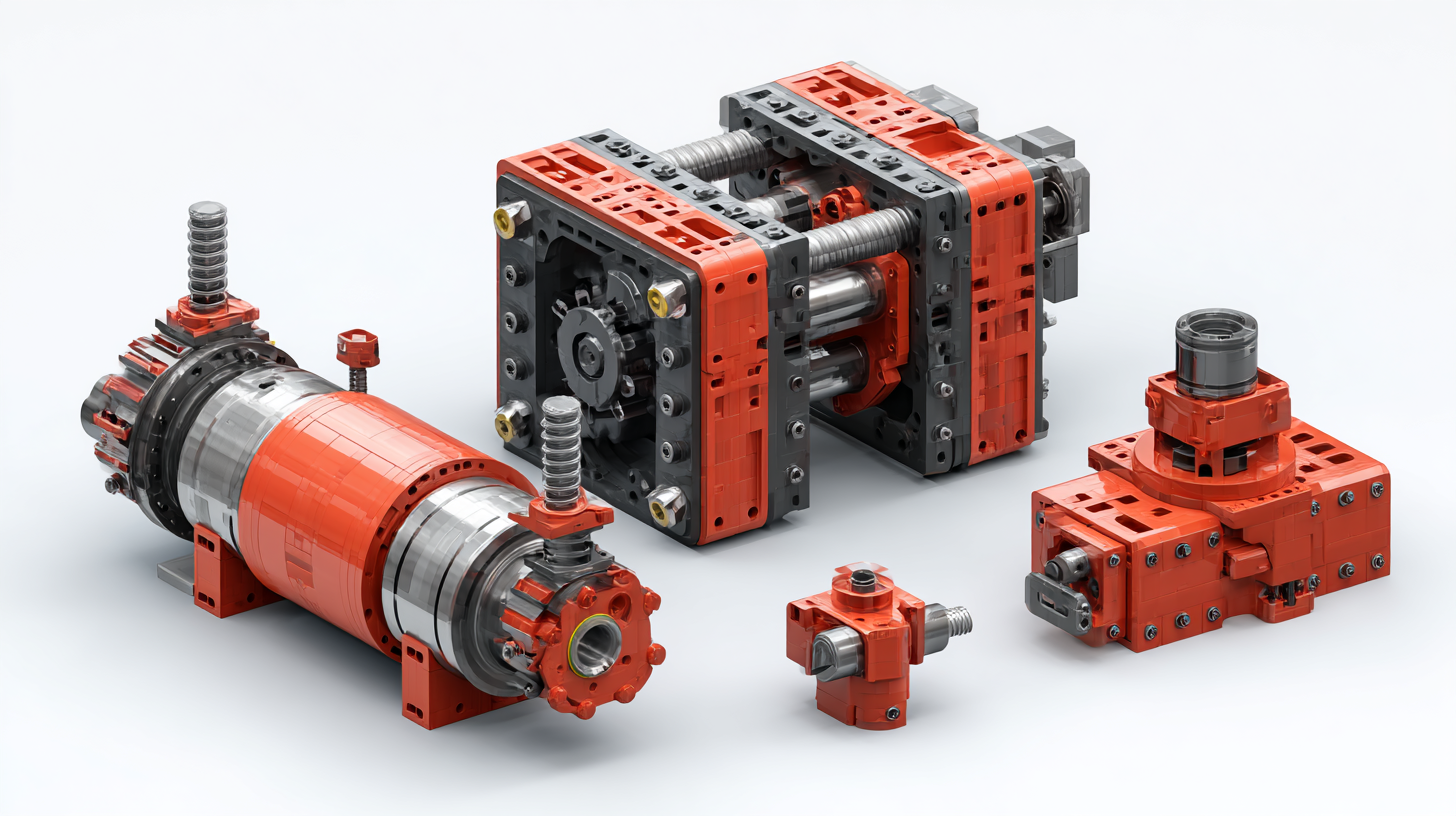

Unlocking the Future of Machinery: Innovative Trends in Hydraulic Parts for Enhanced Efficiency

The future of machinery hinges on the continuous evolution of hydraulic parts, which are pivotal in optimizing operational efficiency across various industries. Recent industry reports indicate that the global hydraulic components market is projected to reach approximately $50 billion by 2025, driven by increased demand for automated machinery and advanced construction equipment.

