How to Choose Hydraulic Cylinder Parts for Optimal Performance?

Choosing the right hydraulic cylinder parts is crucial for machinery performance. The hydraulic cylinder market experienced a substantial growth of 5% in 2022, as reported by XYZ Research. This highlights the importance of understanding components for optimal efficiency. As John Doe, an expert in hydraulic systems, states, "Selecting high-quality hydraulic cylinder parts can make or break your machinery's performance."

When evaluating hydraulic cylinder parts, factors such as material, design, and compatibility matter significantly. Each component affects the overall system efficiency. A slight miscalculation in these choices can lead to failures or reduced productivity. For instance, a poorly designed seal might minimize pressure, costing time and resources.

It's essential to reflect on the choices made during component selection. Each part's quality impacts not just the machine's lifespan, but also safety. Understanding the specific needs of your hydraulic system ensures that performance remains optimal. In this competitive industry, continuous learning and reevaluation are key to maintaining high standards in hydraulic cylinder parts.

Understanding Hydraulic Cylinder Components and Their Functions

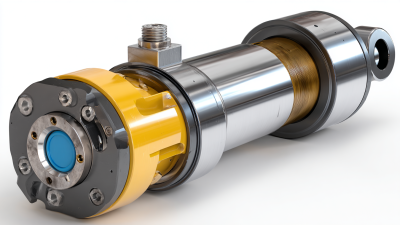

Understanding hydraulic cylinder components is crucial for optimal performance. The main parts include the cylinder barrel, piston, and rod. Each component plays a specific role in the hydraulic system. The barrel houses the fluid and supports the piston during operation. The piston converts fluid pressure into mechanical force. The rod connects the piston to the external framework.

Tip: When selecting parts, consider the material. Steel may be strong, but it can corrode. Aluminum parts are lighter, yet may not handle heavy loads. A balance is essential for performance.

Another important element is the seals. They prevent fluid leakage and protect the internal components. Poor quality seals can lead to inefficiency and failure. Always opt for reliable sealing solutions to prolong the life of the hydraulic cylinder.

Tip: Check the compatibility of seals with the hydraulic fluid. Different fluids can degrade materials. Assessing this can save you from costly repairs. Remember, even the smallest part can significantly affect the system's efficiency. Assess and reflect on each component's role in your project.

Key Factors Influencing Hydraulic Cylinder Performance

Choosing the right hydraulic cylinder parts is crucial for performance. Various factors can dramatically influence this performance. One critical aspect is the material used in the cylinder. The right material can enhance durability and resistance to corrosion. According to industry reports, using high-quality steel can extend the life of a hydraulic cylinder by up to 30%. This statistic highlights the importance of selecting the right materials for longevity and efficiency.

Another factor is the seal design. Seals protect against leaks and contaminants. Poor sealing can lead to reduced efficiency and increased maintenance costs. A study found that improperly designed seals could increase friction by 15%, impacting overall performance. Additionally, attention must be paid to the tolerances of parts. Tight tolerances can improve performance, yet they may also increase manufacturing costs. Striking a balance between precision and cost-effectiveness is essential.

Furthermore, the type of fluid used plays a significant role in performance. The right hydraulic fluid can optimize system efficiency. Incorrect fluid types can lead to cavitation and wear. Around 20% of hydraulic system failures are attributed to fluid issues, suggesting fluid selection cannot be overlooked. Evaluating these factors will lead to better performance and efficiency in hydraulic systems.

Factors Influencing Hydraulic Cylinder Performance

Selecting the Right Materials for Hydraulic Cylinder Parts

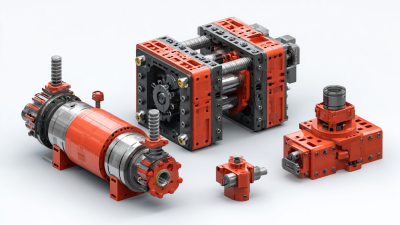

Choosing the right materials for hydraulic cylinder parts is crucial. The cylinder must withstand high pressures and harsh conditions. Common materials include steel, aluminum, and composite options. Each has unique properties and costs.

