Electric Hydraulic Pump Tips for Efficiency and Maintenance?

In the world of hydraulic machinery, efficiency is key. John Smith, a renowned expert in electric hydraulic pumps, once stated, "Maximizing pump efficiency leads to better performance and lower costs." Understanding the nuances of an electric hydraulic pump is essential for operators and maintenance teams alike.

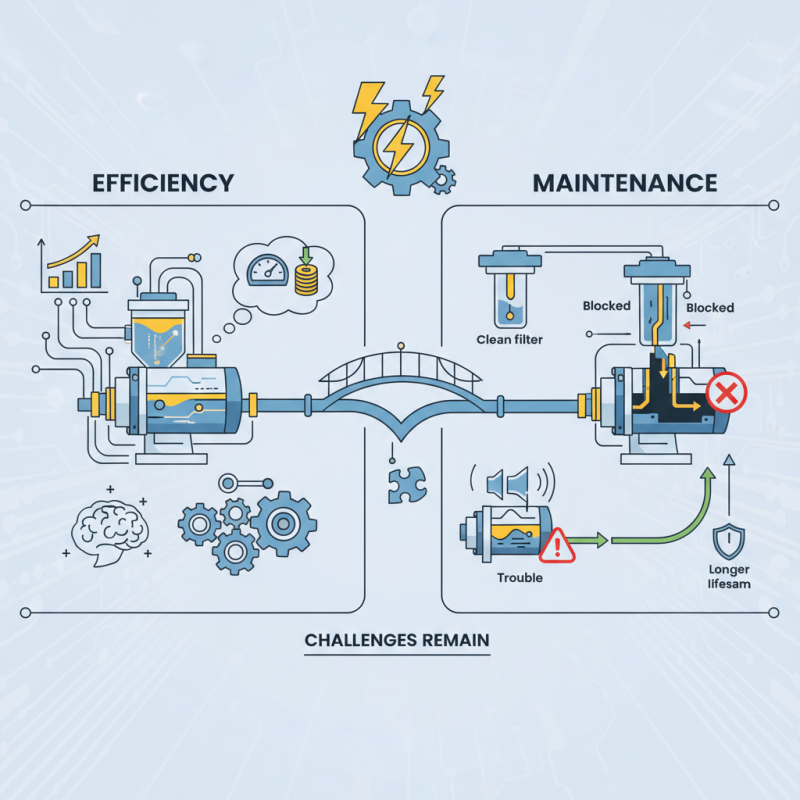

Maintaining an electric hydraulic pump is not always straightforward. Regular checks are vital to prevent failures. Overlooking small issues can lead to significant problems down the line. For example, ensure that filters are cleaned regularly. Blocked filters can reduce efficiency drastically.

Furthermore, operators should be aware of signs that indicate a pump may need repair. Unusual noises or vibrations can signal trouble. These details often go unnoticed until it's too late. By focusing on both efficiency and maintenance, the lifespan of electric hydraulic pumps can be significantly extended, but challenges remain.

Understanding Electric Hydraulic Pumps: A Comprehensive Overview

Electric hydraulic pumps are essential in various industries, providing power for heavy machinery and equipment. These pumps convert electrical energy into hydraulic energy efficiently. According to a report by the Hydraulic Institute, electric hydraulic systems can achieve energy savings of up to 40% compared to traditional hydraulic systems. This efficiency is crucial in reducing operational costs over time.

To maximize efficiency, maintain your electric hydraulic pump regularly. Keep the system clean and free of debris. Regularly check for leaks and seal any that you find. This small step can boost performance significantly. Ensure that all components fit together well; misalignments can cause wear and tear. Also, monitor fluid levels frequently, as low fluids can cause overheating and damage.

It's easy to overlook basic maintenance, but neglecting it can lead to significant issues. Many operators forget to check the motor's operation temperature. High temperatures can indicate problems. Consider keeping a log of maintenance activities to track the pump’s condition over time. This reflective practice can help anticipate problems before they escalate, ensuring a longer lifespan for your equipment.

Key Factors Influencing the Efficiency of Electric Hydraulic Pumps

Electric hydraulic pumps are becoming more common in various industries. Their efficiency is influenced by several key factors. Proper sizing is crucial. A pump that is too large may waste energy, while one that is too small may not meet demands effectively. According to a recent industry report, optimizing pump sizing can improve performance by up to 25%.

Another significant factor is the quality of hydraulic fluid. Contaminated fluid can cause pump degradation and reduce overall efficiency. Regular fluid checks and maintenance help prevent these issues. Studies indicate that maintaining clean hydraulic fluid can increase the lifespan of pumps by 30% or more.

System design also plays a role. Efficient routing of hydraulic lines limits pressure drops and energy loss. A poorly designed system can lead to excessive energy consumption and reduce overall effectiveness. Many operators overlook these details, which can lead to costly downtimes and repairs. Hence, ongoing training on system design and pump operation can be beneficial for teams.