Innovations in hydraulic parts, such as smart sensors and integrated IoT solutions, not only enhance performance but also reduce energy consumption, significantly impacting overall productivity. With hydraulic systems accounting for nearly 30% of the energy used in industrial machinery, the push towards more efficient hydraulic components is not just a trend but a necessity for businesses aiming to stay competitive.

As organizations seek to maximize their operational capabilities, understanding and leveraging these innovative trends in hydraulic parts will be essential for unlocking greater efficiency and sustainability in machinery operations.

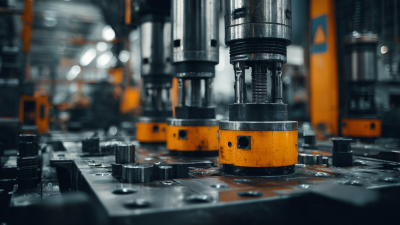

Transforming Hydraulic Efficiency: The Role of IoT in Machinery Optimization

The integration of the Internet of Things (IoT) into hydraulic systems represents a significant leap towards optimizing machinery efficiency. By equipping hydraulic parts with smart sensors, manufacturers can monitor real-time data such as pressure levels, flow rates, and temperature variations. This wealth of information not only enables predictive maintenance but also facilitates immediate adjustments to operational parameters, thereby ensuring machines operate at peak efficiency and reducing downtime.

Moreover, IoT-driven analytics provide deeper insights into machinery performance, allowing for continuous improvement in system design and operation. For instance, data collected over time can reveal patterns that highlight inefficiencies or unusual wear in hydraulic components. Armed with this knowledge, engineers can make informed decisions on upgrades or modifications, resulting in enhanced reliability and productivity. In this era of smart manufacturing, the convergence of IoT technology and hydraulic systems marks a new chapter in the quest for energy-efficient and high-performance machinery.

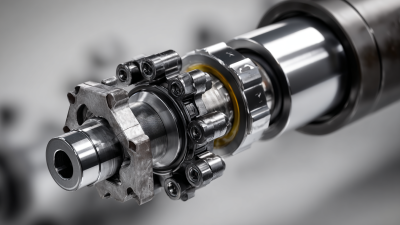

Industry Insights: Impact of AI on Predictive Maintenance for Hydraulic Parts

The integration of artificial intelligence (AI) into predictive maintenance is reshaping the hydraulic parts industry, paving the way for enhanced operational efficiency and reduced downtime. Recent reports indicate that the predictive maintenance market is expected to grow from $3.5 billion in 2020 to $12.3 billion by 2025, reflecting a compound annual growth rate (CAGR) of 27.4%. This rapid growth underscores the increasing adoption of AI technologies that enable manufacturers to foresee maintenance needs before failures occur, thereby minimizing unexpected breakdowns in hydraulic machinery.

One notable advancement is the use of machine learning algorithms that analyze operational data from hydraulic systems. As reported by McKinsey & Company, companies employing AI-driven predictive maintenance strategies can achieve a 20% reduction in maintenance costs and a 25% increase in equipment availability. By harnessing real-time data analytics, businesses can make informed decisions about when to service hydraulic parts, optimizing their lifespan and improving overall efficiency. The impact of AI in this domain signifies a transformative shift towards more intelligent machinery management, ultimately supporting sustainable industrial practices.

Unlocking the Future of Machinery: Enhancing Efficiency in Hydraulic Parts

This chart illustrates the growing efficiency of hydraulic parts from 2018 to 2023. The data suggests a positive trend in efficiency improvements, attributed to advancements in technology and the integration of AI in predictive maintenance strategies.

Sustainable Innovations: The Rise of Eco-Friendly Hydraulic Fluids and Their Benefits

The adoption of eco-friendly hydraulic fluids is revolutionizing the machinery industry, addressing the critical need for sustainability in hydraulic systems. Traditional hydraulic fluids often contain harmful additives that can compromise environmental safety. In contrast, the rise of bio-based and non-toxic hydraulic fluids offers a promising alternative, significantly reducing the ecological impact of hydraulic machinery. These innovative fluids are not only safer for the environment but also exhibit comparable performance metrics, including lubrication, temperature resistance, and service life, making them a viable choice for modern machinery.

