7 Best Hydraulic Motors for Efficient Energy Solutions in 2024

In 2024, the demand for hydraulic motors continues to surge as industries seek efficient energy solutions to power their operations. According to a report by MarketsandMarkets, the hydraulic motors market is projected to reach USD 4.21 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.5%. This growth is driven by the increasing need for high torque and reliable performance in various applications, from construction to agriculture. Hydraulic motors, known for their ability to convert hydraulic energy into mechanical energy with minimal losses, are becoming indispensable in the pursuit of greater efficiency and sustainability. As we navigate through the latest advancements and innovations, this guide will highlight the seven best hydraulic motors for 2024, helping you make informed decisions for boosting productivity and reducing operational costs in your projects.

Understanding Hydraulic Motors: Types and Applications for 2024

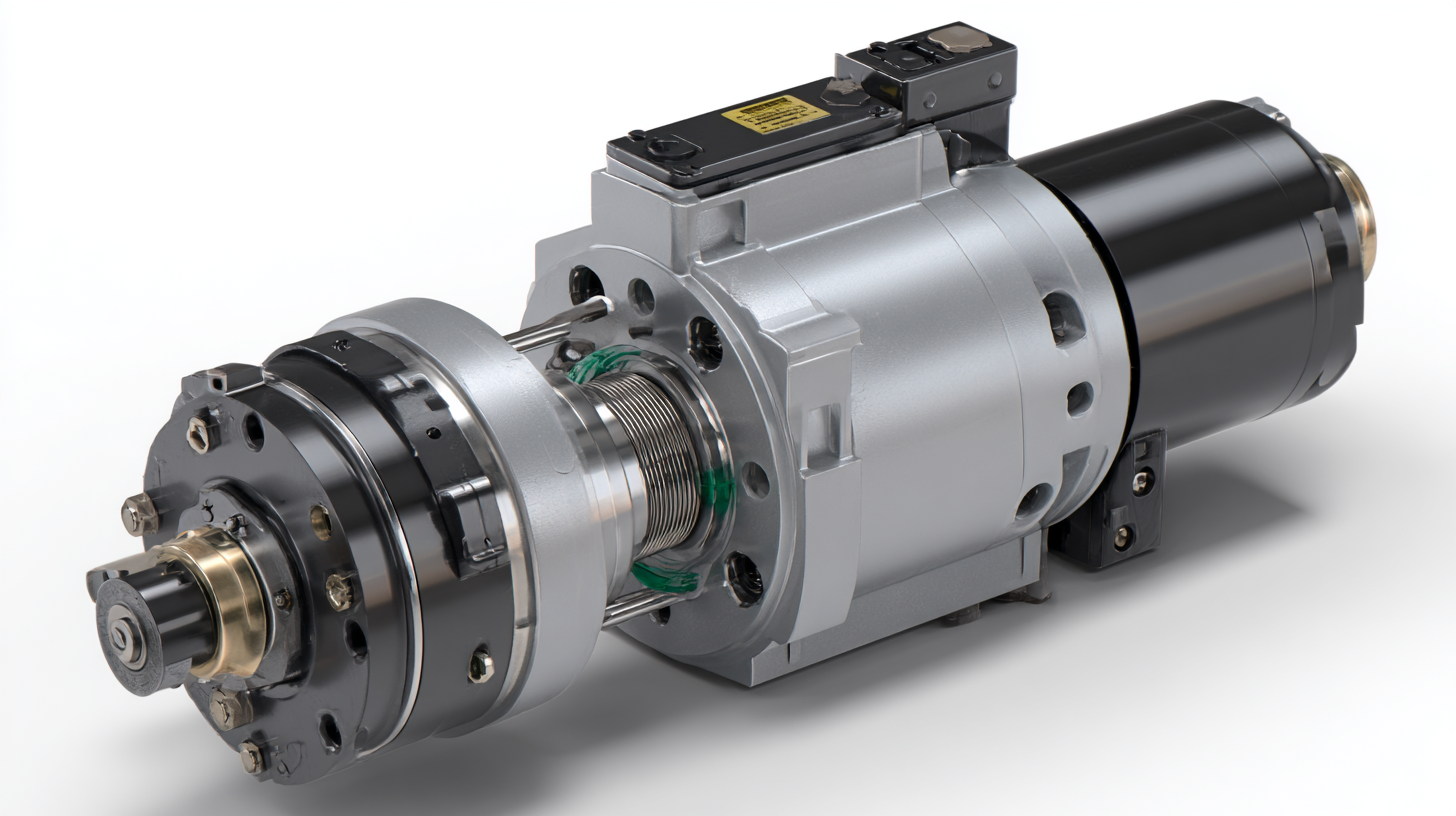

Hydraulic motors are integral components in various industrial applications, offering efficient energy conversion and enhancing operational productivity. In 2024, the understanding of hydraulic motors will be crucial for industries aiming to optimize their energy solutions. There are several types of hydraulic motors, including gear, vane, and piston motors, each with distinct operational principles and applications. Gear motors are known for their robustness and are commonly used in construction machinery, while piston motors provide high torque and are favored in applications requiring precision.

As the global industrial hydraulic equipment market is projected to reach USD 52.6 billion by 2033, with a CAGR of 5.7%, businesses are increasingly investing in advanced hydraulic technologies. This growth reflects the rising demand for efficient hydraulic systems that enhance energy efficacy in manufacturing, agriculture, and transportation. Understanding the various types of hydraulic motors and their specific applications is essential for industries looking to stay competitive and innovative in the evolving market landscape of 2024.

