How to Choose the Right Hydraulic Pumps and Motors for Your Industrial Needs

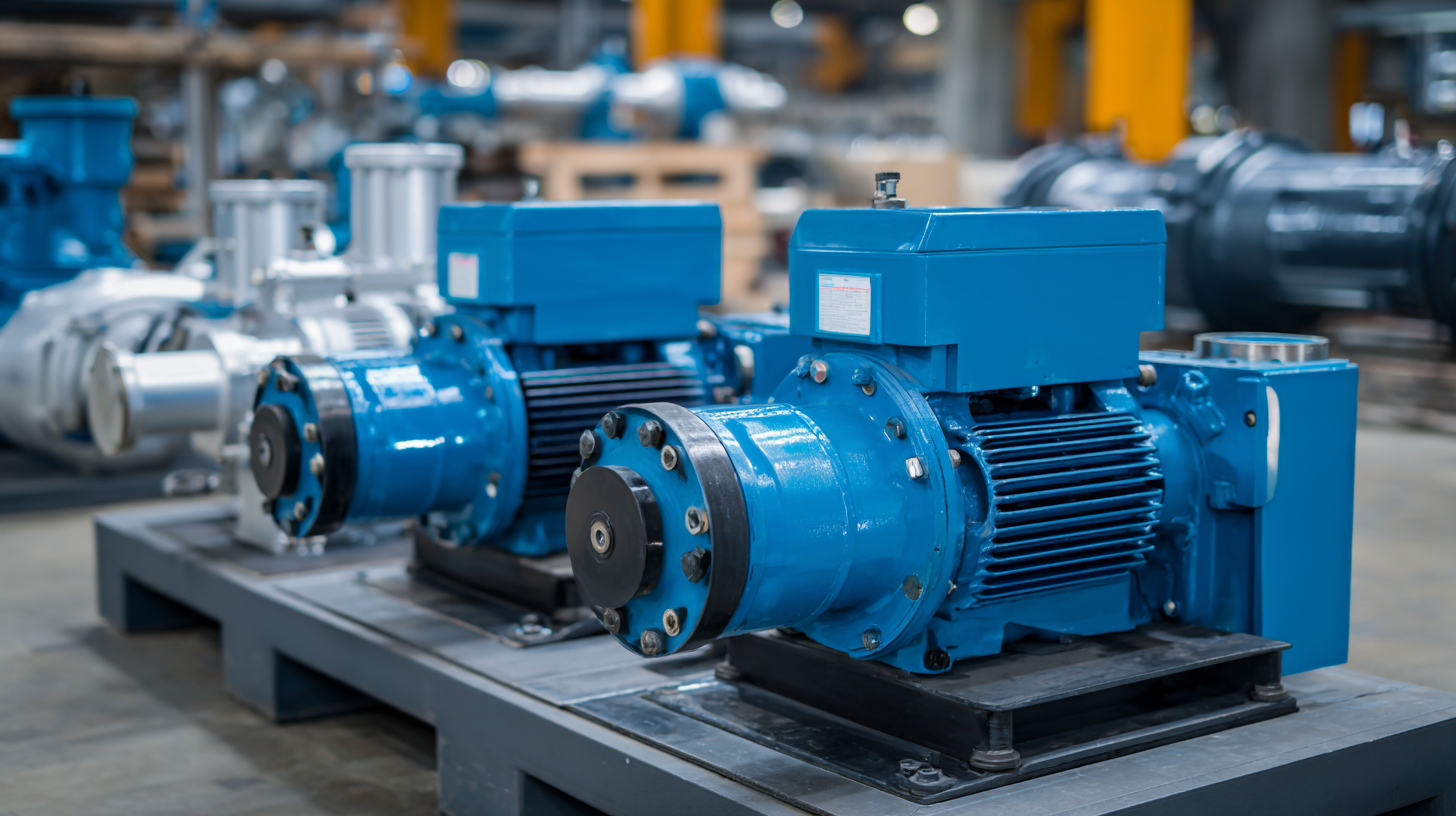

Choosing the right hydraulic pumps and motors for your industrial needs is a crucial step in ensuring optimal performance and efficiency in your operations. With a wide variety of options available in the market, understanding the specific requirements of your application is essential for making informed decisions.

