5 Essential Tips for Best Hydraulic Pump Repair Techniques

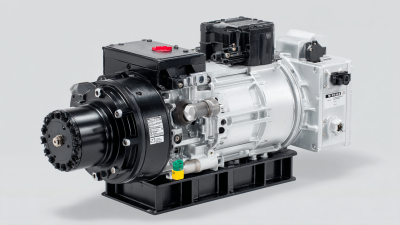

In the realm of machinery maintenance, the efficiency of hydraulic systems largely hinges on the reliability of hydraulic pumps. According to a report by Market Research Future, the hydraulic pump market is projected to reach USD 32 billion by 2025, underscoring the growing significance of these components across various industries. Given their critical role, the hydraulic pump repair process must be executed with precision to avoid costly downtimes and ensure optimal performance. Implementing best practices in hydraulic pump repair not only extends the lifespan of the pump but also contributes to greater system efficiency. This blog aims to equip technicians and engineers with five essential tips for executing effective hydraulic pump repair techniques, ultimately enhancing operational reliability and minimizing disruptions in production workflows.

Choosing the Right Tools for Hydraulic Pump Repair Success

When it comes to hydraulic pump repair, selecting the right tools can significantly impact both efficiency and effectiveness. Studies show that 70% of hydraulic system failures are linked to improper maintenance and repair methods, emphasizing the importance of using specialized equipment. For instance, using precision measurement tools like micrometers and dial indicators can ensure that all components are within manufacturer specifications, reducing the likelihood of future malfunctions.

Additionally, the choice of hydraulic fluid is critical. According to a report from the International Fluid Power Society, nearly 30% of hydraulic system inefficiencies can be traced back to inappropriate fluid selection. Utilizing the right hydraulic oil not only enhances the performance of the pump but also extends its life.

Moreover, having a comprehensive tool kit that includes torque wrenches, seal kits, and hydraulic testers allows technicians to perform repairs quickly and accurately, leading to a more reliable hydraulic system overall. Emphasizing the right tool selection is vital for ensuring long-lasting repairs and optimal performance of hydraulic pumps.

