Unveiling the Future of Fluid Power Hydraulics in Sustainable Engineering

In the realm of sustainable engineering, the role of fluid power hydraulics is becoming increasingly pivotal as industries seek effective solutions to enhance efficiency and reduce environmental impact. Reports from the International Fluid Power Association (IFPA) highlight that the global fluid power market is projected to reach $65 billion by 2026, driven by advancements in technology and the rising demand for energy-efficient systems. As organizations pivot towards sustainable practices, fluid power hydraulics offers innovative avenues for implementing renewable energy sources and optimizing resource utilization.

The integration of digital technologies within hydraulic systems not only improves operational performance but also addresses the pressing challenges of greenhouse gas emissions and energy consumption. This paradigm shift presents an opportunity for engineers to reimagine hydraulic applications, ensuring they align with the principles of sustainability while maintaining high productivity levels.

Exploring Innovative Hydraulic Solutions for Sustainable Engineering Applications

In recent years, the emphasis on sustainability has propelled the exploration of innovative hydraulic solutions within the realm of fluid power. These advancements are crucial for reducing environmental impacts while maintaining operational efficiency in various engineering applications. By integrating cutting-edge technology with traditional hydraulic systems, engineers are creating more eco-friendly alternatives that optimize energy use and minimize waste.

One notable trend is the development of bio-hydraulic fluids that not only offer the same performance levels as conventional oils but also ensure a reduced ecological footprint. Additionally, advancements in hydraulic control systems are making it possible to enhance the precision and responsiveness of machinery, leading to improved energy efficiency. These innovations not only support sustainable engineering goals but also provide a pathway toward more resilient and adaptable hydraulic systems in future applications. As industries continue to prioritize sustainability, the role of fluid power hydraulics will undoubtedly evolve, becoming a cornerstone of responsible engineering practices.

Integrating Digital Technologies in Fluid Power Systems for Enhanced Efficiency

The integration of digital technologies into fluid power systems is fast becoming a cornerstone of sustainable engineering practices. Advanced sensors, IoT connectivity, and real-time data analytics are not only driving operational efficiency but are also significantly reducing energy consumption. According to the International Fluid Power Society, adopting smart technologies can enhance system performance by up to 30%, translating into substantial cost savings and a smaller environmental footprint.

Tips: To maximize the efficiency of fluid power systems, consider implementing predictive maintenance strategies. Utilizing data analytics can help predict failures before they occur, reducing downtime and maintenance costs. Additionally, embracing energy-efficient components—like variable-speed pumps—can lead to an average of 15-20% reduction in energy use.

Moreover, integrating machine learning algorithms enables fluid power systems to adapt dynamically to varying loads and operational conditions. A report from the National Fluid Power Association indicates that utilizing such technologies can result in performance improvements exceeding 25%. This transformative approach not only boosts efficiency but also paves the way for more sustainable engineering solutions that align with global energy goals.

Tips: Regularly review system performance data to identify optimization opportunities. Small adjustments based on data insights can yield significant enhancements to fluid power system efficiency.

Tips for Implementing Eco-Friendly Practices in Hydraulic Design and Operation

In the realm of sustainable engineering, hydraulic systems play a pivotal role, particularly when it comes to eco-friendly practices. One essential approach to enhancing efficiency in fluid power hydraulics is the implementation of energy-efficient components. According to the International Fluid Power Society, adopting variable-speed drives and high-efficiency pumps can reduce energy consumption by up to 30%. Such innovations not only decrease operational costs but also minimize the carbon footprint of hydraulic systems.

Another vital strategy is the adoption of biodegradable hydraulic fluids, which can significantly reduce environmental impact. A study conducted by the National Renewable Energy Laboratory found that transitioning to bio-based fluids can decrease toxicity levels and enhance the biodegradability of hydraulic systems. Additionally, regular maintenance and leak detection protocols are critical in preventing contamination and ensuring optimal performance. Incorporating these eco-friendly practices into hydraulic design and operation can drive substantial progress toward sustainability goals, ultimately fostering a greener future for the industry.

