Understanding the Essential Role of Hydraulic Parts in Modern Machinery

In the rapidly evolving landscape of modern machinery, hydraulic parts play an indispensable role, significantly impacting efficiency and operational effectiveness across various industries. According to a report by MarketsandMarkets, the hydraulic parts market is projected to reach $XX billion by 2025, indicating a compound annual growth rate of over YY%. This growth underscores the increasing reliance on hydraulic systems in sectors such as construction, agriculture, and manufacturing, where precision and power are paramount.

Dr. John Smith, an industry expert in hydraulic technologies, emphasizes the essential nature of hydraulic parts in machinery maintenance and performance. He states, "The reliability and functionality of hydraulic systems hinge on the quality of the hydraulic parts; they are the heartbeat of any heavy-duty application." This assertion reflects the critical contribution of hydraulic parts to not only enhance productivity but also to ensure safety and longevity of equipment in harsh operational environments.

As we delve into the top 10 hydraulic parts that are shaping the future of machinery, it becomes clear that these components are not merely supporting structures but essential elements that drive innovation and efficiency. Understanding their roles not only aids in selecting the right components but also in predicting the future trends of the hydraulic systems that are vital to industrial growth.

The Significance of Hydraulic Components in Contemporary Equipment

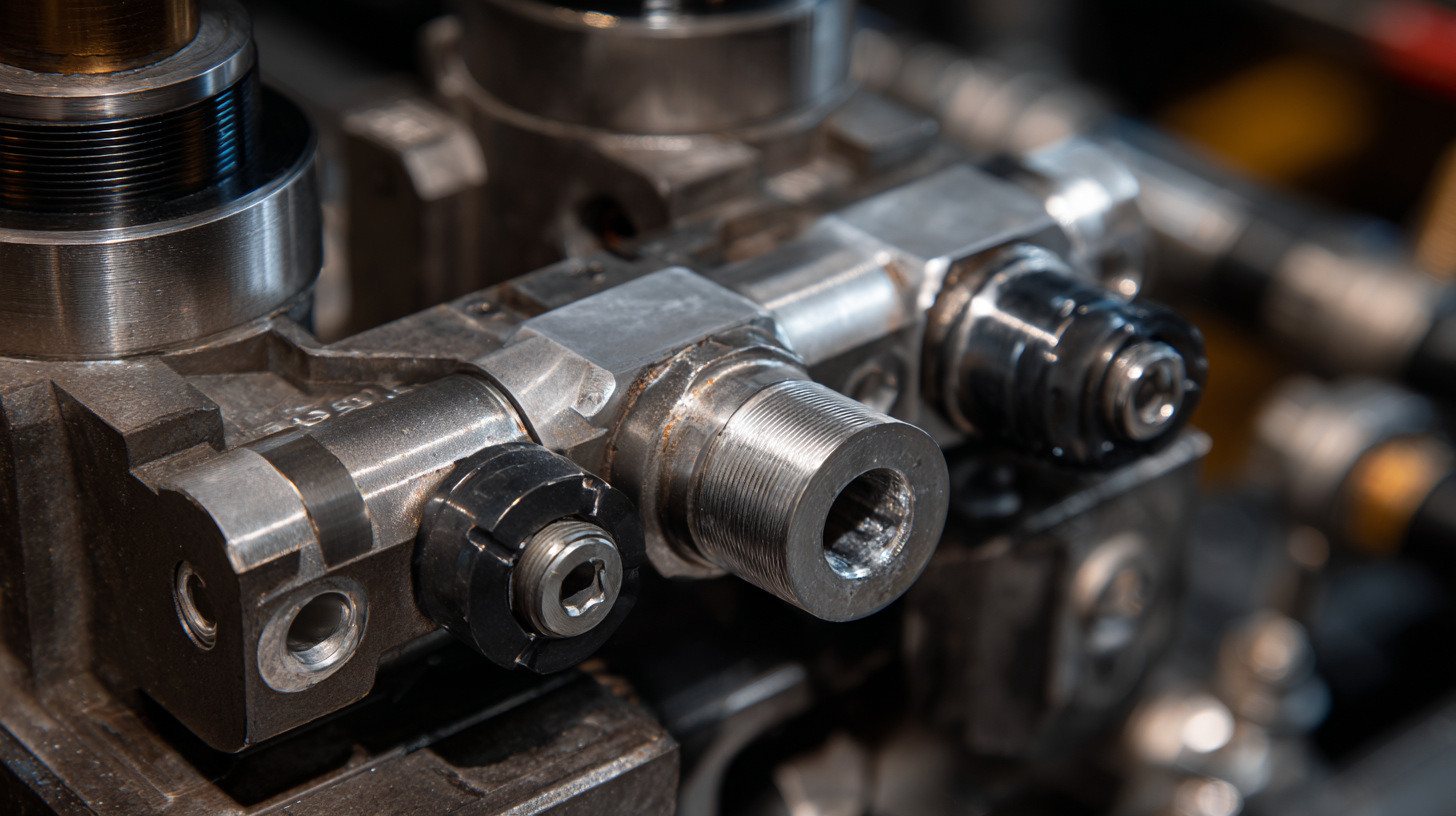

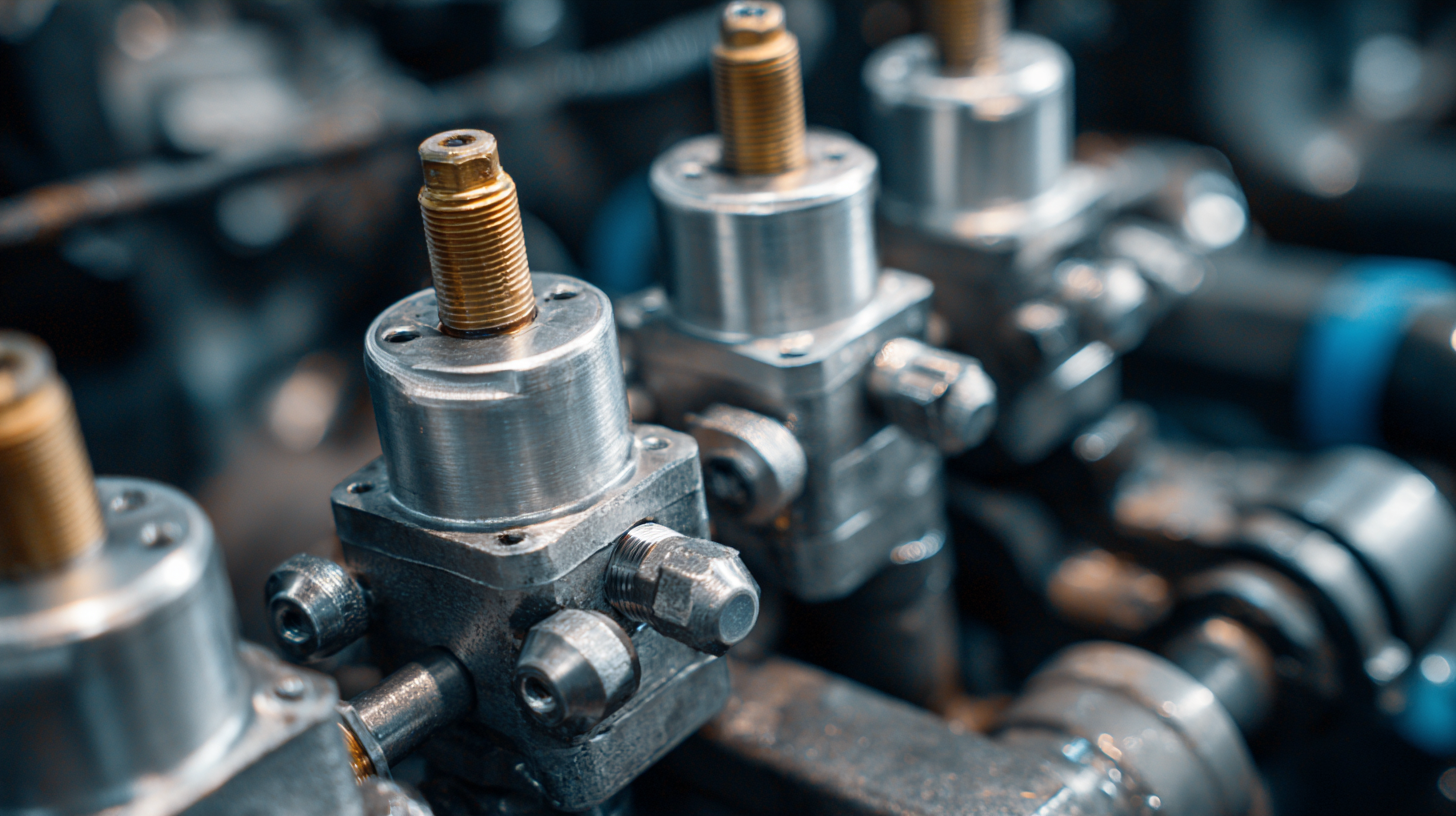

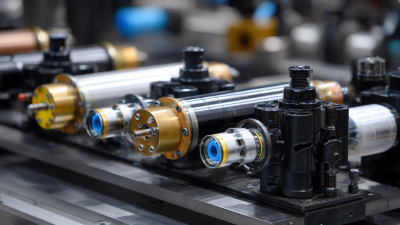

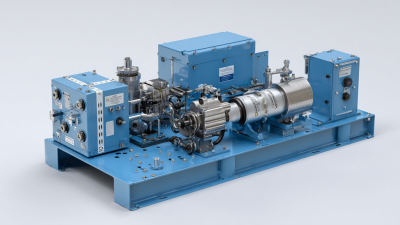

Hydraulic components play a crucial role in contemporary equipment, enabling machinery to perform various tasks with precision and efficiency. These components, including pumps, valves, cylinders, and hoses, work together to convert fluid power into mechanical energy. This capability allows modern machinery to lift heavy loads, execute intricate maneuvers, and maintain stable operations under varying conditions. The reliability of hydraulic systems is integral to industries such as construction, manufacturing, and automotive, where high-performance equipment is essential for productivity.

**Tips:** Regular maintenance of hydraulic components is vital to ensure optimal performance. Checking fluid levels, inspecting for leaks, and replacing worn hoses can significantly extend the life of your hydraulic systems. Additionally, understanding the specific requirements of each component will help in selecting the right replacements, ultimately improving overall machinery efficiency.

Moreover, advancements in hydraulic technology are continuously enhancing the effectiveness of these systems. Innovations such as digital monitoring and energy-efficient designs are contributing to reduced energy consumption and improved responsiveness. By investing in high-quality hydraulic components, businesses can enhance their operational capabilities and achieve better outcomes.

**Tips:** When upgrading hydraulic systems, consider compatibility with existing machinery to avoid costly adaptations. Consulting with professionals can provide tailored solutions that align with your operational needs and improve reliability.

How Hydraulic Systems Enhance Machinery Efficiency and Performance

Hydraulic systems play a critical role in enhancing the efficiency and performance of modern machinery. By utilizing the power of pressurized fluids, these systems can generate significant force in a compact design, allowing for powerful machinery that operates smoothly and effectively. Hydraulic parts, such as pumps, cylinders, and valves, work together to convert energy into motion, facilitating tasks that would be challenging or impossible with mechanical systems alone.