Identifying Common Hydraulic Pump Issues and Their Solutions

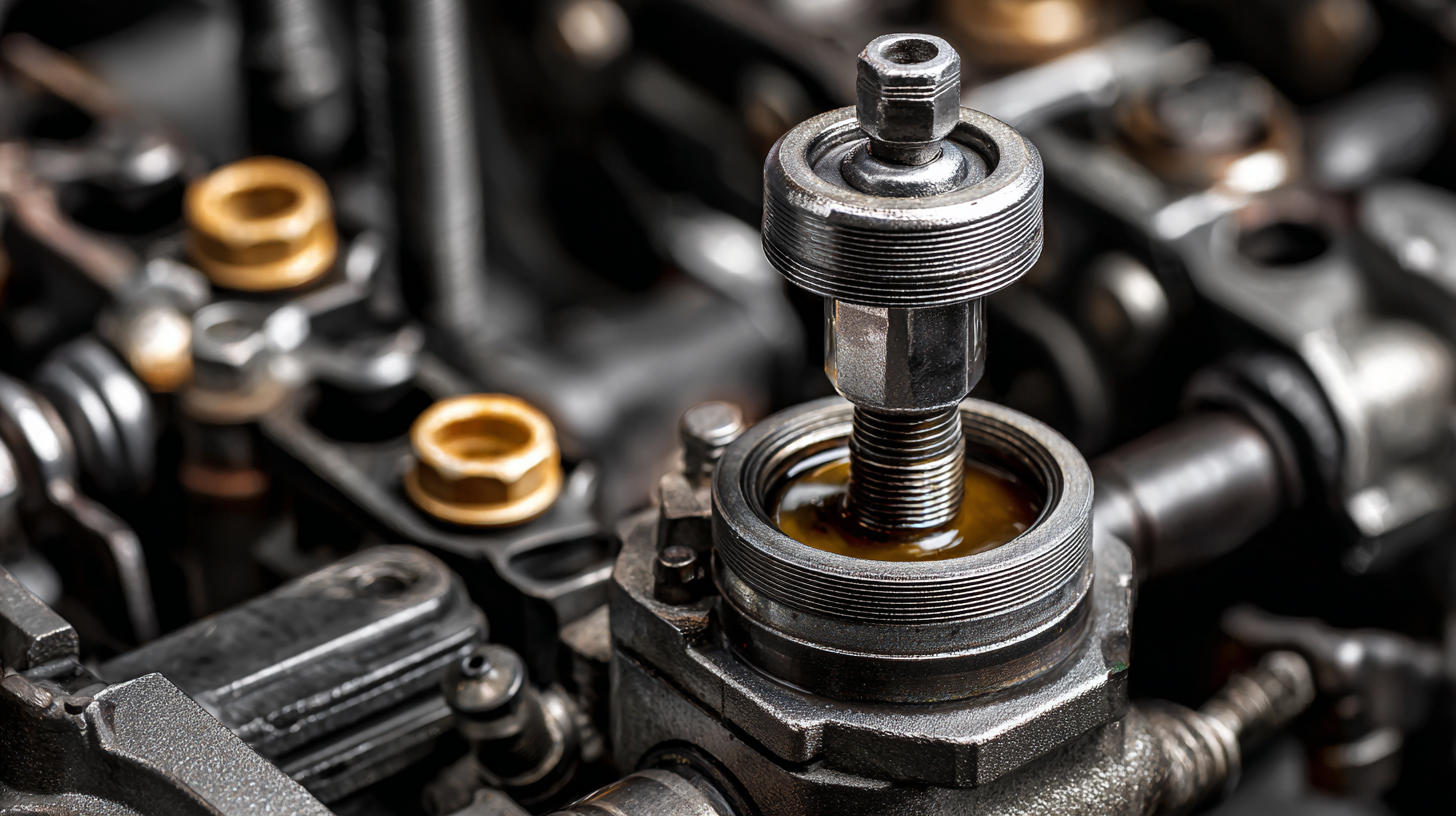

Hydraulic pumps play a critical role in various industrial operations, and understanding common issues can significantly enhance their longevity and performance. One prevalent issue is leaks, which can result from worn seals or damaged fittings. Regularly inspecting these components can help identify leaks early and prevent further damage. Using the appropriate sealant during reassembly can also mitigate the risk of leaks and ensure proper functioning.

Another common problem is low pressure, often caused by air bubbles in the hydraulic fluid or a clogged filter. To address this, clear the fluid lines and replace filters as necessary to maintain optimal flow. Furthermore, overheating is a frequent concern, usually stemming from inadequate fluid levels or inefficient cooling systems. Monitoring the temperature and ensuring proper fluid levels can help keep the hydraulic pump operating within safe limits, ultimately extending its service life and improving efficiency. By focusing on these issues and their solutions, operators can ensure smoother and more reliable pump performance.