Future Trends in Fluid Power: Harnessing Renewable Energy Sources

The future of fluid power hydraulics in sustainable engineering is intricately tied to the integration of renewable energy sources. As the global demand for clean energy continues to rise, the fluid power industry is adapting to harness these resources effectively. Innovations in hydraulic systems enable better utilization of solar, wind, and other renewable energies, which can drive sustainable practices across various sectors. This shift not only promotes energy efficiency but also supports the transition towards a greener economy.

The future of fluid power hydraulics in sustainable engineering is intricately tied to the integration of renewable energy sources. As the global demand for clean energy continues to rise, the fluid power industry is adapting to harness these resources effectively. Innovations in hydraulic systems enable better utilization of solar, wind, and other renewable energies, which can drive sustainable practices across various sectors. This shift not only promotes energy efficiency but also supports the transition towards a greener economy.

Tips: To stay ahead in this evolving field, businesses should explore partnerships with renewable energy providers and invest in R&D for developing hybrid hydraulic systems. Additionally, companies can benefit from participating in industry forums that focus on sustainable practices, creating networking opportunities where they can learn from leading experts.

As the landscape of energy generation and consumption shifts, understanding the implications of these developments on hydraulic technologies is crucial. The rise of rural data centers, driven by enhanced computing needs and innovative cooling solutions, exemplifies how energy constraints can lead to efficiency breakthroughs. Adopting a holistic approach that encompasses water and climate considerations will be essential for unlocking new opportunities in sustainable fluid power applications.

Maximizing Performance: Advanced Control Techniques for Sustainable Hydraulics

In the quest for sustainable engineering, the role of fluid power hydraulics has never been more critical. Advanced control techniques have emerged as a key driver for maximizing performance in hydraulic systems, making them not only more efficient but also environmentally friendly. According to a report by the International Hydraulic Association, the integration of sophisticated control algorithms can reduce energy consumption in hydraulic systems by up to 30%. This reduction is crucial as industries worldwide strive to meet stricter energy regulations and reduce their carbon footprints.

Moreover, the application of real-time monitoring and predictive maintenance has transformed the landscape of hydraulic operations. Utilizing data analytics, operators can optimize system performance and preemptively address potential failures, thus minimizing downtime. The Hydraulic Systems Research Group has documented that the implementation of these advanced control techniques can enhance machinery longevity by approximately 25%, significantly lowering operational costs. As sustainable engineering practices gain momentum, these innovations underscore the pivotal role of fluid power hydraulics in creating a more efficient and responsible industrial ecosystem.

Unveiling the Future of Fluid Power Hydraulics in Sustainable Engineering - Maximizing Performance: Advanced Control Techniques for Sustainable Hydraulics

| Control Technique | Efficiency Improvement (%) | Energy Consumption (kWh/m³) | Carbon Footprint Reduction (kg CO₂/m³) | Application Area |

