Top 10 Essential Hydraulic System Components for Optimal Performance

In the ever-evolving landscape of industrial machinery, the hydraulic system remains a cornerstone for ensuring optimal performance across various applications. As we approach 2025, manufacturers and engineers are increasingly recognizing the significance of efficient hydraulic systems in enhancing productivity and reducing operational costs. According to a report by the International Fluid Power Society, the global hydraulic systems market is projected to reach $36 billion by 2026, reflecting a compound annual growth rate of 4.5%. This growth underscores the critical role that hydraulic components play in industrial and mobile machinery.

Industry expert Dr. Emily Chang, a renowned specialist in hydraulic technology, emphasizes the importance of understanding the fundamental components of these systems: "The performance of a hydraulic system heavily relies on the integration of its essential components. Neglecting any part can lead to inefficient operation and increased maintenance costs." With a focus on innovation and reliability, it is vital for companies to prioritize their hydraulic systems by utilizing the best components available. This article outlines the top 10 essential hydraulic system components that are crucial for achieving optimal performance and ensuring the longevity of machinery in 2025 and beyond.

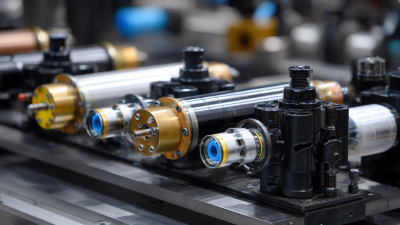

Key Hydraulic Pump Types for Enhanced Efficiency in Modern Systems

Hydraulic pumps play a crucial role in enhancing the efficiency of modern hydraulic systems. The market for hydraulic gear pumps is projected to reach a staggering US$3.2 billion by 2032, indicating a significant rise in demand for high-performance hydraulic solutions. This growth is largely driven by industries that require reliable and efficient hydraulic systems, including construction, agriculture, and manufacturing. Gear pumps, known for their ability to deliver precise flow rates and handle a variety of fluids, are becoming increasingly prevalent due to their robustness and efficiency.

In the aviation sector, the aircraft pumps market is expected to grow at an annual rate of 3.4%, reaching US$8.0 billion by 2034. This growth can be attributed to the rising need for advanced hydraulic systems that support various aircraft functions, from landing gear mechanisms to flight control systems. The focus on reducing weight and increasing fuel efficiency in aircraft design is pushing manufacturers to adopt innovative hydraulic solutions that enhance overall performance while ensuring safety and reliability. As such, understanding the different types of hydraulic pumps and their applications is essential for optimizing system performance across various industries.

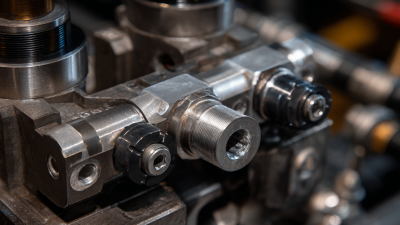

Essential Valves for Precision Control in Hydraulic Applications

In hydraulic systems, achieving precision control is vital for optimal performance, and essential valves play a crucial role in this process. These valves are responsible for regulating the flow and pressure of the hydraulic fluid, ensuring that machinery operates smoothly and efficiently.

Among the key types of valves are directional control valves, which direct the fluid to the appropriate actuator, enabling precise movements of hydraulic cylinders and motors. Their reliable operation is essential for tasks ranging from industrial automation to heavy machinery applications.

Another critical type of valve is the pressure relief valve, which safeguards the system from overpressure conditions. By releasing excess pressure, these valves prevent potential damage to the system and maintain safe operational limits.

Additionally, flow control valves are employed to manage the speed of hydraulic actuators, allowing for smooth and controlled movements. Together, these valves ensure that hydraulic systems can respond accurately to operational demands, underscoring their importance in achieving high-performance standards in various industrial applications.

