Unlocking Efficiency: The Ultimate Guide to Hydraulic Power Packs for Modern Applications

In today's industrial landscape, the demand for efficiency and productivity has never been greater, driving innovations in numerous sectors.

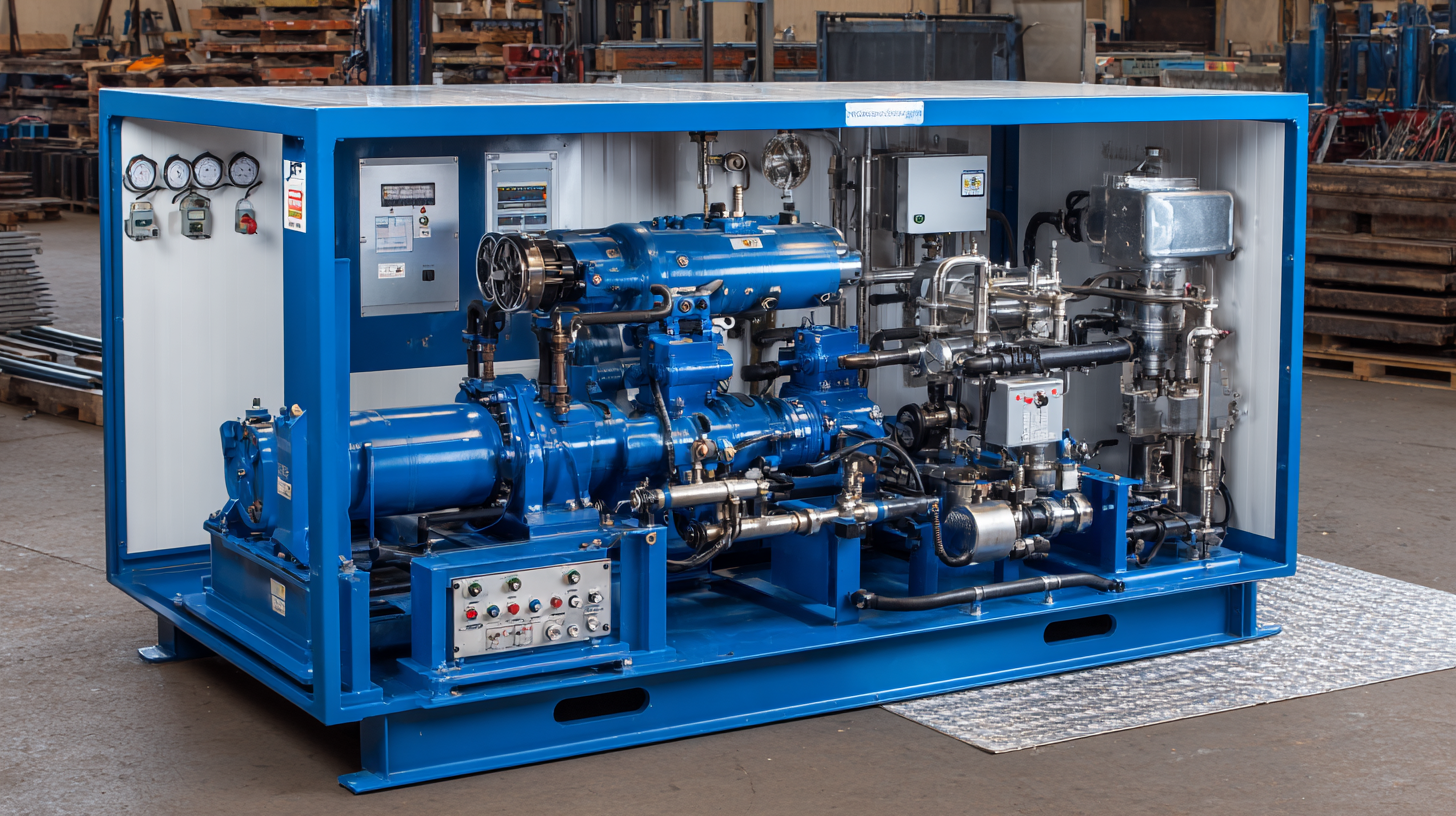

Hydraulic power packs have emerged as pivotal components in various applications, from construction to manufacturing. According to a report by MarketsandMarkets, the global hydraulic equipment market is projected to reach USD 51.58 billion by 2025, with hydraulic power packs playing a significant role in this growth. These versatile systems are designed to convert mechanical energy into hydraulic energy, providing superior performance and reliability. Moreover, their compact design and adaptability make hydraulic power packs ideal for modern applications where space and efficiency are critical. As industries continue to evolve, understanding the functionalities and specifications of hydraulic power packs will be essential for businesses aiming to enhance operational efficiency and maintain a competitive edge.

Hydraulic power packs have emerged as pivotal components in various applications, from construction to manufacturing. According to a report by MarketsandMarkets, the global hydraulic equipment market is projected to reach USD 51.58 billion by 2025, with hydraulic power packs playing a significant role in this growth. These versatile systems are designed to convert mechanical energy into hydraulic energy, providing superior performance and reliability. Moreover, their compact design and adaptability make hydraulic power packs ideal for modern applications where space and efficiency are critical. As industries continue to evolve, understanding the functionalities and specifications of hydraulic power packs will be essential for businesses aiming to enhance operational efficiency and maintain a competitive edge.

