How to Choose Between Pneumatic and Hydraulic Systems for Your Projects

In today's industrial landscape, the choice between pneumatic and hydraulic systems can significantly impact the efficiency and performance of a project. As industry expert Dr. Emily Hayes, a renowned engineer specializing in fluid power systems, aptly puts it, "Selecting the right system can mean the difference between a successful operation and costly downtime." Both pneumatic and hydraulic systems have their unique advantages and applications, making the decision process critical for engineers and project managers alike.

Pneumatic systems are often favored for their simplicity, rapid operation, and cleanliness, making them ideal for applications such as packaging and assembly lines. On the other hand, hydraulic systems excel in delivering high power and force in compact designs, which is essential in heavy machinery and automotive applications. This decision not only hinges on the specific requirements of each application but also on factors such as cost, maintenance, and environmental considerations.

As you navigate through the complexities of selecting between these two systems for your projects, understanding the fundamental differences and applications of pneumatic hydraulic technologies will empower you to make informed choices. This guide will provide insights into the critical factors to consider when choosing your suitable system, ensuring optimal results for your engineering endeavors.

Overview of Pneumatic and Hydraulic Systems

Pneumatic and hydraulic systems are two common technologies used in various industrial applications, each with its distinct characteristics and advantages. Pneumatic systems utilize compressed air to generate motion and power. They are often favored for their lightweight components, quick actuation times, and suitability for environments that require cleanliness, such as food processing or pharmaceuticals. Pneumatics are also known for their safety features, as the use of air reduces the risk of fire hazards, making them ideal for specific circumstances where explosive materials may be present.

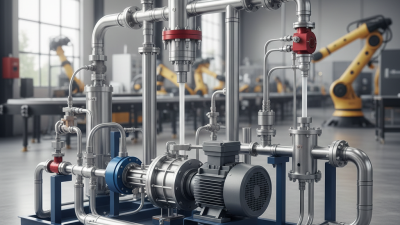

In contrast, hydraulic systems operate using incompressible fluids, typically oil, to transfer power. This allows them to generate significant force and torque, making them suitable for heavy-duty applications, such as construction equipment and manufacturing machinery. The ability to maintain consistent pressure and deliver high power output makes hydraulics ideal for tasks that require precise control and substantial lifting abilities. However, they can be more complex and require rigorous maintenance to avoid fluid leaks and ensure system integrity. Understanding these key differences between pneumatic and hydraulic systems is essential for selecting the right technology for specific project requirements.

Key Differences Between Pneumatic and Hydraulic Technologies

When considering pneumatic and hydraulic systems for various projects, understanding their key differences is essential for making the right choice. Pneumatic systems operate using compressed air, offering advantages such as lightweight components and quicker response times. These systems are ideal for tasks requiring rapid movement and less force, such as in assembly lines or material handling. The inherent cleanliness of air, combined with lower maintenance requirements, makes pneumatic systems suitable for environments where contamination is a concern.

On the other hand, hydraulic systems utilize incompressible liquids, allowing for the transfer of significantly greater forces and torque. This makes them extremely effective for heavy-duty applications, such as in construction machinery and industrial presses. The ability to finely control movements and generate high power within a compact space are other key advantages of hydraulics. However, they may involve more complex maintenance and potential for leaks, which can be a drawback in certain scenarios. Ultimately, the choice between pneumatic and hydraulic technologies hinges on the specific requirements of the project, including force needed, speed of operation, and environmental considerations.

Factors to Consider When Choosing a System

When selecting between pneumatic and hydraulic systems for a project, several key factors must be considered to ensure optimal performance and efficiency. First, the application requirements play a crucial role. Pneumatic systems often excel in applications requiring rapid movement and precise control, such as in packaging machinery or robotics. In contrast, hydraulic systems are better suited for heavy-duty applications where significant force is needed, such as in construction equipment or automotive lifts. Understanding the specific demands of your project will guide you in the right direction.

Another vital factor is the environmental conditions in which the system will operate. Pneumatic systems are generally more adaptable to harsh environments as they do not rely on fluids that could leak and cause contamination. However, they are less efficient in poorly controlled environments, where excessive air humidity can affect performance. Hydraulic systems, while often more powerful, can be influenced by temperature variations that affect fluid viscosity. Considering the work environment and potential challenges will help determine the more appropriate system for your needs.