Top Hydraulic Cylinders to Maximize Force Output and Reliability

When it comes to hydraulic systems, the hydraulic cylinder plays a pivotal role in maximizing force output and ensuring reliability. According to the International Journal of Fluid Power, hydraulic cylinders can produce significant force outputs that surpass those of electric actuators, making them ideal for heavy-duty applications. With advancements in technology, choosing the right cylinder can lead to improvements in efficiency, productivity, and longevity of the equipment.

To select the best hydraulic cylinder, consider factors such as the type of application, the operating pressure, and the required stroke length. For instance, double-acting cylinders are often preferred for applications that require more balanced force delivery and can handle higher loads than single-acting types. Additionally, reports from the Hydraulic Institute indicate that regular maintenance of these components can increase their lifespan by up to 30%, emphasizing the importance of routine checks.

**Tip**: Always ensure that the hydraulic oil used is of high quality and meets the manufacturer’s specifications. This not only enhances performance but also minimizes wear and tear on the hydraulic components. Moreover, when installing hydraulic cylinders, prioritize proper alignment and secure mounting to optimize force generation and prevent premature failures.

Crucial Filters and Separators for Maintaining System Integrity

In hydraulic systems, maintaining system integrity is paramount to ensuring optimal performance and longevity. One of the most critical components in this regard is the filter. According to a report by industry experts at Hydraulics & Pneumatics, a well-designed hydraulic filter can remove particles as small as 5 microns, significantly reducing wear and tear on essential components. Regularly replacing these filters is essential, as clogged filters can lead to reduced flow rates and increased system pressure, compromising efficiency.

Separators also play a vital role in maintaining hydraulic system integrity. They help remove water and other contaminants, preventing them from causing corrosion and malfunctioning in critical hydraulic components. The Hydraulic Institute reports that systems with effective separators can extend component life by up to 40%, further demonstrating the importance of these components. By investing in high-quality filters and separators, industries can not only enhance performance but also ensure reliability in their hydraulic systems, thus minimizing unexpected downtime and maintenance costs.

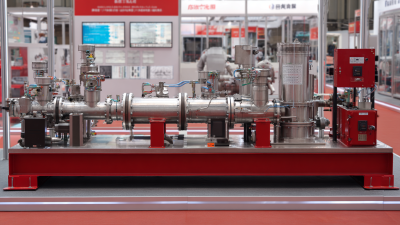

Innovative Hydraulic Accumulators for Energy Storage and Performance Optimization

The efficiency of hydraulic systems heavily relies on the integration of advanced components, particularly innovative hydraulic accumulators. These devices play a crucial role in energy storage and performance optimization. By temporarily storing excess hydraulic energy, accumulators help maintain a consistent flow and pressure in the hydraulic system, ensuring smoother operation and enhanced responsiveness during peak demands. This capability is vital in applications where sudden bursts of energy are needed, such as in construction machinery and manufacturing equipment.

Modern hydraulic accumulators have evolved to include various designs, each tailored to specific operational requirements. For instance, bladder-type accumulators offer efficient gas compression, which aids in absorbing hydraulic shocks and providing a cushion against pressure fluctuations. Additionally, advanced materials and manufacturing processes have resulted in lighter and more durable accumulators, contributing to the overall reliability of hydraulic systems. The strategic use of these innovative components not only improves energy efficiency but also extends the life cycle of the entire hydraulic system, making them indispensable in today’s industrial landscape.

Related Posts

-

Top 10 Benefits of Hydraulic Systems for Modern Machinery Efficiency

-

Understanding the Importance of Hydraulic Components in Modern Machinery

-

Understanding the Essential Role of Hydraulic Parts in Modern Machinery

-

Revolutionizing Hydraulic Systems Trends and Insights at the 138th China Import and Export Fair 2025

-

Unveiling the Future of Fluid Power Hydraulics in Sustainable Engineering

-

Innovative Solutions for Fluid Power Hydraulics Efficiency

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us