How to Choose the Right Hydraulic Components for Your Applications

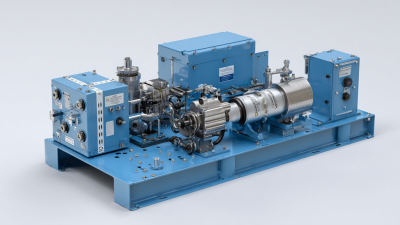

In the ever-evolving realm of industrial applications, selecting the appropriate hydraulic components is crucial for optimizing performance and ensuring longevity. As John Smith, a renowned expert in hydraulic systems, once stated, "The right hydraulic components can significantly enhance the efficiency and reliability of any hydraulic system." This underscores the importance of making informed choices when it comes to components such as pumps, valves, and cylinders, which play pivotal roles in a hydraulic setup.

Understanding the specific requirements of your application is the first step toward securing the right hydraulic components. Factors such as load capacity, speed, and operating environment all influence the selection process. Moreover, with the advancements in technology, there are numerous options available that can cater to specialized needs. Therefore, it becomes imperative for professionals across various industries to stay informed about the available innovations and best practices in hydraulic component selection.

In conclusion, making the right decisions regarding hydraulic components not only boosts operational efficiency but also extends the lifespan of equipment. As industry demands continue to evolve, a strategic approach to selecting these components will ensure that systems run smoothly and effectively, ultimately contributing to the overall success of any hydraulic application.

Understanding the Basics of Hydraulic Systems and Their Components

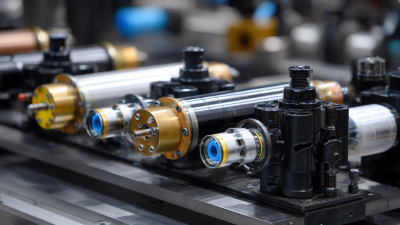

Hydraulic systems are integral to numerous applications across various industries, providing efficient power transfer through the movement of fluids. At the core of these systems are several key components: pumps, actuators, valves, and reservoirs. Understanding the function of each component is crucial for selecting the appropriate parts for specific applications. For instance, hydraulic pumps convert mechanical energy into hydraulic energy, creating fluid flow. The choice of pump depends on the required flow rate and pressure levels, which are determined by the overall system design.

Valves play a significant role in controlling the flow and direction of the hydraulic fluid. By regulating pressure and managing fluid flow paths, they ensure the system operates efficiently and safely. There are various types of valves, such as check valves, relief valves, and directional control valves, each suited for different functions. In addition to pumps and valves, hydraulic actuators convert hydraulic energy back into mechanical energy, enabling movement in machinery. This interplay between components highlights the importance of understanding how they work together to ensure optimal performance in hydraulic systems, ultimately impacting efficiency and productivity in their respective applications.

Identifying Your Application Requirements and Constraints

When selecting hydraulic components for specific applications, understanding the unique requirements and constraints is critical. Industrial reports indicate that improper selection can result in inefficiencies, equipment failure, and increased operational costs, with estimates suggesting that up to 30% of hydraulic system issues stem from incompatible components. A thorough assessment of factors such as pressure requirements, flow rates, temperature ranges, and environmental conditions is essential. For instance, applications operating in extreme temperatures may necessitate components made from specialized materials that can withstand thermal stress, while those exposed to particulates may require filtration systems to maintain system integrity.

Additionally, it is essential to evaluate the spatial constraints of the installation site. Many hydraulic applications are confined to limited spaces, which necessitates components that are not only effective but also compact. Industry analysis from the Fluid Power Manufacturers Association (FPMA) emphasizes that a thoughtful approach to component size and configuration can lead to significant performance improvements. Moreover, understanding the mechanical load and the dynamic behavior of the system under operational conditions can influence the selection of pumps, valves, and actuators. When these elements are systematically analyzed, it enhances the overall reliability and efficiency of the hydraulic system, aligning with the operational goals of businesses in various sectors.

Hydraulic Components Demand by Application Type

Key Factors to Consider When Selecting Hydraulic Components

When selecting hydraulic components for your applications, several key factors must be considered to ensure optimal performance and efficiency. First and foremost, understanding the operational requirements of your system is crucial. This includes factors such as the working pressure, flow rate, and operating temperature. Components must be rated to handle these parameters, as exceeding them can lead to failure or reduced lifespan.

Tip: Always refer to the manufacturer's specifications for each component and cross-check them against your application’s needs to prevent mismatches.

Another important consideration is the compatibility of materials. Different hydraulic fluids can have varying impacts on components made from specific materials. For instance, rubber seals may degrade in certain oils, while metal components can suffer from corrosion without proper coatings. Assessing chemical compatibility ensures that the components maintain their integrity over time.

