Top Tips for Effective Hydraulic Pump Repair and Maintenance Techniques

Hydraulic pumps play a crucial role in various industrial applications, serving as the heart of hydraulic systems by converting mechanical energy into fluid power. Recent reports indicate that the hydraulic pump market is projected to reach USD 18.94 billion by 2026, growing at a CAGR of 6.2% from 2021 to 2026. This growth emphasizes the importance of not only selecting the right pump but also ensuring its longevity through effective hydraulic pump repair and maintenance techniques.

The maintenance of hydraulic pumps is critical, as even minor inefficiencies can lead to significant operational costs and system failures. Research has shown that approximately 30% of hydraulic pump failures are attributed to improper maintenance practices. By implementing proactive repair measures and routine inspections, industries can reduce downtime and increase the overall lifespan of their hydraulic systems. Therefore, understanding the best practices for hydraulic pump repair is essential for operators aiming to maximize performance and minimize costs in today’s competitive landscape. Proper maintenance strategies not only secure the functionality of hydraulic pumps but also contribute to safer and more sustainable operations across various sectors.

Understanding the Basics of Hydraulic Pumps and Their Functionality

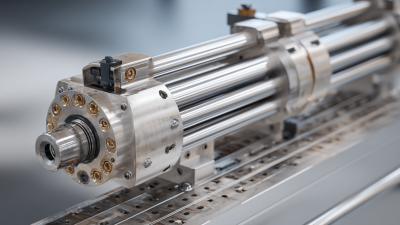

Hydraulic pumps are essential components in various industrial applications, converting mechanical energy into hydraulic energy to power equipment and machinery. Understanding the functionality of these pumps is crucial for effective maintenance and repair. At the core of every hydraulic pump lies the principle of fluid dynamics; they function by creating a pressure differential that allows hydraulic fluid to flow through the system. Different types of hydraulic pumps, including gear, vane, and piston pumps, utilize varying mechanisms to achieve this goal, with each having distinct advantages suited to specific applications.

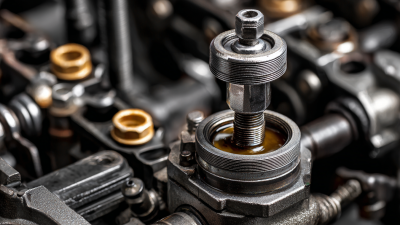

To ensure optimal performance, it is important to grasp the basic components and operation of hydraulic pumps. Key parts include the housing, rotor, and seals, which work together to maintain pressure and prevent leaks. Regular inspection of these components helps in early identification of wear and potential failure points. Proper fluid selection and maintenance also play pivotal roles, as the viscosity and cleanliness of the hydraulic fluid directly influence pump efficiency. By understanding how hydraulic pumps operate and the factors affecting their performance, operators can implement proactive maintenance strategies that prolong equipment life and reduce downtime.

Common Hydraulic Pump Failures and Their Causes

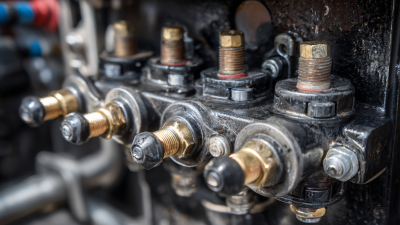

Hydraulic pumps are critical components in various industrial applications, but they can experience several common failures that hinder performance. One prevalent issue is fluid contamination, which can lead to abrasion and wear of internal components. Contaminants such as dirt, water, and metal particles can enter the system, causing blockages and reducing the efficiency of the pump. Regularly monitoring the hydraulic fluid quality and implementing proper filtration systems are essential to mitigate this risk.

Another frequent failure is cavitation, which occurs when there is a drop in pressure within the pump, leading to the formation of vapor bubbles. When these bubbles collapse, they can cause severe physical damage to the pump impellers and casing. Cavitation often stems from inadequate fluid supply, and it is crucial to ensure that the pump is appropriately sized for its application and that the inlet conditions are optimal to maintain a consistent flow of hydraulic fluid. Addressing these common issues through proactive maintenance and repair strategies can significantly extend the life of hydraulic pumps.