Moreover, the integration of eco-friendly hydraulic fluids contributes to enhanced efficiency in operations. With lower toxicity and better biodegradability, these fluids minimize the risks associated with leaks and spills, thus improving workplace safety and reducing cleanup costs. Companies adopting sustainable hydraulic fluids can also benefit from improved public perception and compliance with increasingly stringent regulatory frameworks. As industries pivot towards greener practices, the shift to eco-friendly hydraulic solutions marks a significant step towards a more sustainable and efficient future in machinery.

Unlocking the Future of Machinery: Innovative Trends in Hydraulic Parts for Enhanced Efficiency

| Dimension | Description | Innovative Trend | Benefits |

|---|---|---|---|

| Hydraulic Efficiency | Measures how effectively hydraulic systems convert energy | High-Performance Hydraulic Parts | Improved machine performance and reduced energy wastage |

| Eco-Friendly Fluids | Biodegradable fluids that minimize environmental impact | Sustainable Hydraulic Fluids | Reduced pollution and enhanced sustainability in operations |

| Maintenance Cost | Total cost incurred from regular maintenance of hydraulic systems | Smart Monitoring Technologies | Lower long-term maintenance costs and downtime |

| Energy Consumption | Amount of energy used in operating hydraulic machinery | Energy-Efficient Design | Significant reduction in operational costs |