Step-by-Step Guide to Disassembling a Hydraulic Pump Safely

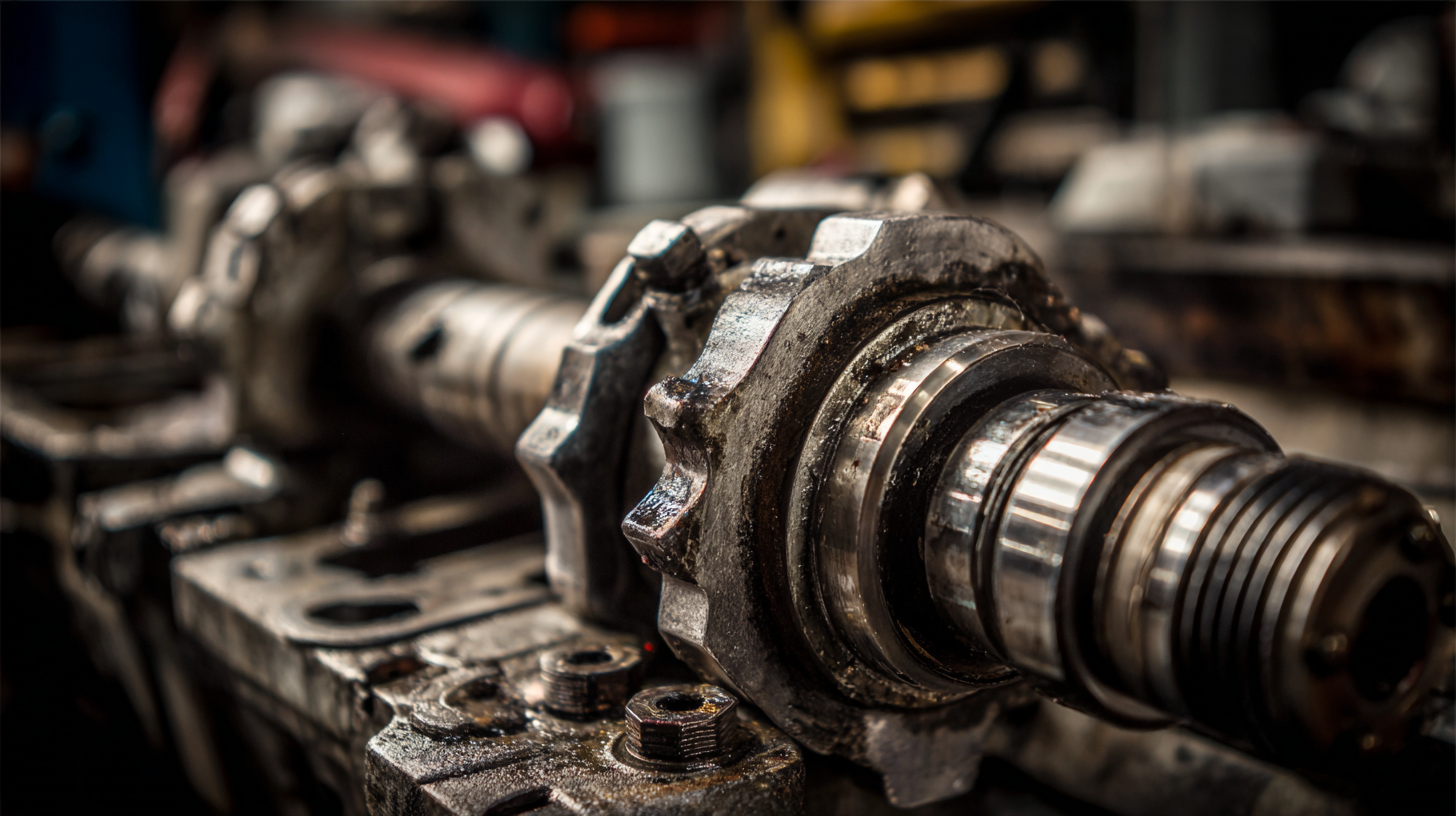

Disassembling a hydraulic pump safely is crucial for ensuring both the integrity of the equipment and the safety of the technician involved. In a recent cautionary tale from a hydraulics lab, a student faced dire consequences while using an improvised apparatus for cylinder rod extraction, highlighting the importance of following proper procedures. Safe disassembly techniques are not just beneficial; they are necessary to prevent accidents that can lead to severe injuries or worse.

To begin disassembling a hydraulic pump, it’s essential to have the right tools and to understand the components involved. According to industry insights, nearly 30% of hydraulic pump failures can be attributed to improper maintenance and disassembly practices. Therefore, meticulously following a step-by-step guide can significantly mitigate risks. This includes isolating the pump from its power source, relieving any pressure, and carefully documenting the order of parts removal to facilitate reassembly.

