Understanding the Power Behind Fluid Power Hydraulics in Everyday Machines

In today's rapidly evolving industrial landscape, understanding the power behind fluid power hydraulics is essential for optimizing performance in a wide range of everyday machines. According to the International Fluid Power Society's recent report, the fluid power industry is projected to reach a market value of over $80 billion by 2025, highlighting the critical role of hydraulic systems in various sectors, including construction, manufacturing, and automotive industries. Fluid power hydraulics not only offer superior force and motion control but also enhance operational efficiency, reducing energy consumption by up to 30% in some applications.

As the demand for advanced machinery grows, mastering fluid power hydraulics becomes increasingly crucial for engineers and operators seeking to leverage this technology for enhanced productivity and sustainability. This article delves into the principles of fluid power hydraulics and offers practical insights for effectively employing these systems in everyday machines.

The Basics of Fluid Power Hydraulics: Key Concepts Explained

Fluid power hydraulics is an essential technology that seamlessly operates many everyday machines, ranging from construction equipment to automotive systems. At its core, fluid power hydraulics uses the incompressibility of liquids to transmit energy through confined spaces, allowing for powerful movements with minimal effort. Key concepts include hydraulic force multiplication, where small input forces can translate into substantial output forces, making them ideal for lifting and maneuvering heavy loads with precision.

**Tips:** When working with hydraulic systems, always check for leaks as fluid loss can indicate system inefficiencies. Additionally, regularly maintaining hydraulic oil levels and cleanliness can prolong the life of the machinery and ensure optimal performance.