|---|---|---|---|---|

| PID Control | 15% | 0.5 | 0.10 | Manufacturing |

| Fuzzy Logic Control | 20% | 0.4 | 0.15 | Construction |

| Adaptive Control | 25% | 0.3 | 0.20 | Agriculture |

| Model Predictive Control | 30% | 0.25 | 0.25 | Logistics |

Related Posts

-

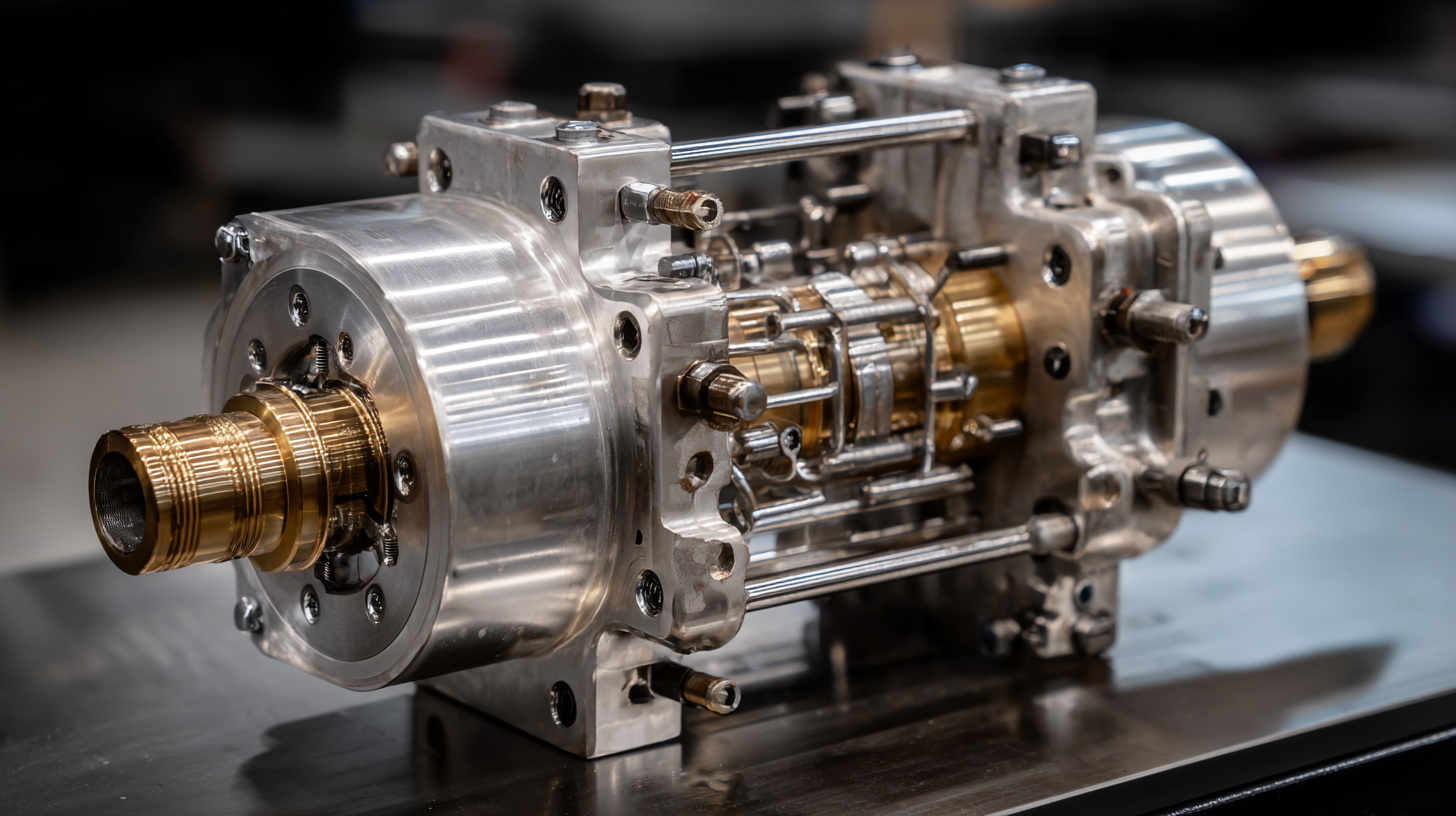

Understanding the Importance of Hydraulic Components in Modern Machinery

-

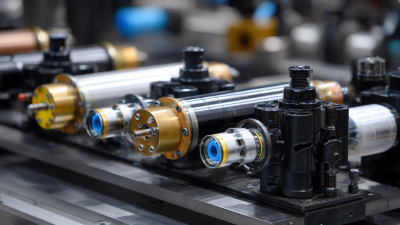

Innovative Solutions for Fluid Power Hydraulics Efficiency

-

Pneumatic Hydraulics Versus Traditional Hydraulics A Comprehensive Comparison of Efficiency and Performance

-

7 Compelling Reasons to Choose Fluid Power Hydraulics for Your Industrial Needs

-

How to Optimize Your Operations with Innovative Hydraulic Solutions

-

Understanding Common Issues with Hydraulic Pumps and Motors in Industrial Applications

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us