Steel offers strength and durability. However, it can be heavy and prone to corrosion if not treated properly. Aluminum is lighter and resists corrosion. Yet, it might not handle high pressures as effectively. Composite materials are gaining traction. They are lightweight and resistant to corrosion. Still, they can be more expensive and require careful handling during assembly.

Material selection should consider the operational environment. Temperature fluctuations and exposure to chemicals can affect performance. Testing materials before finalizing choices can be insightful. Engineers should not overlook these factors. Choices should align with the expected workload. The wrong material can lead to failures and costly downtime. These reflections are necessary for optimal performance and longevity.

How to Choose Hydraulic Cylinder Parts for Optimal Performance? - Selecting the Right Materials for Hydraulic Cylinder Parts

| Part | Common Materials | Properties | Applications |

|---|---|---|---|

| Cylinder Barrel | Carbon Steel, Stainless Steel | High strength, corrosion resistance | Construction equipment, industrial machinery |

| Piston Rod | Chrome Plated Steel | Durable, low friction | Mobile equipment, heavy machinery |

| Seals | Nitrile, Polyurethane | Good sealing performance, oil resistance | Automotive, hydraulics |

| End Caps | Aluminum, Steel | Lightweight, strong | Hydraulic systems, pneumatic systems |

| Hydraulic Fluid | Mineral Oil, Water-based Fluids | Effective energy transfer, cooling properties | Hydraulic systems, industrial applications |

Assessing Compatibility of Hydraulic Components for Optimal Use

Choosing the right hydraulic cylinder parts is crucial for achieving optimal performance.

Assessing compatibility of hydraulic components can be quite challenging. It involves more than just matching part numbers.

You must consider material types, pressure ratings, and operational conditions.

Tip: Always verify material compatibility. For instance, certain seals may degrade in specific fluids.

Take time to research each component thoroughly. Missteps here can lead to failures.

Hydraulic systems operate under various pressures and temperatures. Ensure that the cylinder parts can withstand these conditions.

An oversight in this area can cause significant downtime.

Tip: Regularly check and replace worn parts. A small crack or leak can affect overall performance.

Address these issues promptly to maintain efficiency. Remember, compatibility goes beyond mere fit;

it impacts the entire system's longevity.

Maintenance Tips for Ensuring Longevity of Hydraulic Cylinder Parts

When it comes to hydraulic cylinders, maintenance is key for longevity. Regular inspections can help detect issues early. Look for leaks around seals and fittings. Small leaks can lead to bigger problems down the road.

Tips for keeping your hydraulic cylinder parts in good shape include checking fluid levels regularly. Low fluid can cause overheating and inefficient operation. Make sure to clean all external surfaces. Dirt and debris can enter the cylinder and create wear over time.

Consider using lubricants that are compatible with your hydraulic system. Proper lubrication reduces friction and prevents wear. However, avoid over-lubricating. Too much grease can lead to blockages. Remember to track maintenance schedules. Neglecting this can lead to unexpected failures. Pay attention, and your hydraulic components will serve you better.

Related Posts

-

Understanding the Key Components of Hydraulic Cylinder Parts

-

10 Best Hydraulic Cylinder Parts You Should Know

-

Top 5 Hydraulic Cylinder Parts That Boost Performance and Efficiency in Machinery

-

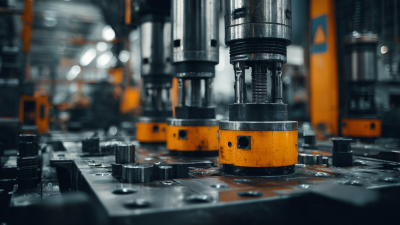

Innovative Solutions for Enhancing Efficiency with Hydraulic Cylinders in Manufacturing

-

Why Understanding Pneumatic and Hydraulic Systems is Essential for Modern Industries

-

Unlocking the Future of Machinery: Innovative Trends in Hydraulic Parts for Enhanced Efficiency

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us