Hydraulic pumps and motors are integral components that drive machinery, providing the necessary power and control for various tasks. Factors such as pressure, flow rate, size, and compatibility with other equipment play a significant role in selecting the appropriate components. In this guide, we will explore key considerations and best practices for selecting hydraulic pumps and motors that not only meet your operational demands but also enhance productivity and reduce downtime in your industrial processes.

Hydraulic pumps and motors are integral components that drive machinery, providing the necessary power and control for various tasks. Factors such as pressure, flow rate, size, and compatibility with other equipment play a significant role in selecting the appropriate components. In this guide, we will explore key considerations and best practices for selecting hydraulic pumps and motors that not only meet your operational demands but also enhance productivity and reduce downtime in your industrial processes.

Understanding Your Hydraulic System Requirements

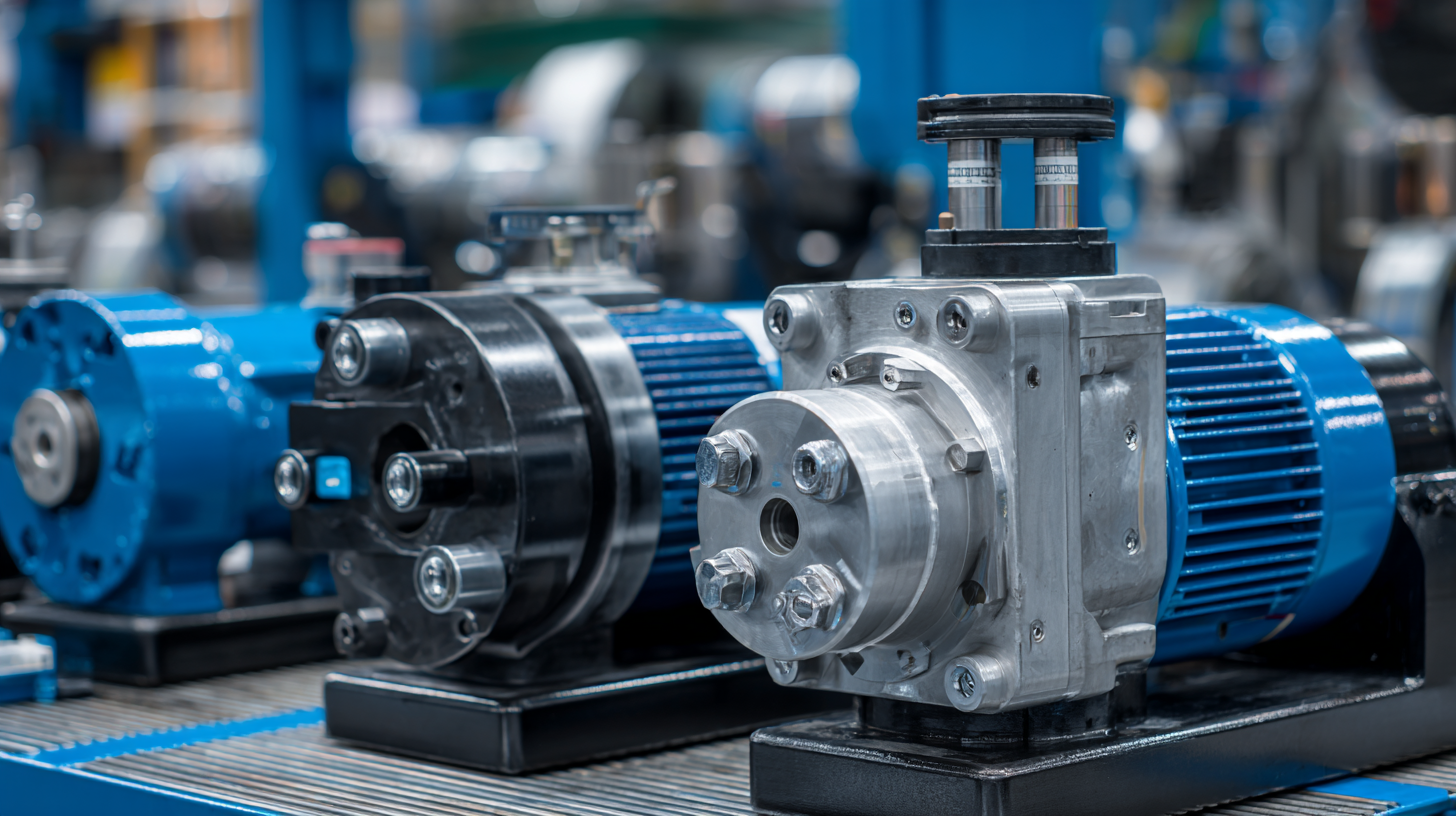

When selecting hydraulic pumps and motors for industrial applications, understanding your hydraulic system requirements is crucial. Begin by assessing the specific demands of your operation, including the necessary flow rates, pressure levels, and operating speeds. Different applications may require distinct types of pumps—gear, vane, or piston—which are each tailored for various pressures and flow characteristics. Evaluating these operational parameters ensures that the selected equipment will perform efficiently and reliably.

In addition to flow and pressure requirements, consider the environmental factors that may influence your hydraulic system. Factors such as temperature variations, exposure to contaminants, and installation space can impact the choice of hydraulic components. Furthermore, understanding the overall system design, including how pumps and motors interact with other hydraulic components, will help in selecting compatible equipment that optimizes performance. By carefully analyzing these requirements, industries can enhance productivity, reduce downtime, and improve overall system longevity.