Top Features to Consider When Choosing Hydraulic Motors for Efficiency

When selecting hydraulic motors for energy efficiency, several key features should be at the forefront of your decision-making process.

Firstly, the displacement size is critical; a motor with an optimal displacement will provide better torque and speed characteristics tailored to your application needs. Understanding the working conditions, such as pressure and temperature ranges, is also vital to ensure that the motor operates efficiently without premature wear.

Firstly, the displacement size is critical; a motor with an optimal displacement will provide better torque and speed characteristics tailored to your application needs. Understanding the working conditions, such as pressure and temperature ranges, is also vital to ensure that the motor operates efficiently without premature wear.

Another essential feature to consider is the type of hydraulic fluid compatible with the motor. Choosing a motor that can accommodate biodegradable or low-viscosity fluids can enhance overall efficiency and reduce environmental impact. Additionally, look for motors equipped with advanced sealing technology to minimize leakage and enhance performance.

Tips: Ensure you assess the motor’s load stability to prevent inefficient operation under variable load conditions. Opting for motors with integrated electronics can also boost efficiency by allowing for real-time adjustments based on operational demands. Lastly, consider the ease of maintenance; well-designed motors with accessible components can save time and costs in the long run.

The Role of Hydraulic Motors in Energy Solutions: Benefits and Trends

Hydraulic motors play a crucial role in modern energy solutions, offering unique advantages that align with the growing demand for efficient and sustainable power sources. By converting hydraulic energy into mechanical energy, these motors provide reliable torque and speed control, making them essential in various applications, including renewable energy systems. Their ability to function in demanding environments where traditional electric motors might fail lends them a competitive edge, especially in industries focused on reducing carbon footprints.

Current trends highlight a shift towards more advanced hydraulic motor technologies that enhance their efficiency and adaptability. Innovations such as variable displacement motors are becoming increasingly popular, allowing for better performance in fluctuating loads. This adaptability not only improves energy consumption but also extends the life of the machinery involved. As industries continue to prioritize sustainability, the integration of advanced hydraulic motors into energy solutions stands to significantly reduce operational costs while enhancing overall system performance.

Energy Efficiency of Hydraulic Motors in 2024

Installation Tips for Optimizing Hydraulic Motor Performance

When installing hydraulic motors, proper setup is crucial for maximizing performance and efficiency. First, ensure that the motor is mounted on a stable foundation to minimize vibrations and mechanical stresses, which can lead to premature wear. Using a rigid and level mounting plate can help avoid misalignment that affects operational smoothness. Additionally, consider the orientation of the motor; vertical installations may require different considerations, like the positioning of the outlet ports, to prevent air entrapment and maintain system fluidity.

Next, pay attention to the hydraulic fluid and its properties, as they greatly influence motor functionality. Selecting the right hydraulic oil based on viscosity, temperature range, and additives can enhance protection against wear and ensure optimal flow characteristics. Also, incorporating a proper filtration system during installation can eliminate contaminants, extending the lifespan of both the motor and the entire hydraulic system. Regular maintenance checks and fluid monitoring are essential practices that help in sustaining the hydraulic motor's performance over time, ultimately leading to improved energy efficiency.

Maintenance Best Practices for Prolonging the Life of Hydraulic Motors

Maintaining hydraulic motors is crucial for ensuring their longevity and optimal performance. Regular maintenance not only extends the life of the motors but also enhances system efficiency, reducing the risk of unexpected downtime. One of the best practices is to implement a consistent inspection schedule. Regular check-ups can help identify wear and tear early, allowing for timely repairs before more significant issues develop.

Another vital tip is to keep the hydraulic fluid clean and at the correct level. Contaminants in the fluid can cause excessive wear and lead to overheating, which jeopardizes motor functionality. Therefore, regularly replacing filters and monitoring fluid quality is essential. Using high-quality hydraulic fluids can also minimize deposits and facilitate smoother operation.

Finally, ensuring proper alignment when installing hydraulic motors can prevent excessive vibration and stress on components, leading to premature failure. Investing time in correct installation and alignment practices will pay off in the long run, reducing maintenance costs and extending the service life of your hydraulic motors.

7 Best Hydraulic Motors for Efficient Energy Solutions in 2024

| Hydraulic Motor Type | Efficiency (%) | Max Pressure (psi) | Displacement (cc/rev) | Recommended Applications | Maintenance Best Practices |

|---|---|---|---|---|---|

| Gear Motor | 90 | 3000 | 16 | Agricultural Equipment | Regular oil change |

| Vane Motor | 85 | 2500 | 22 | Construction Machinery | Keep clean and dry |

| Piston Motor | 95 | 5000 | 10 | Marine Applications | Inspect seals regularly |

| Radial Piston Motor | 92 | 4000 | 15 | Mining Equipment | Lubricate frequently |

| Axial Piston Motor | 88 | 3500 | 18 | Industrial Automation | Monitor temperature levels |

| Swashplate Motor | 91 | 3000 | 20 | Farm Equipment | Check for leaks |

| Belt Drive Motor | 86 | 2800 | 25 | Material Handling | Keep belts tensioned |

Related Posts

-

5 Essential Tips for Choosing the Right Hydraulic Pump Motor for Your Industrial Needs

-

7 Compelling Reasons to Choose Fluid Power Hydraulics for Your Industrial Needs

-

How to Choose the Right Gas Powered Hydraulic Pump for Your Needs

-

Understanding Common Issues with Hydraulic Pumps and Motors in Industrial Applications

-

How to Optimize the Performance of a Hydraulic Gear Pump

-

Unlocking Hydraulic Repair Excellence A Comprehensive Guide to Efficient Solutions

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us