Comparison of Pneumatic and Hydraulic Systems

This chart compares the performance metrics of Pneumatic and Hydraulic systems across several key factors. Pneumatic systems operate at lower pressure and are generally more cost-effective and easier to maintain, while Hydraulic systems are more powerful but have a higher cost and weight.

Applications Best Suited for Pneumatic Systems

Pneumatic systems are widely used in various applications due to their unique advantages, primarily in environments where clean and lightweight operations are required. One significant application is in the manufacturing and packaging industries, where pneumatic tools such as drills, hoppers, and conveyors facilitate high-speed production. Their rapid actuation capability makes them ideal for tasks that require quick and repetitive movements, enhancing productivity without compromising safety.

Additionally, pneumatic systems are well-suited for material handling applications, particularly in the transport of lightweight items. Their ability to generate a significant force relative to their weight means they can efficiently move products like boxes, bags, or components along assembly lines. Furthermore, because pneumatic systems do not require lubricants that could contaminate products, they are particularly valuable in sectors such as food processing and pharmaceuticals, where hygiene is paramount. Overall, the clean operation, efficiency, and adaptability of pneumatic systems make them a preferred choice for many industries focused on speed and cleanliness in their manufacturing processes.

How to Choose Between Pneumatic and Hydraulic Systems for Your Projects - Applications Best Suited for Pneumatic Systems

| Application | Pneumatic Systems Suitability | Advantages | Disadvantages |

|---|---|---|---|

| Material Handling | High suitability | Lightweight, fast operation | Lower force capability |

| Automated Assembly | Moderate suitability | Quick actuation, simpler maintenance | Less power than hydraulic systems |

| Packaging Machines | High suitability | Speed and precision | Sensitive to dust and moisture |

| Pneumatic Conveying | High suitability | Efficient for bulk materials | Limited range compared to hydraulics |

| Clamping | Moderate suitability | Fast response time | Not suitable for heavy materials |

Applications Best Suited for Hydraulic Systems

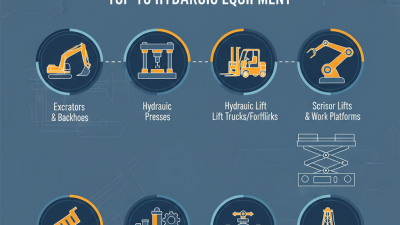

Hydraulic systems offer distinct advantages in a variety of applications, particularly those that require significant force and precise control. These systems utilize incompressible fluids to transmit power, making them ideal for heavy-duty tasks such as construction, manufacturing, and industrial machinery.

For instance, hydraulic systems are widely used in excavators and loaders where high lifting capabilities and robust performance are essential. The ability to generate large amounts of force within a compact profile makes hydraulic solutions particularly beneficial in situations where space is at a premium but power is paramount.

Additionally, hydraulic systems excel in applications demanding sophisticated control mechanisms, such as automotive and aerospace industries. In these sectors, hydraulic actuators and systems support critical operations, including braking systems, flight control surfaces, and convertible mechanisms. Their precision and reliability under extreme conditions make hydraulics a preferred choice where safety and performance are non-negotiable. Moreover, with the capability to maintain high performance over extended periods, hydraulics are often the system of choice in applications that involve continuous operations and require minimal downtime.

Related Posts

-

Essential Pneumatic Hydraulic Maintenance Checklist for Optimal Performance

-

10 Essential Tips for Mastering Pneumatic and Hydraulic Systems

-

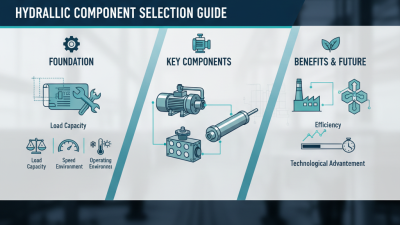

How to Choose the Right Hydraulic Components for Your Applications

-

Top 10 Hydraulic Equipment You Need for Your Business Success

-

The Best 10 Advantages of Pneumatic Hydraulic Systems for Your Business

-

Top 10 Essential Hydraulic System Components for Optimal Performance

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us