Understanding Hydraulic Power Packs: Key Components and Functionality

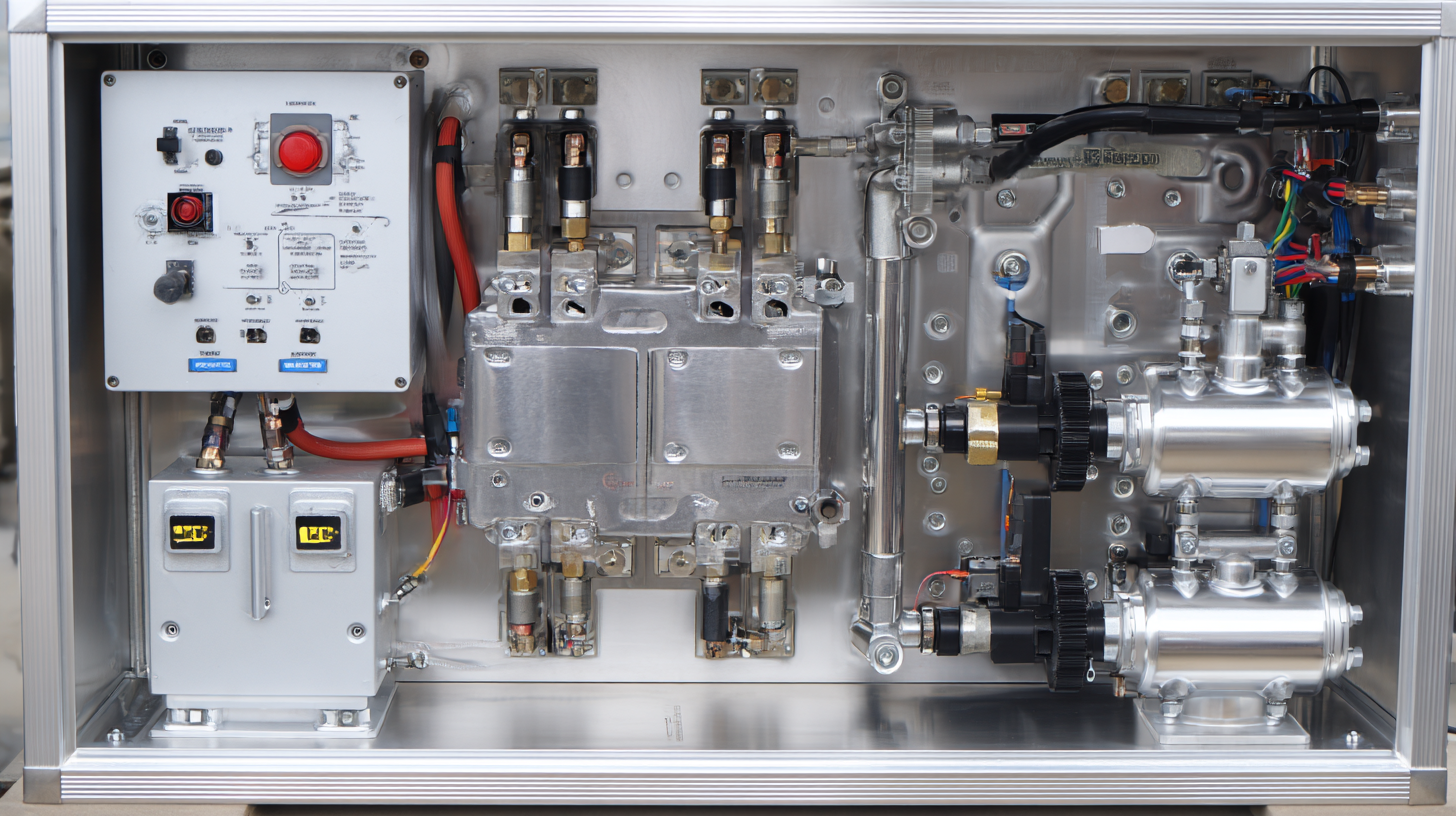

Hydraulic power packs are essential components in modern machinery, driving various applications with efficiency and power. At the core of a hydraulic power pack are key components such as the hydraulic pump, reservoir, valves, and actuator. The hydraulic pump converts mechanical energy into hydraulic energy, allowing fluid to flow under pressure. This pressurized fluid is then stored in the reservoir, ensuring a ready supply for immediate use.

Valves play a crucial role in controlling the direction and flow of the hydraulic fluid, ensuring that the system operates smoothly and safely. These valves can be manually operated or controlled electronically, offering flexibility in operation. The actuator, which can be a cylinder or motor, is responsible for converting the hydraulic energy back into mechanical energy, enabling the movement and control of machinery. Understanding these components and their functionality is vital for optimizing the performance and reliability of hydraulic systems in various applications, from construction equipment to industrial machinery.

Unlocking Efficiency: The Ultimate Guide to Hydraulic Power Packs for Modern Applications

| Component | Description | Functionality | Common Applications |

|---|---|---|---|

| Hydraulic Pump | Device converting mechanical energy to hydraulic energy. | Creates flow and pressure in the hydraulic system. | Excavators, forklifts |

| Reservoir | Storage tank for hydraulic fluid. | Holds fluid and allows for thermal expansion. | Hydraulic systems in machinery |

| Actuator | Device converting hydraulic energy to mechanical work. | Moves or controls mechanisms and systems. | Construction equipment, robotic arms |

| Hydraulic Fluid | Fluid used to transmit power in a hydraulic system. | Transmits power and helps in cooling and lubrication. | Industrial machinery, automotive systems |

| Filter | Removes contaminants from hydraulic fluid. | Ensures clean fluid for optimal system performance. | Hydraulic systems in various machinery |