Hydraulic Pumps and Motors Performance Comparison

Evaluating Different Types of Hydraulic Pumps and Motors

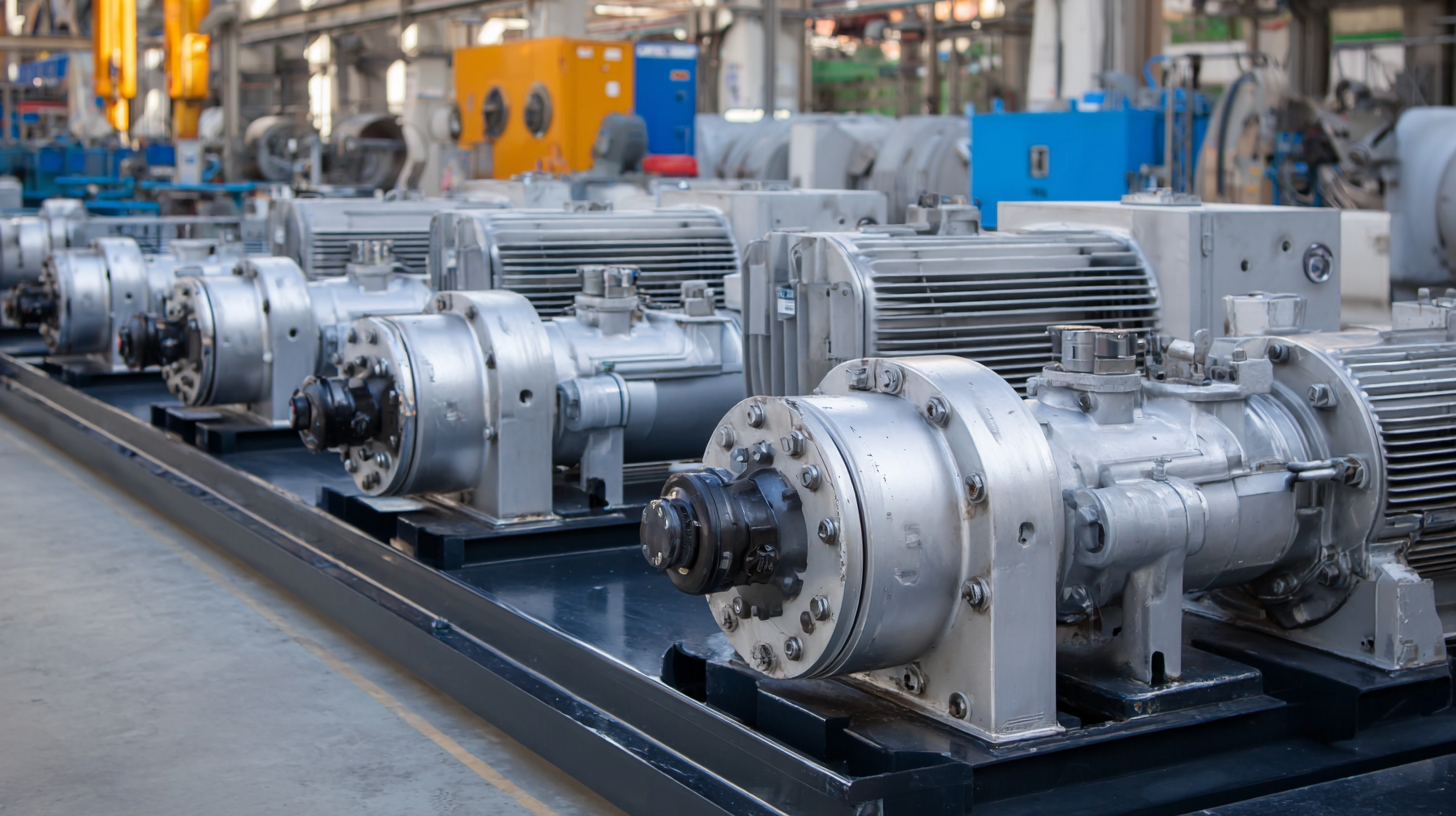

When selecting the appropriate hydraulic pumps and motors for industrial applications, it is crucial to understand the varying types available in the market. The global hydraulics market is projected to reach $44.26 billion by 2030, driven by advancements and innovations in hydraulic technology. Among the latest developments is the introduction of hybrid systems that combine electro-hydrostatic mechanisms with traditional components, enhancing performance in mobile machinery, particularly in off-road applications. This combination not only optimizes efficiency but also promotes energy savings, an essential consideration given the rising demand for sustainable solutions.

In addition to hybrid systems, different pump configurations, such as large vaned-voluted centrifugal pumps, are widely used for large-scale operations like water diversion. Evaluating the performance of these pumps in both pump and turbine modes can provide insights into their operational efficiency, crucial for manufacturing facilities that rely on hydraulic power. The rise in research focusing on valve actuation systems and energy recovery methods reflects the industry's commitment to improving hydraulic performance and reducing environmental impacts, demonstrating the vital role these technologies play in fulfilling modern industrial needs.

