How to Choose the Right Hydraulic Gear Pump for Your Application

In the realm of fluid power systems, the hydraulic gear pump plays a pivotal role, serving as a critical component in numerous applications spanning construction, agriculture, and manufacturing. According to a report by Research and Markets, the global hydraulic pumps market is projected to grow significantly, reaching USD 14.54 billion by 2025, driven by the increasing demand for efficient machinery and equipment in various industries. This growth underscores the importance of selecting the right hydraulic gear pump to ensure optimal performance and reliability in applications where precision and power are paramount.

Selecting the appropriate hydraulic gear pump involves understanding key parameters such as flow rate, pressure rating, and motor compatibility. Industry studies indicate that using the wrong type of hydraulic gear pump can lead to increased operational costs, reduced efficiency, and even premature equipment failure. As the demand for hydraulic systems continues to rise, informed decision-making in pump selection becomes essential to maximize productivity and minimize downtime. By considering the specific requirements of your application, you can better navigate the complexities of hydraulic gear pump selection and harness their full potential in your operations.

Understanding Hydraulic Gear Pump Basics: Types and Functions

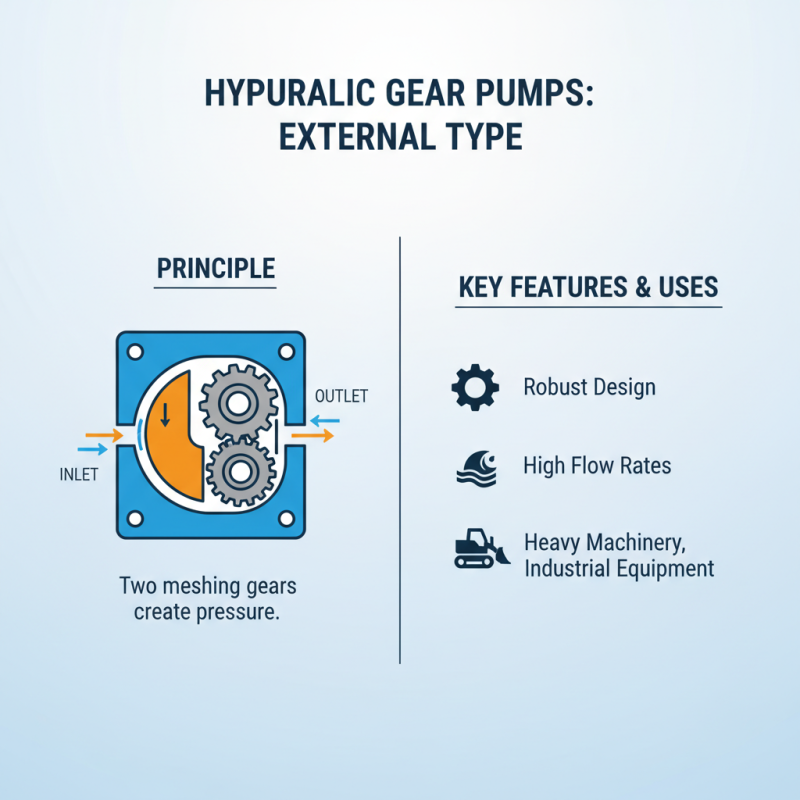

Hydraulic gear pumps are essential components in hydraulic systems, serving various functions depending on their design and type. There are two primary categories of hydraulic gear pumps: external and internal gear pumps. External gear pumps consist of two gears that mesh together to create a cavity where the hydraulic fluid is drawn in and then expelled under pressure. They are known for their robustness and ability to handle high flow rates, commonly used in applications such as machinery and heavy equipment.

On the other hand, internal gear pumps operate differently. They utilize an internal gear that rotates within an outer gear, creating suction and discharge chambers. This design enables internal gear pumps to generate higher pressures and maintain efficiency at lower speeds, making them suitable for applications requiring precise fluid control, such as in manufacturing processes or mobile equipment. Understanding these types of hydraulic gear pumps and their functions is crucial for selecting the right pump for specific operational needs, ensuring optimal performance and reliability in hydraulic systems.