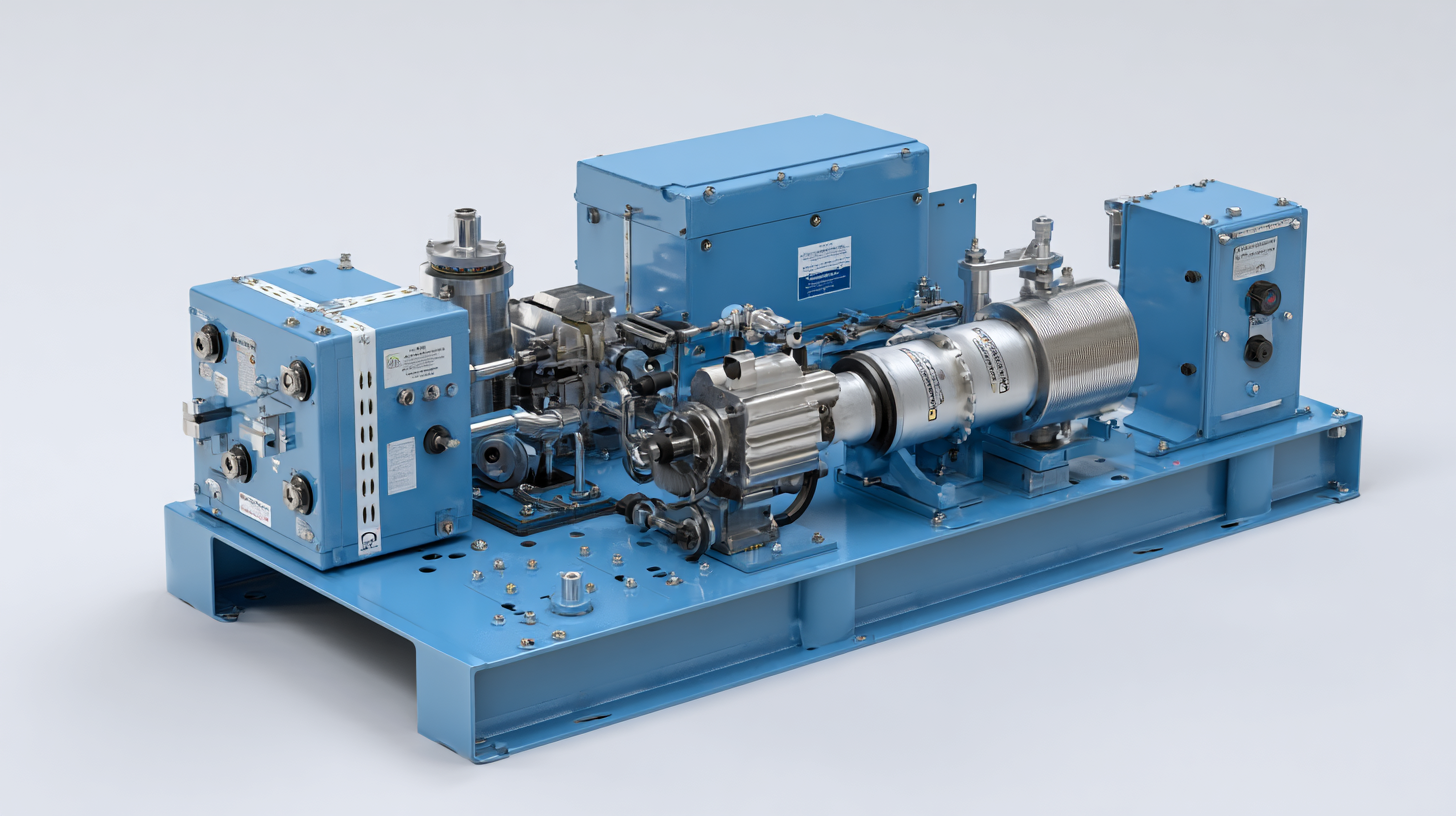

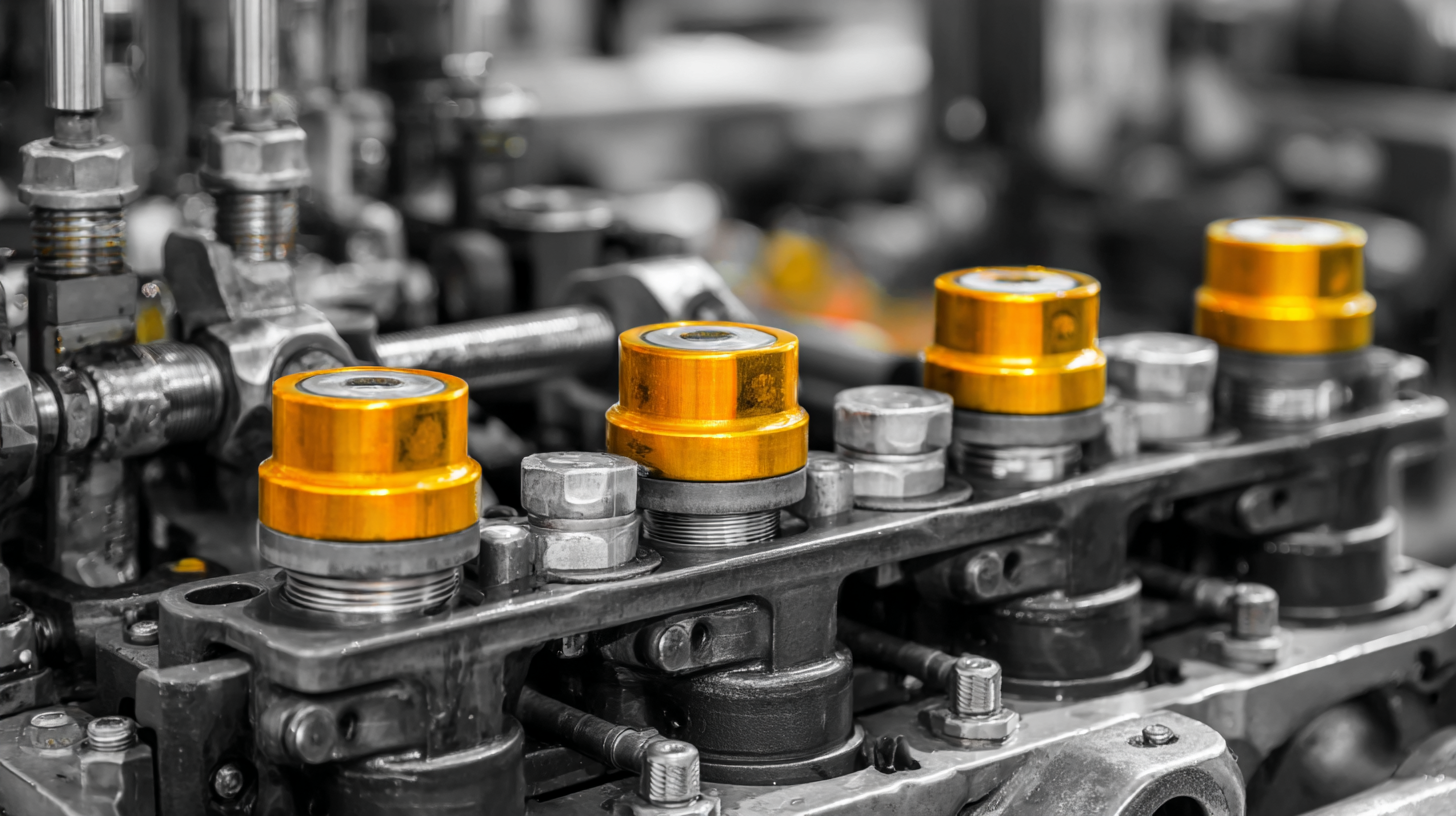

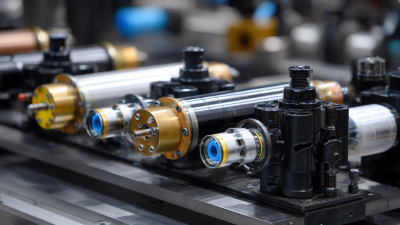

Hydraulic systems employ components such as pumps, cylinders, and valves to control the flow of hydraulic fluid. Understanding how these components interact is vital for anyone working with fluid power technologies. For instance, the selection of the right pump can significantly impact the efficiency and power output of the system, making it crucial to match the pump type with the intended application for best results.

**Tips:** Familiarize yourself with the specifications of hydraulic components before making any replacements. This knowledge can help avoid costly mistakes and ensure your system operates safely and effectively.

Top 5 Applications of Hydraulics in Everyday Machines

Hydraulics play a crucial role in the functioning of various everyday machines, enabling them to perform tasks that would otherwise be challenging or impossible. One of the most prominent applications is in construction equipment, such as excavators and backhoes. These machines rely on hydraulic systems to lift heavy loads, dig deep into the earth, and perform complex maneuvers with precision, thanks to the force multiplication offered by hydraulic fluid.

In addition to construction, hydraulics are essential in the automotive industry, where they are employed in braking systems. The hydraulic brakes provide the necessary force to stop vehicles effectively and safely, utilizing the incompressibility of liquids to transfer force from the brake pedal to the brake pads. Other common applications include agricultural machinery, where hydraulic systems assist in operating various implements like plows and harvesters, and material handling equipment like forklifts, which rely on hydraulics to lift and move heavy goods with ease. Each of these applications showcases the power and versatility of hydraulics in enhancing efficiency and effectiveness in daily tasks.