Factors to Consider for Size and Capacity Selection

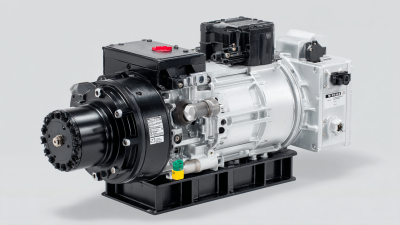

When selecting hydraulic pumps and motors for industrial applications, understanding the factors influencing size and capacity is crucial. Size does not merely refer to physical dimensions; it encompasses the power output, flow rate, and pressure capabilities as well. According to recent energy statistics, the capacity factor is a pivotal element indicating the efficiency of energy generation technologies. For instance, nuclear power plants in the U.S. showcased a capacity factor exceeding 92% in 2024, setting a high standard for operational efficiency which can be analogous to hydraulic systems efficiency in industrial applications.

Moreover, as seen in studies examining capacity determination, such as those involving particle swarm optimization algorithms, it is essential to consider both the environmental variables and operational demands. Hydraulic systems require careful sizing to ensure optimal performance while accommodating fluctuations in supply and demand. Factors like load capacity, urbanization effects, and environmental protection expenditures can similarly impact the selection of hydraulic solutions, underlining the necessity for a comprehensive analysis when specifying the appropriate hydraulic pumps and motors. These considerations together help ensure reliability and operational effectiveness in industrial operations.