Key Factors in Selecting the Right Hydraulic Gear Pump for Applications

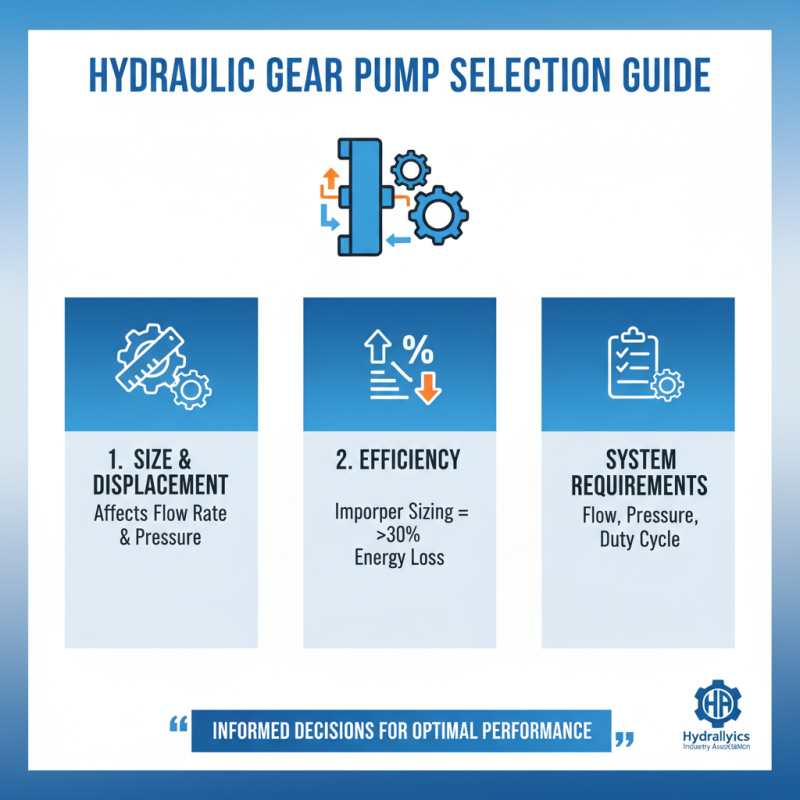

When selecting a hydraulic gear pump for a specific application, several key factors must be taken into consideration to ensure optimal performance and longevity. One critical aspect is the pump's size and displacement, as these parameters directly influence the flow rate and pressure. According to the Hydraulics Industry Association, improper sizing can lead to inefficient operations, resulting in energy losses that may exceed 30%. Therefore, understanding the precise requirements of your system, including flow rate, pressure, and duty cycle, is essential for making an informed decision.

Another important factor is the pump material and design, which determines its compatibility with various hydraulic fluids and operating conditions. For instance, pumps made from high-quality materials like cast iron or hardened steel can withstand the wear and tear of demanding environments, extending their operational life. Moreover, factors like viscosity, temperature ranges, and potential for contamination should be evaluated; reports indicate that fluid properties can significantly affect pump performance and reliability. Manufacturers often recommend conducting a thorough analysis of these elements to ensure the selected pump can handle the specific demands of the application while minimizing maintenance and downtime.

Analyzing Flow Rate and Pressure Requirements for Optimal Performance

When selecting a hydraulic gear pump, understanding the flow rate and pressure requirements of your application is crucial for optimal performance. Flow rate, typically measured in gallons per minute (GPM) or liters per minute (LPM), dictates the volume of hydraulic fluid the pump needs to move within a specific timeframe. For example, standard industrial applications may require flow rates ranging from 10 GPM to over 250 GPM, depending on the operational demands. According to a report by the International Fluid Power Society, accurate matching of flow rates to application needs can improve system efficiency by up to 25%.

Pressure requirements also play a significant role in pump selection. Hydraulic systems often operate under specific pressure ranges, typically from 1500 to 3000 PSI. Exceeding these limits can lead to pump failure and could compromise system integrity. Industry data indicates that hydraulic gear pumps designed for moderate pressures can deliver reliable performance, but advanced applications may necessitate high-pressure systems for optimal operation.