Step-by-Step Guide to Inspecting Hydraulic Pumps for Damage

Inspecting hydraulic pumps for damage is a critical component of ensuring their longevity and operational efficiency. Begin the inspection process by visually examining the pump exterior for any signs of wear, such as cracks, corrosion, or leaks. Pay close attention to the connections and seals, as these areas are often prone to damage. Any visible signs of fluid leaks are indicators that seals may need replacing or that the pump might be misaligned, warranting further investigation.

Next, move on to performance checks. Assess the hydraulic fluid level and its condition—contaminated or low fluid can lead to pump failure. Start the pump and listen for unusual sounds, which can signal mechanical issues. Additionally, check for vibration during operation; excessive vibration can indicate imbalances or internal wear.

Finally, use diagnostic tools like pressure gauges and flow meters to evaluate the pump's performance parameters against manufacturer specifications, ensuring optimal functionality. Regular inspections and addressing minor issues promptly can prevent costly repairs and extend the lifespan of the hydraulic pump.

Preventative Maintenance Techniques for Hydraulic Pump Longevity

Preventative maintenance is crucial for extending the lifespan of hydraulic pumps and ensuring they operate at peak efficiency. Regular inspections should be performed to identify potential issues before they escalate. This includes checking for signs of leakage, unusual noises, or changes in performance that may indicate wear or damage. Keeping an eye on fluid levels and quality is also essential, as contaminated or low fluid can lead to serious pump malfunctions. Implementing a routine schedule for checking these elements can help catch problems early and minimize downtime.

Another effective technique involves maintaining the cleanliness of the hydraulic system. Dirt and debris can significantly hinder pump performance and lead to premature failure. It is recommended to frequently change filters and ensure that all components of the hydraulic system are free from contaminants. Additionally, maintaining an optimal operating temperature is vital, as overheating can negatively impact the pump's efficiency and longevity. Utilizing temperature monitoring systems can help keep track of these critical parameters, guiding timely interventions when necessary. By adhering to these preventative maintenance techniques, operators can significantly enhance the durability and performance of hydraulic pumps.

Hydraulic Pump Maintenance Techniques Overview

This bar chart illustrates the recommended frequency of various hydraulic pump maintenance techniques throughout the year. Regular inspections and maintaining a clean environment are critical for ensuring long-lasting hydraulic pump performance.

Troubleshooting Tips for Efficient Hydraulic Pump Repair

When facing issues with hydraulic pumps, effective troubleshooting is crucial to ensure efficient repair and maintenance. The first step in diagnosing a hydraulic pump problem is to gather observational data. Look for signs of unusual noise, vibration, or leaks, as these can indicate underlying issues. Monitoring pressure readings and flow rates can also provide essential insights. For instance, a drop in pressure may suggest internal wear or cavitation, while a sudden increase could indicate a blockage.

Once you've identified potential problems, proceed with systematic analysis. Checking the fluid condition is vital; contaminated or degraded hydraulic fluid can severely affect pump performance. Ensure that filters are clean, and if there's evidence of debris or excessive wear in the pump components, consider a thorough inspection. Additionally, verify all connections and seals for tightness, as loose fittings can lead to pressure loss. By methodically addressing each component and understanding the symptoms, you can execute effective repairs and maintain optimal performance in hydraulic systems.

Related Posts

-

Ultimate Checklist for Efficient Hydraulic Pump Repair Maintenance

-

What is Hydraulic Pump Repair and Why It Matters for Industry Efficiency

-

5 Essential Tips for Best Hydraulic Pump Repair Techniques

-

How to Optimize Pneumatic Hydraulic Systems for Enhanced Performance

-

Innovative Solutions for Fluid Power Hydraulics Efficiency

-

Unlocking the Secrets of Fluid Power Mechanics for Everyday Applications

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us