Understanding the Power Behind Fluid Power Hydraulics in Everyday Machines - Top 5 Applications of Hydraulics in Everyday Machines

| Application | Description | Advantages |

|---|---|---|

| Construction Equipment | Used for lifting, digging, and moving heavy materials on construction sites. | High power-to-weight ratio, precise control, and ability to operate in rugged environments. |

| Manufacturing Machinery | Automates processes like stamping, molding, and assembly lines. | Increases efficiency, reduces manual labor, and improves product consistency. |

| Agricultural Equipment | Enables tasks like planting, harvesting, and tilling through hydraulic lifts and controls. | Enhances productivity, provides versatility, and allows for the use of heavy implements. |

| Automotive Repair Tools | Hydraulic lifts and presses used for vehicle maintenance and repair. | Simplifies heavy lifting, improves safety, and increases efficiency in repairs. |

| Aerospace Systems | Hydraulic systems used in landing gear, brakes, and flight control mechanisms. | Provides reliable operation, high response speed, and weight efficiency. |

How Hydraulic Systems Improve Efficiency in Various Industries

Hydraulic systems play a crucial role in enhancing efficiency across various industries, showcasing their versatility in everyday machines. By utilizing pressurized fluid to transmit power, hydraulic systems enable the seamless operation of equipment ranging from construction machinery to manufacturing tools. This not only increases the speed of operations but also allows for precise control of movements, thereby reducing the likelihood of errors and improving overall productivity.

