in training for your team to familiarize them with new technologies, enhancing overall maintenance efficiency. Also, explore collaboration with technology providers to tailor predictive tools that fit your specific operational needs.

Related Posts

-

Essential Pneumatic Hydraulic Maintenance Checklist for Optimal Performance

-

Understanding Common Issues with Hydraulic Pumps and Motors in Industrial Applications

-

How to Optimize Pneumatic Hydraulic Systems for Enhanced Performance

-

Revolutionizing Hydraulic Systems Trends and Insights at the 138th China Import and Export Fair 2025

-

10 Essential Tips for Mastering Pneumatic and Hydraulic Systems

-

Top 10 Essential Hydraulic System Components for Optimal Performance

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us