The Ultimate Guide to Electric Hydraulic Pumps in 2025 Trends and Innovations

As we venture into 2025, the landscape of energy systems continues to evolve, with electric hydraulic pumps taking center stage in numerous industrial applications. According to a recent report by MarketsandMarkets, the global electric hydraulic pump market is projected to reach USD 3.24 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.8% from 2020. This growth reflects a shift towards more sustainable and efficient hydraulic solutions, driven by advancements in technology and increasing environmental regulations.

Industry expert Dr. John H. Miller, a recognized authority in hydraulic systems, states, “The rise of electric hydraulic pumps not only represents a move towards energy efficiency but also underscores the critical importance of innovation in meeting modern industrial demands.” His insights highlight the key trends shaping the sector, such as the integration of IoT technologies for real-time monitoring and control, leading to enhanced operational efficiency and reduced downtime.

As we explore the trends and innovations surrounding electric hydraulic pumps in this guide, we will uncover the driving factors behind this transformation, the latest technological advancements, and how industries can leverage these developments to optimize their performance and sustainability. The future of hydraulic systems is indeed electric, making this an exciting time for stakeholders across various sectors.

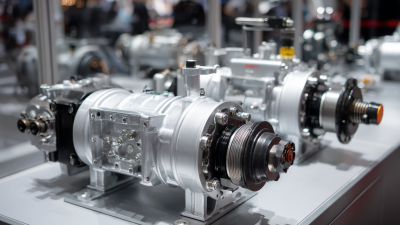

Key Features of Electric Hydraulic Pumps for 2025

Electric hydraulic pumps are poised to undergo significant advancements in 2025, driven by the increasing demand for efficiency and sustainability across various industries. One of the key features of these pumps is their enhanced energy efficiency. With the integration of innovative motor technology and smart control systems, electric hydraulic pumps can optimize energy consumption while delivering consistent power output. This results in reduced operational costs and a lower carbon footprint, making them a preferred choice for environmentally conscious operations.

Another notable trend is the incorporation of advanced monitoring and diagnostic features. These pumps are now equipped with sensors that provide real-time data on performance, allowing for predictive maintenance and minimizing downtime. This shift towards increased automation not only improves reliability but also enhances safety by allowing operators to monitor system status remotely. Furthermore, the design of electric hydraulic pumps is becoming more compact, facilitating easier installation and integration into existing systems, which is essential for industries requiring space-efficient solutions. Overall, these developments highlight a significant move towards smarter, more efficient hydraulic systems in 2025.

Emerging Technologies in Electric Hydraulic Pump Design

As we look towards 2025, the landscape of electric hydraulic pump design is set to undergo profound transformations driven by emerging technologies. These innovations aim to enhance efficiency and reduce environmental impact, responding to the growing demand for sustainable industrial solutions. According to a recent report by Grand View Research, the global electric hydraulic pump market is projected to reach $6.4 billion by 2027, indicating a significant shift towards electric solutions in hydraulic applications.

One of the most notable trends is the integration of IoT (Internet of Things) technology into electric hydraulic pumps. This advancement allows real-time data monitoring and predictive maintenance, maximizing operational efficiency and minimizing downtime. Moreover, developments in lightweight composite materials are leading to more compact and energy-efficient designs. A study from Technavio highlighted that the adoption of advanced materials could improve the performance of electric hydraulic pumps by up to 30%, emphasizing the importance of material science in future designs.

Furthermore, innovations in control systems, particularly those using AI and machine learning, are enhancing the responsiveness and adaptability of electric hydraulic pumps. By utilizing these technologies, manufacturers can create systems that optimize hydraulic fluid flow and pressure dynamically, thereby increasing overall system efficiency. The report indicates that by 2026, smart hydraulic systems could potentially reduce energy consumption by 15-25%, paving the way for a greener future in hydraulic applications.

Environmental Impacts and Sustainability Trends in 2025

As we move into 2025, the environmental impacts of electric hydraulic pumps are becoming increasingly significant, influencing both manufacturing processes and end-user applications. The shift towards cleaner energy sources has prompted manufacturers to focus on innovations that reduce carbon footprints. Advances in battery technology and energy efficiency have allowed electric hydraulic pumps to operate with significantly lower emissions than traditional hydraulic systems, paving the way for more sustainable industrial practices. These pumps can now provide the same level of power and functionality while utilizing greener energy options, reflecting a growing commitment to reducing environmental harm.

