Ultimate Guide to Selecting the Right Hydraulic Hose Fittings for Your Project

In the ever-evolving landscape of industrial applications, the selection of hydraulic hose fittings is pivotal for ensuring optimal performance and safety. According to a recent report by the Hydraulic Institute, over 30% of equipment failures in hydraulic systems can be attributed to inappropriate fittings which lead to leaks and inefficiencies. As industries increasingly prioritize efficiency and sustainability, understanding how to select the right hydraulic hose fittings becomes imperative.

This guide will delve into essential tips and insights, helping professionals navigate the complexities of hydraulic systems to make informed decisions. Whether you are working on heavy machinery, mobile equipment, or manufacturing processes, the right hydraulic hose fittings can significantly impact system effectiveness, longevity, and overall project success.

Understanding Hydraulic Hose Fittings: Types, Standards, and Applications

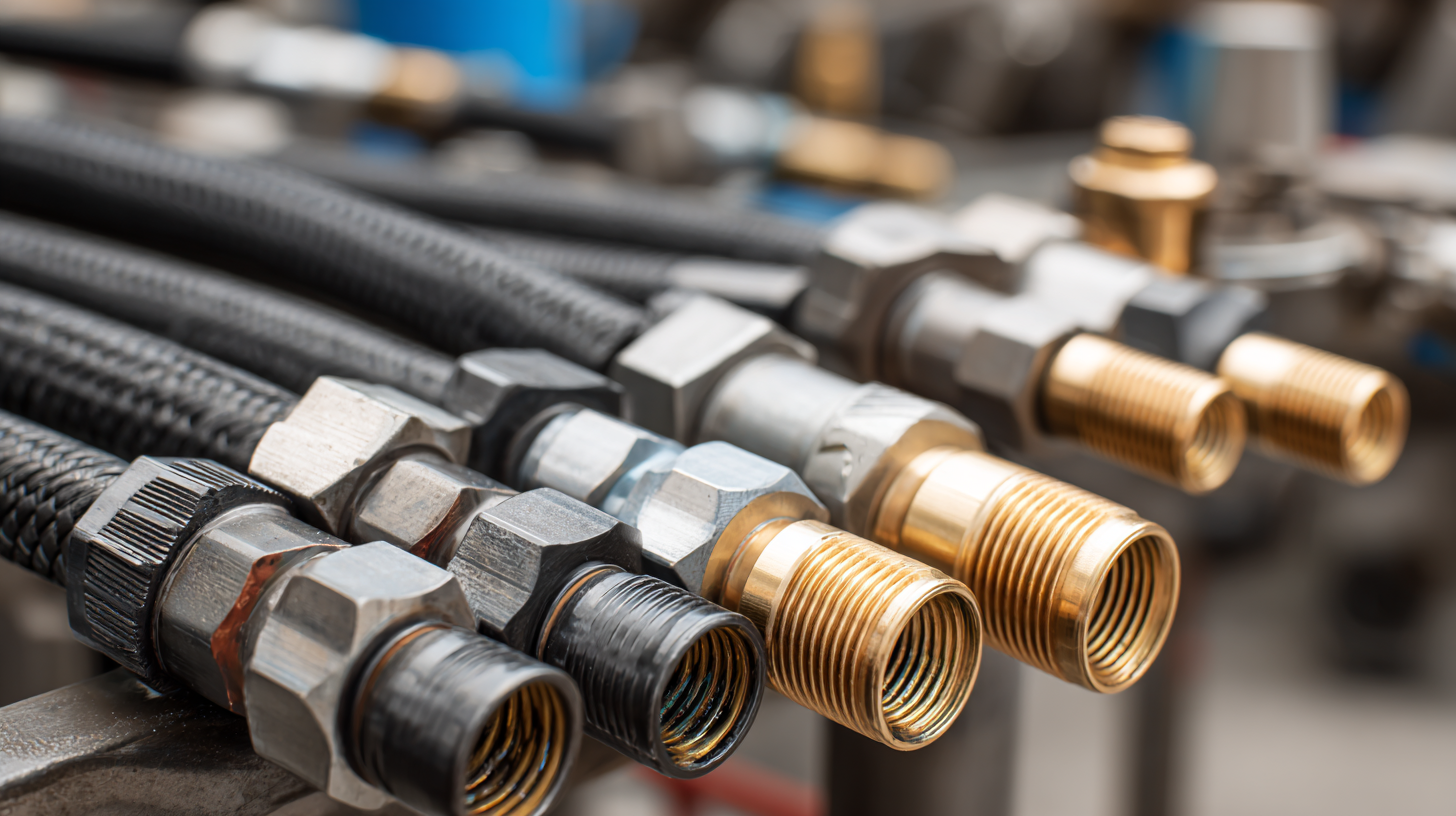

When it comes to hydraulic systems, selecting the right hose fittings is crucial for ensuring efficiency and safety. Hydraulic hose fittings come in various types, each designed for specific applications. Common types include swivel fittings, fixed fittings, and quick-connect fittings. Swivel fittings allow for rotational movement, minimizing stress on hoses, while fixed fittings provide a solid, leak-proof connection. Quick-connect fittings are designed for easy assembly and disassembly, making them perfect for applications requiring frequent changes. Understanding the different types and their applications will help you make informed decisions for your projects.