The Advantages of Hydraulic Power Packs in Modern Industrial Applications

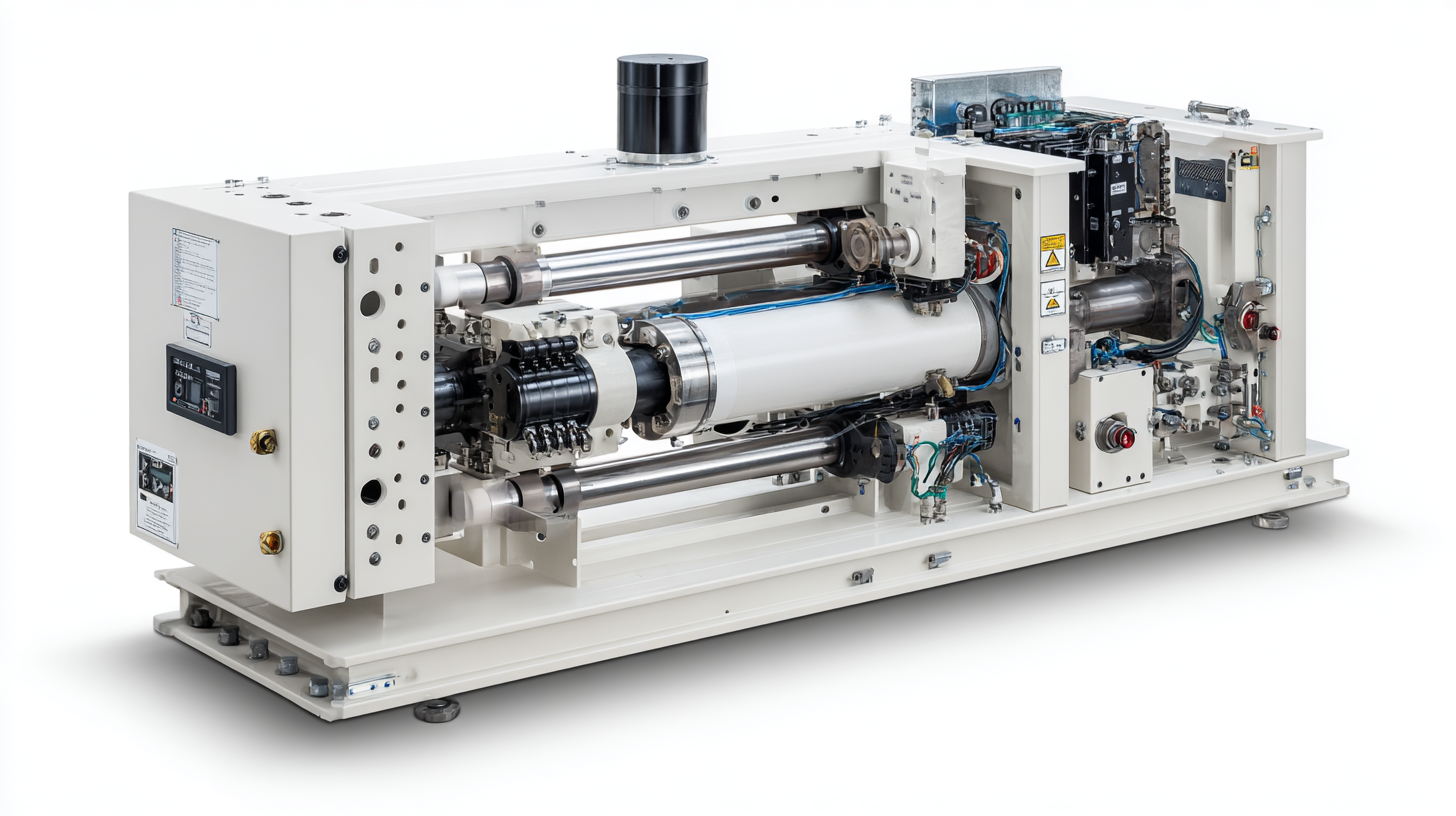

Hydraulic power packs have revolutionized modern industrial applications, offering unmatched efficiency and versatility. These compact systems use hydraulic fluid to transmit power, enabling machines and tools to perform complex tasks with ease. One key advantage of hydraulic power packs is their ability to generate high force output while maintaining a relatively small physical footprint. This characteristic makes them ideal for industries ranging from construction to manufacturing, where space and power efficiency are critical.

Hydraulic power packs have revolutionized modern industrial applications, offering unmatched efficiency and versatility. These compact systems use hydraulic fluid to transmit power, enabling machines and tools to perform complex tasks with ease. One key advantage of hydraulic power packs is their ability to generate high force output while maintaining a relatively small physical footprint. This characteristic makes them ideal for industries ranging from construction to manufacturing, where space and power efficiency are critical.

Tips for Maximizing Efficiency with Hydraulic Power Packs: Regular maintenance is crucial for ensuring optimal performance. Always check hydraulic fluid levels and monitor for leaks, as maintaining proper fluid cleanliness can extend the life of your equipment. Additionally, consider utilizing variable speed drives to control the flow and pressure of your hydraulic system, allowing for more precise operations and energy savings.