Electric Hydraulic Pump Tips for Efficiency and Maintenance

| Factor | Description | Impact on Efficiency |

|---|---|---|

| Power Source | The quality of the electrical input affects pump performance. | High-quality power sources improve consistency and reduce fluctuations. |

| Fluid Quality | Using the right hydraulic fluid ensures optimal operation. | Improper fluids can lead to increased wear and decreased efficiency. |

| Temperature Control | Maintaining an optimal temperature is crucial for performance. | Excessive heat can reduce the system's efficiency and lifespan. |

| Maintenance Schedule | Regular check-ups and servicing are vital for long-term operation. | Well-maintained pumps operate more effectively and reliably. |

| Pump Size | Choosing the right pump size for the application is essential. | Incorrect sizing can lead to inefficiencies and increased energy consumption. |

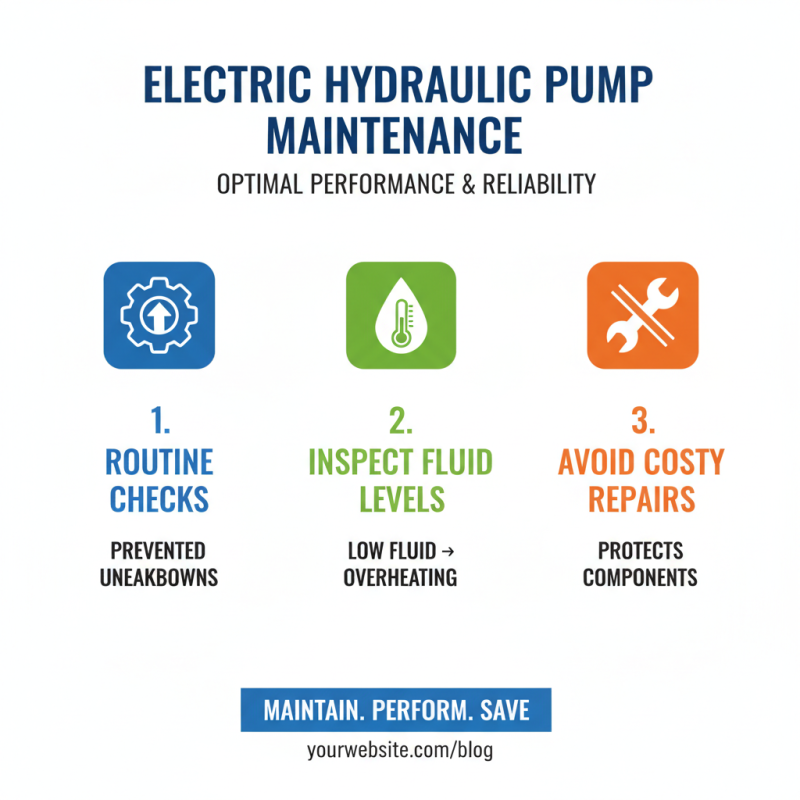

Routine Maintenance Strategies for Optimal Pump Performance

Routine maintenance is crucial for the optimal performance of electric hydraulic pumps. Regular checks can prevent unexpected breakdowns. Inspecting fluid levels is a good starting point. Low fluid can lead to overheating. Overheating damages parts, which can be costly to repair.

Consistent filter cleaning also plays a key role. Dirty filters restrict fluid flow, causing excessive pressure. This pressure can cause leaks. Leaks are not just messy; they can impact efficiency significantly. Keeping the filters clean can extend the pump's lifespan.

Don't forget to monitor connections regularly. Loose connections can lead to hydraulic leaks and system failures. Tightening them should be part of your routine. Many neglect this simple task, leading to frustration later. Creating a checklist can be helpful. A few minutes spent on maintenance can save hours of downtime.

Common Troubleshooting Tips for Electric Hydraulic Pump Issues

Electric hydraulic pumps are essential tools in many industries. When these systems fail, downtime can be costly. Understanding common issues can help you troubleshoot effectively.

One common problem is insufficient pressure output. This may result from a clogged filter or low fluid levels. Regular checks of fluid levels are crucial. Make sure to inspect filters often. Another frequent issue is overheating. If the pump runs too hot, it can cause damage. Ensure adequate ventilation. Avoid placing the pump in confined spaces.

Leakage is also a major concern. Hydraulic fluid leaking can lead to loss of efficiency. Check all connections and hoses regularly. Look for signs of wear or damage. However, sometimes leaks are subtle. You may need to monitor your pump carefully over time. Addressing these issues promptly can improve your pump’s lifespan. Remember, maintenance is key to efficiency.

Best Practices for Enhancing Pump Longevity and Reliability

When it comes to electric hydraulic pumps, enhancing longevity and reliability is key. Regular maintenance ensures smooth operation. Keeping the pump clean prevents dust buildup. Dust can lead to overheating, affecting performance.

Inspect seals and connections often. A small leak can cause significant pressure loss. Replace worn parts promptly. Timely exchanges save costs down the line. Make a habit of checking the hydraulic fluid level. Low fluid can result in pump failure, so never overlook it.

Tips: Use the right fluid for your pump type. Avoid overloading the pump during use. This can lead to premature wear. Lastly, proper storage is vital. Protect your pump from extreme temperatures. Cold or hot conditions can impair its efficiency. Reflect on these practices regularly to ensure optimal performance.

Related Posts

-

2025 Top 5 Hydraulic Pumps and Motors You Need for Optimal Performance

-

2026 Top Air Hydraulic Pump Reviews and Buying Guide?

-

How to Optimize Air Hydraulic Pump Performance for Maximum Efficiency

-

What is Hydraulic Pump Repair and Why It Matters for Industry Efficiency

-

How to Optimize the Performance of Your Hydraulic Pump Motor

-

Unveiling Trends in Electric Hydraulic Pump Demand at China's 138th Canton Fair 2025: Market Insights and Growth Forecasts

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us