Tips: When choosing a hydraulic gear pump, always consult system specifications and consider conducting a thorough analysis of the load demands. Additionally, ensure that the pump's specifications are in alignment with the hydraulic circuit's design to prevent issues related to cavitation or inadequate lubrication, which can negatively affect performance and longevity.

Material and Design Considerations for Hydraulic Gear Pump Durability

When selecting a hydraulic gear pump, material and design considerations play a crucial role in ensuring durability and efficiency. The choice of materials can significantly affect the pump's resistance to wear, corrosion, and thermal stress. For instance, high-strength steel and advanced alloys are often preferred for their tensile strength and ability to withstand harsh operating conditions. According to a report from the Hydraulic Institute, using pumps manufactured with quality materials can improve lifespan by up to 25%, reducing overall maintenance and operational costs.

Design aspects also contribute to the pump's longevity. A pump designed with a robust casing and precise tolerances minimizes internal wear and enhances fluid flow efficiency. Additionally, features such as enhanced lubrication channels and optimized gear profiles can decrease friction, consequently prolonging the service life of the pump. Research has shown that a well-designed hydraulic gear pump can achieve operating efficiencies upwards of 95%, making design a critical factor in performance beyond just material choice.

**Tips:**

- Always verify the material specifications before purchase; opting for pumps made from corrosion-resistant materials can lead to significant savings in longevity.

- Consider the environmental conditions in which the pump will operate; extreme temperatures or exposure to chemicals should influence your choice of materials and design features.

- Regular maintenance checks can also extend the pump's life—you can prevent major failures with routine inspections and timely repairs.

How to Choose the Right Hydraulic Gear Pump for Your Application - Material and Design Considerations for Hydraulic Gear Pump Durability

| Dimension | Material | Design Feature | Durability Rating | Application Suitability |

|---|---|---|---|---|

| 1.5 in | Cast Iron | Heavy Duty | High | Construction Equipment |

| 2 in | Aluminum Alloy | Compact Design | Medium | Agricultural Machinery |

| 1 in | Stainless Steel | Corrosion Resistant | Very High | Food Processing |

| 2.5 in | Steel | Modular Design | High | Logistics Equipment |

| 0.75 in | Bronze | Lightweight | Medium | Automotive |

Maintenance and Efficiency: Ensuring Longevity in Gear Pump Applications

When selecting a hydraulic gear pump for your application, it’s essential to prioritize maintenance and efficiency to ensure the pump operates effectively over its lifespan. Regular maintenance is crucial, as it helps identify potential issues before they escalate into serious problems. This includes routine inspections for leaks, proper lubrication, and checking the integrity of seals and other components. By adhering to a consistent maintenance schedule, operators can reduce downtime and extend the operational life of the pump, which ultimately leads to reduced overall costs.

Efficiency in gear pump operation is also vital. Ensuring that the pump is appropriately sized for its intended application can prevent excessive wear and tear. Additionally, correct fluid selection and maintaining proper temperature control help to optimize the efficiency of the pump while enhancing performance. Operators should also be aware of the environment in which the pump operates, as conditions such as temperature fluctuations and humidity can impact both maintenance needs and operational efficiency. By focusing on these aspects, users can maximize their hydraulic gear pump’s performance, ensuring reliability and longevity in their applications.

Related Posts

-

Exploring the Versatile Applications of Hydraulic Gear Pumps in Various Industries

-

How to Effectively Perform Hydraulic Repair: Step-by-Step Guide for Beginners

-

Ultimate Checklist for Efficient Hydraulic Pump Repair Maintenance

-

Unveiling Hydraulic Parts Innovations at the 138th Canton Fair 2025 in China

-

Top 10 Hydraulic Pumps: Ultimate Guide to Performance and Efficiency

-

What is Hydraulic Pump Repair and Why It Matters for Industry Efficiency

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us