How to Choose the Right Hydraulic Pumps and Motors for Your Industrial Needs - Factors to Consider for Size and Capacity Selection

| Factor | Description | Recommended Range |

|---|---|---|

| Flow Rate | Volume of fluid per minute the pump can handle | 5 - 100 GPM |

| Pressure Rating | Maximum pressure the pump can generate | 1500 - 5000 PSI |

| Motor Type | Type of motor used with the pump (Electric vs Hydraulic) | Electric or Hydraulic |

| Pump Type | Type of pump suitable for the application (Gear, Piston, Vane) | Gear, Piston, Vane |

| Mounting Style | How the pump or motor is mounted on the equipment | In-line or Right-angle |

| Application | Specific application that requires the hydraulic system | Construction, Manufacturing, Agriculture |

Assessing Efficiency and Performance Ratings

When choosing hydraulic pumps and motors for industrial applications, efficiency and performance ratings play a crucial role in ensuring optimal operation. Evaluating these metrics requires a thorough understanding of the system's requirements and the specific characteristics of each component. The efficiency of a hydraulic pump, often expressed as a percentage, indicates how effectively the pump converts mechanical energy into hydraulic energy. Higher efficiency ratings generally result in lower energy consumption and reduced operational costs, making it imperative to pay close attention to this factor during selection.

When choosing hydraulic pumps and motors for industrial applications, efficiency and performance ratings play a crucial role in ensuring optimal operation. Evaluating these metrics requires a thorough understanding of the system's requirements and the specific characteristics of each component. The efficiency of a hydraulic pump, often expressed as a percentage, indicates how effectively the pump converts mechanical energy into hydraulic energy. Higher efficiency ratings generally result in lower energy consumption and reduced operational costs, making it imperative to pay close attention to this factor during selection.

In addition to efficiency, performance ratings such as flow rate, pressure ratings, and response time must be assessed. Flow rate determines how much fluid is moved by the pump within a specific timeframe, directly impacting the system's productivity. Pressure ratings indicate the maximum pressure the system can handle, which is vital for applications requiring high force transmission. Lastly, response time reflects how quickly the motor can adjust to changes in demand, which is essential for applications that require precision control. By carefully assessing these efficiency and performance metrics, industrial operators can make informed decisions that lead to enhanced system performance and reliability.

Maintenance and Longevity Considerations for Hydraulic Equipment

Maintaining hydraulic equipment is crucial for ensuring optimal performance and longevity. Regular maintenance tasks include checking fluid levels, inspecting seals and hoses for wear or leaks, and ensuring that filters are clean. These routine checks help to prevent minor issues from escalating into major malfunctions that can lead to costly downtime. Implementing a consistent maintenance schedule allows for proactive intervention, thereby extending the lifespan of hydraulic pumps and motors.

In addition to routine maintenance, choosing the right hydraulic fluids also plays a significant role in the longevity of hydraulic systems. Fluids should be compatible with the materials of the system and should meet the specific operational demands. Quality fluids reduce wear and tear, enhance efficiency, and minimize the risk of overheating. Furthermore, adhering to proper operating conditions, such as avoiding overloads and ensuring adequate cooling, can significantly improve the durability of hydraulic equipment, ensuring that it continues to perform effectively over time.

Related Posts

-

How to Choose the Right Gas Powered Hydraulic Pump for Your Needs

-

How to Optimize Air Hydraulic Pump Performance for Maximum Efficiency

-

Exploring the Versatile Applications of Hydraulic Gear Pumps in Various Industries

-

7 Best Hydraulic Motors for Efficient Energy Solutions in 2024

-

Unlocking Hydraulic Repair Excellence A Comprehensive Guide to Efficient Solutions

-

Top Strategies for Optimizing Hydraulic System Efficiency

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us