Moreover, utilizing proper safety equipment—such as gloves and protective eyewear—is vital. Data from the National Institute for Occupational Safety and Health (NIOSH) suggests that injuries involving hydraulic systems can be drastically reduced by adhering to safety protocols. By prioritizing safety and employing structured disassembly techniques, technicians can enhance both their own safety and the longevity of hydraulic systems, ensuring that repairs are not just effective but also secure.

5 Essential Tips for Best Hydraulic Pump Repair Techniques - Step-by-Step Guide to Disassembling a Hydraulic Pump Safely

| Tip Number | Repair Tip | Description | Safety Precautions |

|---|---|---|---|

| 1 | Read the Manual | Familiarize yourself with the hydraulic pump model and repair procedures. | Always wear safety goggles while reading. |

| 2 | Gather Tools | Collect all necessary tools such as wrenches, screwdrivers, and sealant. | Ensure all tools are in good condition to avoid accidents. |

| 3 | Drain Fluid | Properly drain the hydraulic fluid to prevent spills. | Use gloves and dispose of the fluid according to regulations. |

| 4 | Label Parts | Label each part as you disassemble the pump for easy reassembly. | Be cautious of sharp edges on disassembled parts. |

| 5 | Reassemble Carefully | Follow the reverse order of disassembly and ensure all seals are replaced. | Double-check connections to avoid leaks. |

Techniques for Inspecting Hydraulic Pump Components Efficiently

When it comes to inspecting hydraulic pump components efficiently, precision is key. Regular assessments help identify potential issues before they escalate, ensuring optimal performance. According to a report by the National Fluid Power Association, approximately 15% of hydraulic failures can be attributed to improper maintenance and neglect during inspections. Thus, implementing rigorous inspection techniques can significantly reduce downtime and repair costs.

One effective method is to utilize infrared thermography to detect overheating components. This non-invasive technique allows technicians to identify hot spots that may indicate wear or inefficiencies. It’s estimated that early detection through such means can prolong hydraulic pump life by up to 30%. Additionally, adopting the use of vibration analysis can provide insight into the mechanical condition of pump components, allowing for timely interventions.

Tip: Always maintain a clear inspection schedule and document findings to track component health over time. Another useful approach is to incorporate fluid analysis to assess contamination levels, as over 80% of hydraulic system failures are related to fluid cleanliness. By prioritizing these inspection techniques, you can effectively enhance the reliability and efficiency of hydraulic systems.