Tip: Conduct compatibility tests with the fluids you plan to use, or consult material compatibility charts to avoid unexpected issues down the line.

Additionally, factor in the ease of maintenance and availability of parts. Choosing components that are not only reliable but also easy to service can save time and reduce downtime in the long run. This allows for more efficient operations and less interruption to your workflow.

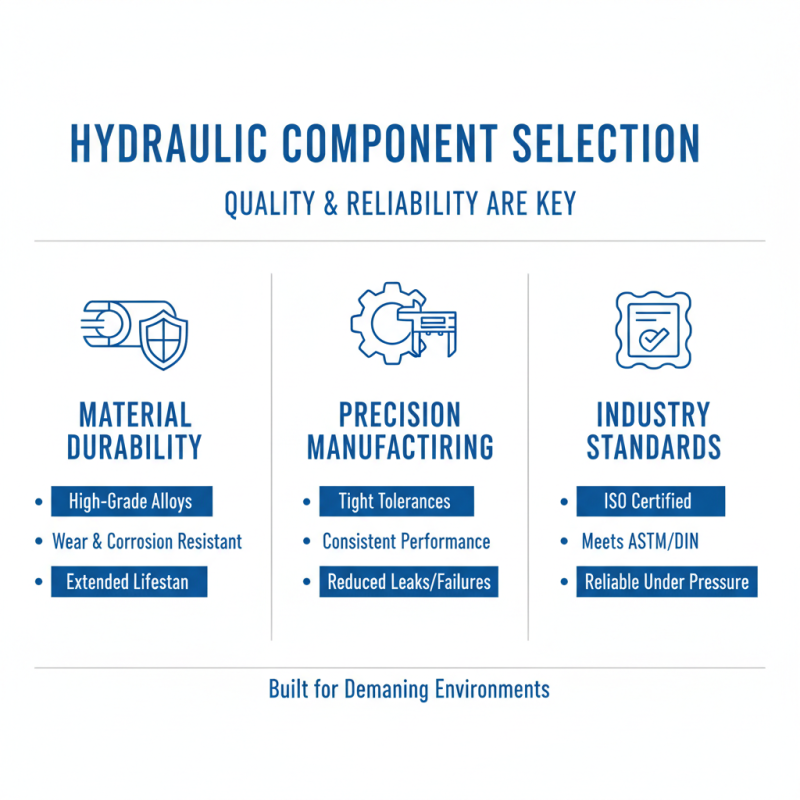

Evaluating the Quality and Reliability of Hydraulic Components

When selecting hydraulic components for your applications, evaluating their quality and reliability is paramount. Hydraulic systems operate under high pressure and must endure demanding environments, making the integrity of each component crucial for overall system performance. To assess quality, consider factors such as material durability, precision manufacturing techniques, and adherence to industry standards. Components made from high-grade materials typically exhibit better resistance to wear, corrosion, and fatigue, which extends their lifespan and ensures consistent operation.

Reliability is another key consideration when choosing hydraulic components. It’s essential to look for components that have demonstrated long-term performance in similar applications. This can often be gauged by examining user reviews, case studies, and historical performance data. Components should also undergo rigorous testing, including pressure cycles and temperature variations, to confirm their reliability under different operational conditions. By prioritizing quality and reliability in your selection process, you can avoid costly downtimes and enhance the efficiency of hydraulic systems.

Common Mistakes to Avoid in Hydraulic Component Selection

When selecting hydraulic components for your application, it is easy to fall into common pitfalls that can lead to inefficiencies and increased costs. One frequent mistake is overlooking the specific requirements of the system. Each hydraulic system has unique characteristics, such as pressure and flow rates, that must be matched appropriately with components such as pumps, valves, and actuators. Failing to consider these specifications can result in poor performance and even component failure.

Another mistake to avoid is neglecting the environmental factors that affect hydraulic components. Factors such as temperature, humidity, and exposure to contaminants can significantly influence the reliability of the system. Choosing components without considering these elements may lead to premature wear and tear or malfunction. Additionally, it's crucial to ensure that all components are compatible with each other; mismatched materials can lead to leaks or ineffective operation. By being mindful of these common errors, you can make more informed decisions and enhance the efficiency of your hydraulic systems.

Related Posts

-

Top 10 Hydraulic Equipment You Need for Your Business Success

-

Understanding the Importance of Hydraulic Components in Modern Machinery

-

Understanding the Power Behind Fluid Power Hydraulics in Everyday Machines

-

Essential Pneumatic Hydraulic Maintenance Checklist for Optimal Performance

-

Innovative Solutions for Fluid Power Hydraulics Efficiency

-

How to Optimize Your Operations with Innovative Hydraulic Solutions

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us