Hydraulic systems play a crucial role in enhancing efficiency across various industries, showcasing their versatility in everyday machines. By utilizing pressurized fluid to transmit power, hydraulic systems enable the seamless operation of equipment ranging from construction machinery to manufacturing tools. This not only increases the speed of operations but also allows for precise control of movements, thereby reducing the likelihood of errors and improving overall productivity.

In sectors such as agriculture and automotive, hydraulic systems facilitate tasks like lifting, digging, and pressing with remarkable effectiveness. For example, hydraulic excavators use this technology to perform heavy lifting with minimal effort, significantly speeding up construction projects. Furthermore, in the automotive industry, hydraulic brakes and steering systems enhance vehicle performance, ensuring safety and reliability. As industries continue to evolve, the integration of hydraulic systems remains essential for achieving greater efficiency and meeting the demands of modern applications.

Essential Components of Hydraulic Systems and Their Functions

Fluid power hydraulics play a vital role in the functionality of many everyday machines, from construction equipment to agricultural machinery. Understanding the essential components of hydraulic systems is crucial for appreciating their effectiveness. Key components such as hydraulic pumps, actuators, valves, and reservoirs work in unison to transmit power and control motion. According to the National Fluid Power Association, the hydraulic equipment market is expected to grow to $38.8 billion by 2025, reflecting increasing reliance on hydraulic technology across industries.