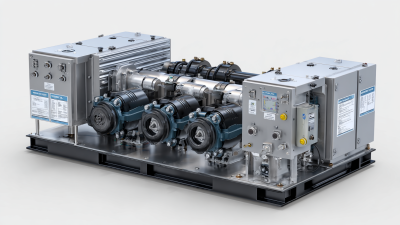

Another significant benefit of hydraulic power packs is their adaptability. They can be tailored to suit specific operational needs, making it easy to integrate into various applications. Whether it's for lifting, pushing, or clamping, these systems can be customized to enhance productivity.

Tip: Invest in hydraulic power packs with modular components that allow for upgrades and scalability, which can be a cost-effective solution as your operational demands evolve.

Selecting the Right Hydraulic Power Pack: Essential Factors and Criteria

When selecting the right hydraulic power pack for modern applications, several essential factors must be considered to ensure optimal performance and efficiency. Firstly, the power requirements of the specific application play a crucial role. It is important to assess the hydraulic power needed, which is typically determined by the flow rate and pressure specifications of the equipment that will be connected to the power pack. A thorough understanding of the operational demands will guide users in choosing a power pack that can deliver the required output without any compromises.

Additionally, the environment in which the hydraulic power pack will operate must be evaluated. Factors such as ambient temperature, humidity, and exposure to contaminants can influence the longevity and reliability of the unit. For instance, power packs used in extreme temperatures may need specialized fluids or components to withstand harsh conditions. Furthermore, portability and installation logistics can also affect the selection process, particularly for applications requiring frequent movement or confined spaces. By carefully weighing these factors, users can make informed decisions that lead to enhanced efficiency and performance in their hydraulic systems.

Innovative Technologies Enhancing Hydraulic Power Pack Efficiency

In modern industrial applications, the efficiency of hydraulic power packs is being significantly enhanced by innovative technologies. One of the key advancements is the integration of smart sensors and IoT capabilities that allow for real-time monitoring and control. These features enable operators to optimize power usage and reduce energy waste by adjusting performance parameters based on operational demands. By utilizing predictive analytics, businesses can also foresee maintenance needs, thereby minimizing downtime and extending the life cycle of the equipment.

Moreover, advancements in materials and design have led to lighter and more compact hydraulic power packs without compromising on performance. Innovative hydraulic fluids that operate effectively at a wider range of temperatures further enhance efficiency, allowing for better performance in diverse environmental conditions. The shift toward modular designs enables customization and scalability, making it easier for industries to adapt to changing requirements while maintaining operational efficiency. Overall, these advancements reflect a significant leap towards maximizing the efficiency of hydraulic power packs, ensuring they remain a vital component in various modern applications.

Unlocking Efficiency: Hydraulic Power Packs Performance Overview

Maintenance Best Practices for Optimal Performance of Hydraulic Systems

Maintenance of hydraulic power packs is essential for ensuring optimal performance in various applications. According to a report from the International Fluid Power Society, regular maintenance can reduce equipment failure rates by about 30%. This highlights the importance of implementing best practices in the upkeep of hydraulic systems.

One key maintenance tip is to regularly check and replace hydraulic fluid. Over time, fluid can become contaminated, affecting the efficiency of the system. The American National Standards Institute recommends changing the hydraulic fluid at least every 1,000 operational hours or annually, whichever comes first. Additionally, keep an eye on system filters, as clogged filters can lead to increased wear and decreased performance.

Another crucial aspect is ensuring proper sealing and avoiding leaks. The National Fluid Power Association reports that up to 10% of hydraulic energy can be lost due to leaks. Regular inspection of hoses and fittings for signs of wear can significantly mitigate this risk. Implementing a routine maintenance schedule that includes these practices can lead to enhanced system reliability and longevity, ultimately boosting operational efficiency.

Related Posts

-

Unlocking Efficiency with Hydraulic Power Packs Understanding Their Impact on Industrial Applications

-

How to Optimize Your Operations with Innovative Hydraulic Solutions

-

Understanding the Essential Role of Hydraulic Power Packs in Modern Machinery

-

How to Optimize the Performance of a Hydraulic Gear Pump

-

Essential Pneumatic Hydraulic Maintenance Checklist for Optimal Performance

-

Pneumatic Hydraulics Versus Traditional Hydraulics A Comprehensive Comparison of Efficiency and Performance

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us