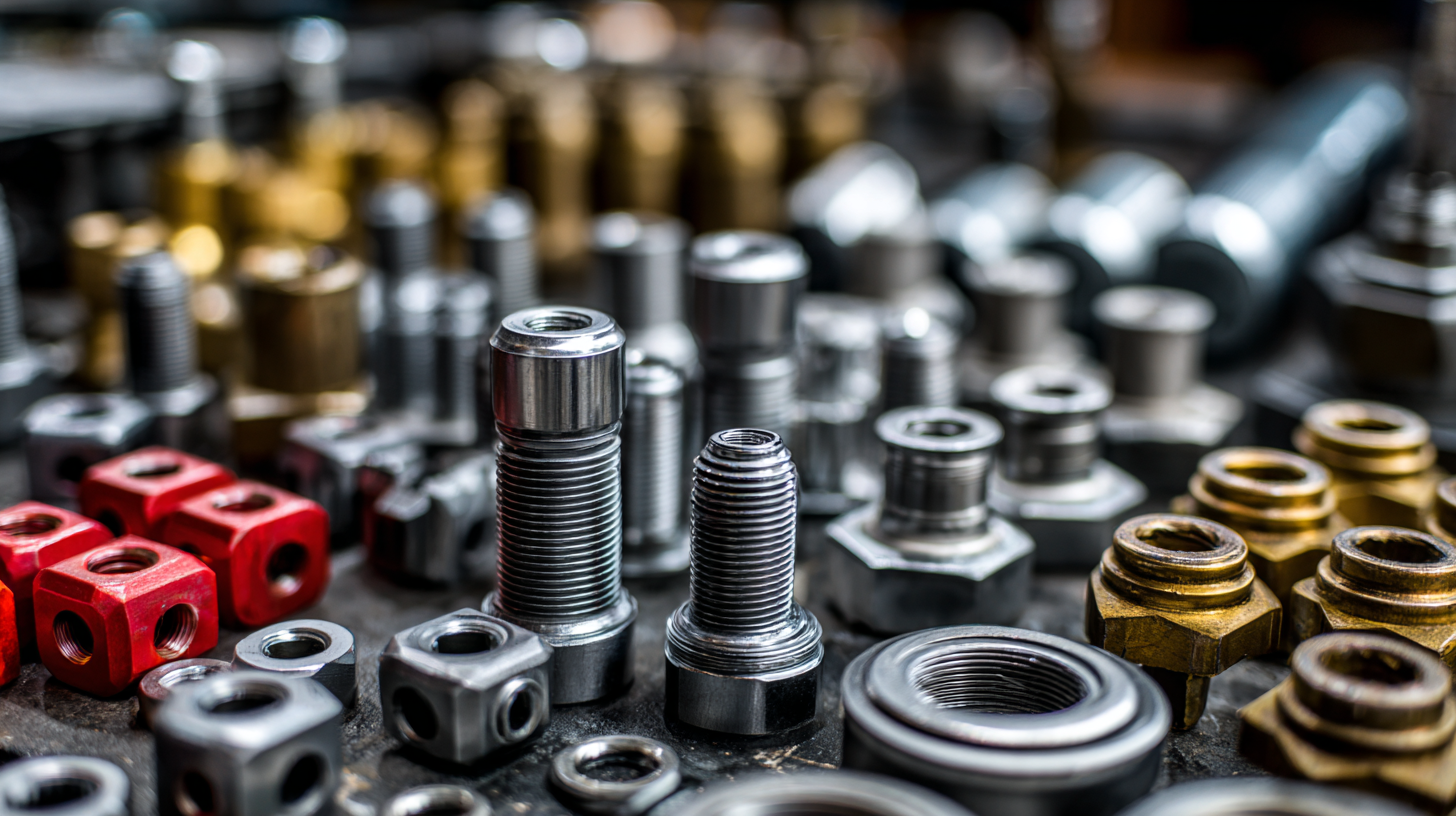

| Lifetime | Duration hydraulic parts function effectively before replacement | Durable Materials | Extended lifespan and lower replacement costs |

Market Trends: Growth Projections for Smart Hydraulic Technologies by 2025

The market for smart hydraulic technologies is poised for significant growth, with projections indicating a rise from $167.1 billion in 2025 to an impressive $240.3 billion by 2032. This surge is driven by the increasing demand for efficient and eco-friendly hydraulic systems in various sectors, including automotive and construction. As industries continue to innovate, the focus on enhancing the efficiency and sustainability of hydraulic components becomes paramount.

In particular, the automotive sector is witnessing a shift toward electric hydraulic power steering systems, projected to reach a market size of $9.2 billion by 2024, with a compound annual growth rate (CAGR) of 7.3% from 2025 to 2034. This trend reflects a broader move towards energy-saving technologies, aligning with global efforts to reduce carbon footprints.

Tips: Embracing smart hydraulic solutions not only enhances operational efficiency but also positions companies favorably in a competitive landscape. As technology evolves, staying updated on market trends and innovations will empower businesses to capitalize on emerging opportunities in hydraulic systems.

Data-Driven Design: Leveraging Big Data for Enhanced Hydraulic Performance Metrics

The evolution of hydraulic parts is poised to redefine machinery efficiency through innovative design informed by big data. By analyzing vast datasets, manufacturers can gain deep insights into the performance and wear patterns of hydraulic components. This data-driven approach allows for predictive maintenance, minimizing downtime and ensuring systems operate at peak performance. For example, companies can utilize real-time data analytics to adjust hydraulic fluid compositions or optimize valve configurations, enhancing overall system responsiveness and reliability.

Moreover, leveraging big data in design not only improves existing equipment but also guides the development of next-generation hydraulic components. Design engineers can simulate a variety of operating conditions and load scenarios, identifying potential failure points before they occur. This proactive methodology enables the creation of highly resilient parts, tailored to specific industry needs, whether in construction, agriculture, or manufacturing. The future of hydraulic technology lies in the synergy between data analytics and innovative engineering, unlocking unprecedented performance metrics that drive efficiency and strengthen operational capabilities.

Related Posts

-

Unveiling Hydraulic Parts Innovations at the 138th Canton Fair 2025 in China

-

Top Strategies for Optimizing Hydraulic System Efficiency

-

Understanding the Key Components of Hydraulic Cylinder Parts

-

10 Best Hydraulic Cylinder Parts You Should Know

-

Why Understanding Pneumatic and Hydraulic Systems is Essential for Modern Industries

-

Understanding the Essential Role of Hydraulic Parts in Modern Machinery

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us