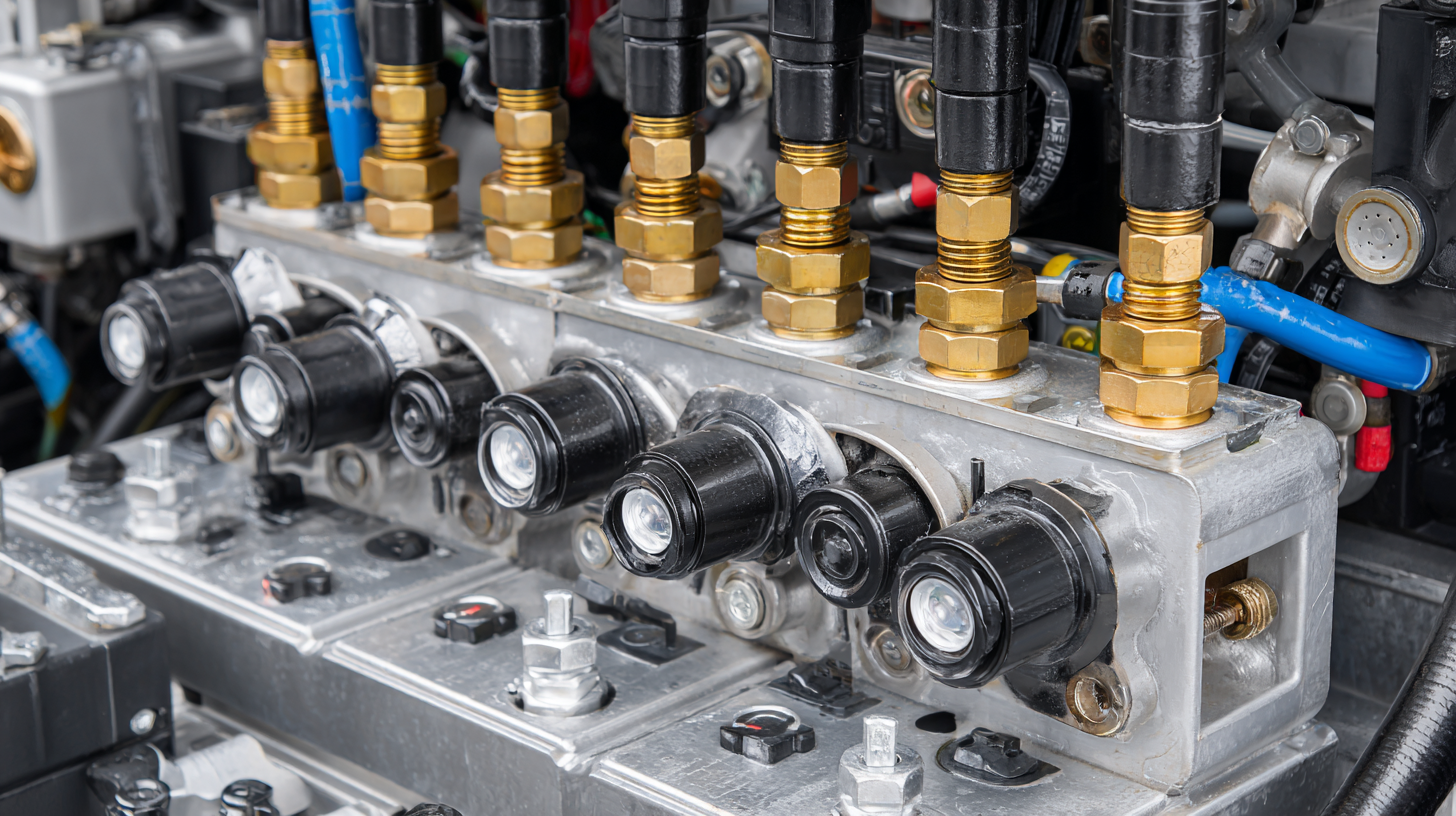

Hydraulic pumps are central to any hydraulic system, converting mechanical energy into fluid energy. They create a flow of hydraulic fluid that is directed to actuators, which produce motion. Valves regulate the system's pressure and flow, ensuring optimal performance for tasks ranging from lifting heavy loads to precise movements in robotics. Fluid reservoirs maintain a consistent fluid level and facilitate the cooling of hydraulic fluid, enhancing the overall efficiency of the system.

Tip: Regular maintenance of hydraulic systems, including fluid checks and filter replacements, can extend the lifespan of equipment significantly. Additionally, monitoring for leaks and pressure anomalies is essential to prevent costly downtime. Ensuring that all components are functioning correctly not only enhances performance but also promotes safety on the job site.

Tips for Maintaining Hydraulic Systems for Optimal Performance

Hydraulic systems are essential in various everyday machines, from construction equipment to automotive braking systems. To ensure these systems operate at peak efficiency, regular maintenance is crucial. One key aspect of maintenance is fluid quality. Properly maintaining hydraulic fluid levels and changing them according to the manufacturer's specifications can help prevent system degradation and costly repairs.

Another important tip is to routinely inspect hoses and fittings for any signs of wear or leaks. Damaged hoses can lead to significant fluid loss and even operational failure. It's advisable to replace any worn components before they lead to major issues. Regular monitoring of hydraulic pressure can also help identify any deviations that could indicate a problem, allowing for timely intervention.

Lastly, keeping the hydraulic system clean is paramount. Contaminants in the fluid can cause damage and reduce performance over time. Using proper filtration systems and regularly checking filters can help maintain the integrity of the hydraulic fluid, ensuring that all components function optimally. By following these tips, you can enhance the reliability and longevity of hydraulic systems in your everyday machines.

Related Posts

-

Innovative Solutions for Fluid Power Hydraulics Efficiency

-

Understanding the Importance of Hydraulic Components in Modern Machinery

-

Unveiling the Future of Fluid Power Hydraulics in Sustainable Engineering

-

10 Essential Tips for Mastering Pneumatic and Hydraulic Systems

-

Pneumatic Hydraulics Versus Traditional Hydraulics A Comprehensive Comparison of Efficiency and Performance

-

7 Compelling Reasons to Choose Fluid Power Hydraulics for Your Industrial Needs

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us