Best Practices for Reassembling and Testing Hydraulic Pumps

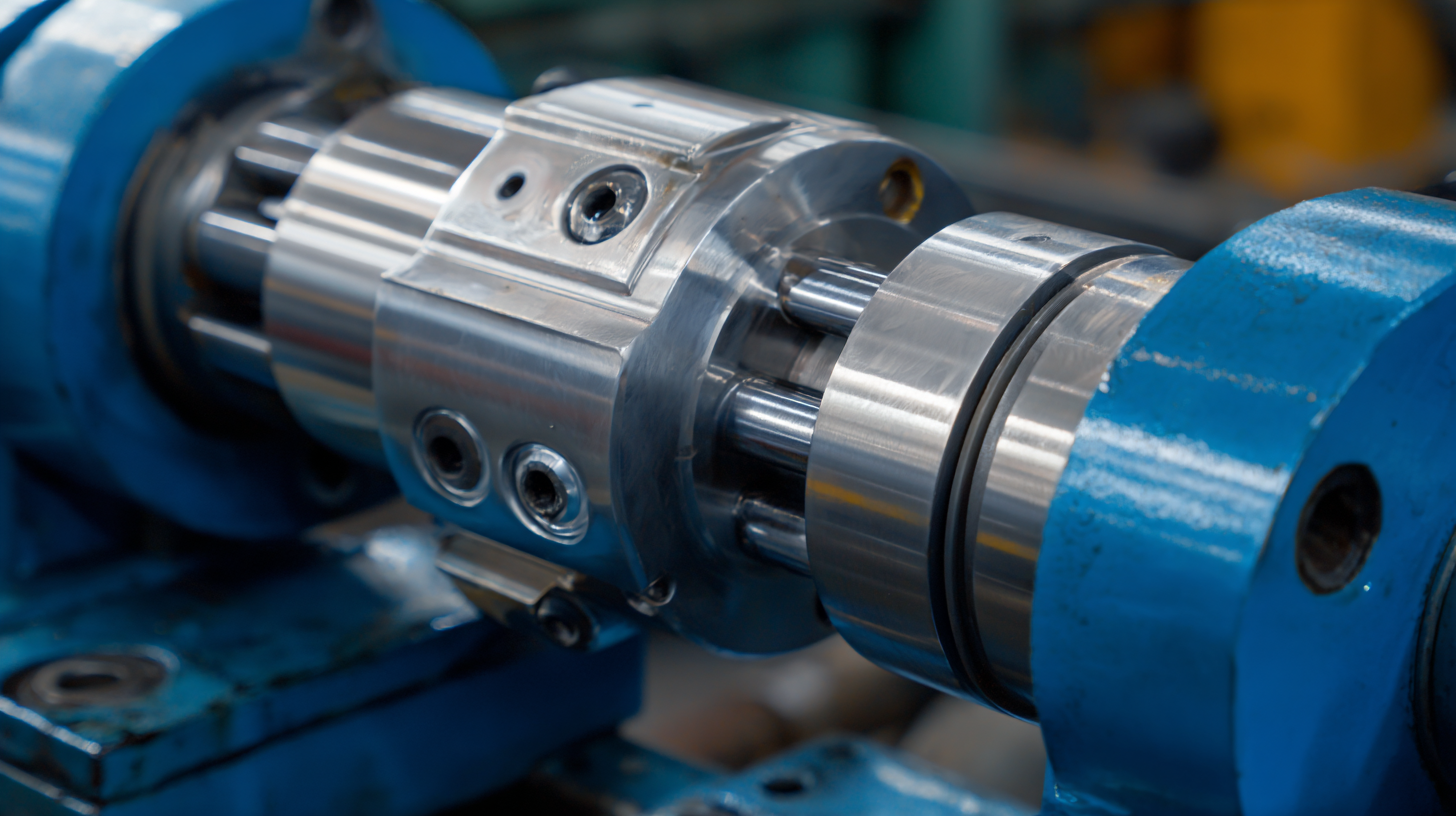

Reassembling and testing hydraulic pumps require a meticulous approach to ensure optimal performance and longevity. When reassembling a hydraulic pump, it is crucial to carefully inspect every component for wear or damage. Begin by cleaning all parts thoroughly, paying particular attention to small crevices that may harbor debris. Using a proper lubricant during assembly minimizes friction and ensures a smoother operation. Double-checking tolerances and aligning components correctly is essential to prevent leaks and ensure efficient function.

After reassembly, rigorous testing is the next step to verify the pump's integrity. Start by conducting a pressure test to ensure that the pump can withstand operational pressures without leaking. Monitor flow rates and check for unusual noises during operation, which may indicate misalignment or internal wear. Additionally, employing diagnostic tools can provide valuable insights into the pump's performance, helping to fine-tune adjustments for optimal efficiency. By following these best practices for reassembling and testing hydraulic pumps, technicians can significantly enhance reliability and operational lifespan.

Related Posts

-

7 Best Hydraulic Motors for Efficient Energy Solutions in 2024

-

Innovative Solutions for Enhancing Efficiency with Hydraulic Cylinders in Manufacturing

-

Top Strategies for Optimizing Hydraulic System Efficiency

-

Exploring the Versatile Applications of Hydraulic Gear Pumps in Various Industries

-

5 Essential Tips for Choosing the Right Hydraulic Pump Motor for Your Industrial Needs

-

Ultimate Checklist for Efficient Hydraulic Pump Repair Maintenance

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us