Moreover, hydraulic systems provide precise control over machinery operations, which is essential for tasks that require intricate movements or adjustments. This level of precision not only improves the accuracy of operations but also contributes to the safety and longevity of the equipment. As industrial demands continue to evolve, the integration of advanced hydraulic technologies into machinery design will further enhance operational capabilities, leading to increased productivity and reduced downtime in various sectors.

Key Types of Hydraulic Parts and Their Functions in Industry

Hydraulic parts play a critical role in the functionality and efficiency of modern machinery across various industrial applications. Key hydraulic components, such as pumps, cylinders, and valves, facilitate the transfer and control of hydraulic energy, enabling precise movements and operations in equipment. For instance, the global micro injection molding machine market is projected to grow significantly, from $551.3 million in 2025 to $759.2 million by 2032, underscoring the increasing reliance on sophisticated hydraulic systems in manufacturing processes.

In the realm of power tools, hydraulic technology is also pivotal. The power tools market is expected to witness substantial expansion by 2030, with specific growth driven by hydraulic drilling and fastening tools that enhance operational capabilities. Moreover, adherence to standards such as the ISA-96 series ensures that valve actuators are designed with optimal efficiency and reliability, promoting safety and performance in hydraulic operation. These reports highlight how the integration of advanced hydraulic parts is crucial for maintaining competitiveness and innovation in various sectors.

Challenges and Innovations in Hydraulic Technology for Modern Applications

The landscape of hydraulic technology is continuously evolving, presenting both challenges and innovations that shape modern applications. According to a report by MarketsandMarkets, the hydraulic components market is projected to reach $57.79 billion by 2025, driven by the increasing demand for efficient machinery across various sectors such as construction, manufacturing, and agriculture. However, this growth is accompanied by challenges such as the need for improved energy efficiency and compliance with stringent environmental regulations.

One of the most significant innovations in hydraulic technology is the development of smart hydraulic systems. These systems incorporate IoT sensors and advanced control algorithms to optimize performance and reduce energy consumption. A study from the International Hydraulic Engineering Conference highlighted that smart systems could enhance energy efficiency by up to 30%, significantly lowering operational costs. Additionally, advancements in materials and manufacturing techniques are enabling the creation of lighter, more durable hydraulic components, which can enhance the overall efficiency and reliability of machinery in demanding applications. As the industry continues to innovate, addressing these challenges will be crucial for maintaining competitive advantages in a rapidly changing market.

The Future of Hydraulic Systems: Trends and Predictions in Machinery Design

The future of hydraulic systems in machinery design is poised to undergo significant transformations driven by emerging trends and technology. As industries increasingly focus on efficiency and sustainability, hydraulic systems are adapting to integrate smarter controls and energy-efficient components. The shift towards automation in manufacturing processes is influencing how hydraulic systems are designed and implemented, allowing for real-time monitoring and fine-tuning that minimizes waste and optimizes performance.

Moreover, advancements in materials and design methodologies are paving the way for lighter and more durable hydraulic components. Innovations such as additive manufacturing are enabling the production of complex geometries that enhance fluid dynamics and reduce friction. Additionally, the increasing incorporation of IoT technologies into hydraulic systems allows for predictive maintenance, significantly reducing downtime and maintenance costs. As machinery design continues to incorporate these trends, the role of hydraulic systems will not only remain crucial but will also evolve to meet the demands of a technologically advanced and eco-conscious industry landscape.

Related Posts

-

Understanding the Importance of Hydraulic Components in Modern Machinery

-

Unveiling the Future of Fluid Power Hydraulics in Sustainable Engineering

-

Understanding the Power Behind Fluid Power Hydraulics in Everyday Machines

-

Pneumatic Hydraulics Versus Traditional Hydraulics A Comprehensive Comparison of Efficiency and Performance

-

Innovative Solutions for Fluid Power Hydraulics Efficiency

-

Unveiling Hydraulic Parts Innovations at the 138th Canton Fair 2025 in China

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us