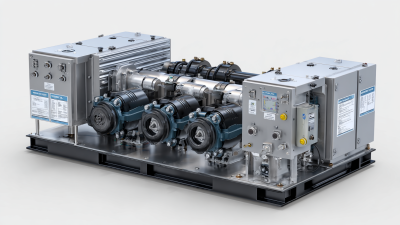

Moreover, sustainability in electric hydraulic pump systems encompasses not only the immediate operational benefits but also the lifecycle impact of these products. Manufacturers are prioritizing recyclable materials and designs that extend the life of components to minimize waste. The adoption of modular designs also facilitates easier upgrades and repairs, contributing to a circular economy. As industries increasingly adopt sustainable practices, the integration of electric hydraulic pumps will play a crucial role in meeting regulatory standards and environmental goals, ensuring that operations contribute positively to the ecosystem while maintaining productivity and efficiency.

The Ultimate Guide to Electric Hydraulic Pumps in 2025 Trends and Innovations

This chart illustrates the predicted trends for electric hydraulic pumps in 2025, focusing on efficiency improvement, emissions reduction, cost reduction, and market growth rate. These indicators reflect the ongoing innovations and the industry's push towards sustainability.

Market Opportunities and Challenges for Electric Hydraulic Pumps

The electric hydraulic pump market is poised for significant growth in 2025, driven by advancements in technology and increasing demand for efficient power solutions across various industries. One of the primary market opportunities lies in the expanding applications of electric hydraulic pumps in sectors such as construction, automotive, and manufacturing. The shift towards greener technologies and the push for energy efficiency have made electric hydraulic pumps an attractive alternative to traditional hydraulic systems, which often rely on fossil fuels. This trend not only aligns with global sustainability initiatives but also caters to the growing market for electrification in industrial operations.

However, despite these opportunities, the market faces challenges that could hinder its growth. The initial investment costs for electric hydraulic pumps can be higher than conventional options, which may deter some companies from transitioning to this advanced technology. Additionally, the integration of electric pumps with existing hydraulic systems can pose technical difficulties, requiring specialized knowledge and resources. As the industry evolves, companies will need to navigate these challenges by investing in research and development, emphasizing training for personnel, and enhancing customer awareness about the benefits of electric hydraulic pumps.

Future Innovations Shaping the Electric Hydraulic Pump Industry

The electric hydraulic pump industry is poised for significant transformation through innovative technologies as we look toward 2025. One of the major trends is the integration of smart technology in electric hydraulic systems. According to a recent report by Market Research Future, the global electric hydraulic pump market is expected to grow at a compound annual growth rate (CAGR) of approximately 7.5% from 2020 to 2026. This growth is largely driven by the increasing demand for efficient and environmentally friendly hydraulic solutions across various sectors, including construction, automotive, and manufacturing.

Another crucial advancement shaping the industry is the development of energy-efficient pumps that minimize power consumption while maximizing performance. These pumps utilize advanced materials and designs that contribute to reduced energy loss and improved operational efficiency. For instance, a study by the International Energy Agency indicates that optimizing hydraulic systems could lead to energy savings of up to 30% in industrial applications. Furthermore, the rise of renewable energy sources is encouraging the adoption of electric hydraulic pumps, which offer cleaner operation compared to their traditional counterparts, aligning with global sustainability goals. As these innovations unfold, they promise to redefine the standards of performance, efficiency, and environmental responsibility in the hydraulic sector.

Related Posts

-

Unveiling Trends in Electric Hydraulic Pump Demand at China's 138th Canton Fair 2025: Market Insights and Growth Forecasts

-

How to Optimize Air Hydraulic Pump Performance for Maximum Efficiency

-

How to Optimize the Performance of Your Hydraulic Pump Motor

-

Unlocking Efficiency with Hydraulic Power Packs Understanding Their Impact on Industrial Applications

-

The Ultimate Guide to Understanding Hydraulic Pumps and Motors for Efficient Machinery Performance

-

Understanding the Essential Role of Hydraulic Power Packs in Modern Machinery

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us