In addition to types, awareness of standards is essential when selecting hydraulic hose fittings. The industry has established several standards, including SAE (Society of Automotive Engineers) and ISO (International Organization for Standardization), which govern the design and performance requirements of these fittings. Adhering to these standards ensures compatibility and reliability within hydraulic systems. Moreover, knowing the various materials, such as stainless steel, brass, and aluminum, is vital, as it affects durability, corrosion resistance, and temperature tolerance. By grasping the types, standards, and materials of hydraulic hose fittings, you can optimize your hydraulic systems for specific project needs.

Ultimate Guide to Selecting the Right Hydraulic Hose Fittings for Your Project

| Fitting Type | Standard | Application | Pressure Rating | Material |

|---|---|---|---|---|

| NPT Fitting | SAE J514 | General purpose fluid transfer | Up to 3,000 PSI | Steel |

| BSP Fitting | ISO 7-1 | Hydraulic systems in Europe | Up to 8,000 PSI | Brass |

| JIC Fitting | SAE J514 | High pressure hydraulic systems | Up to 6,000 PSI | Steel |

| Flat Face Fitting | ISO 16028 | Machine tools and agricultural equipment | Up to 5,000 PSI | Aluminum |

| Cam Lock Fitting | ANSI B93.3 | Fluid transfer for agriculture and industrial use | Up to 200 PSI | Aluminum |

Key Factors to Consider When Selecting Hydraulic Hose Fittings for Optimal Performance

When selecting hydraulic hose fittings, several key factors significantly impact performance and reliability. First, understanding the operating pressure and fluid type is essential. According to a report by the International Fluid Power Society, nearly 30% of hydraulic system failures are attributed to improper fittings, often due to pressure miscalculations. Ensuring that the selected fittings are rated for the specific pressure requirements of your application can help prevent costly breakdowns.

Another critical consideration is the compatibility of materials. Hydraulic systems commonly utilize fittings made from various materials, including steel, stainless steel, and brass, each offering unique advantages. Research from the Hydraulic Institute indicates that using incompatible materials can lead to corrosion and leaks, which can compromise system integrity. Therefore, it is vital to assess the environmental conditions and select a fitting material that can withstand both the fluids used and external conditions to enhance durability and performance.

Lastly, proper sizing cannot be overlooked. Fittings must match the hose diameter and type for optimal flow and efficiency. The Engineering Toolbox highlights that improperly sized fittings can result in increased friction loss, reducing energy efficiency by up to 15%. Taking the time to accurately measure and select the right size will help ensure that your hydraulic system operates smoothly and effectively.

Industry Standards and Regulations for Hydraulic Hose Fittings You Need to Know

When selecting hydraulic hose fittings for your project, understanding the industry standards and regulations is crucial to ensure safety and efficiency. The American National Standards Institute (ANSI) and the Society of Automotive Engineers (SAE) provide detailed specifications for hydraulic fittings. For instance, SAE J514 outlines the requirements for hydraulic tube fittings, emphasizing the need for proper sealing and compatibility with various hydraulic fluids. Adhering to these standards not only reduces the risk of leaks but also enhances the longevity of the system.

Furthermore, the Occupational Safety and Health Administration (OSHA) sets forth regulations that demand compliance with specific pressure ratings and material properties for hydraulic equipment. A recent report from the International Organization for Standardization (ISO) indicated that nearly 30% of hydraulic hose failures result from improper fittings, highlighting the importance of selecting components that meet ISO 12151 standards. By ensuring your fittings align with these regulations, you can significantly mitigate potential hazards associated with hydraulic hose systems, thereby improving operational reliability and worker safety.

Top 5 Materials Used in Hydraulic Hose Fittings and Their Impact on Durability

When selecting hydraulic hose fittings, the material of the fittings plays a crucial role in determining their durability and performance. The top five materials commonly used in hydraulic hose fittings include steel, stainless steel, brass, aluminum, and plastic. According to a report by the Hydraulic Industry Manufacturers Association, about 80% of hydraulic fittings are made from steel due to its high tensile strength and resistance to wear and tear. This robustness makes steel an ideal choice for high-pressure applications, where fitting integrity is paramount.

Stainless steel, while more expensive, is often chosen for its corrosion resistance, making it vital for environments subject to moisture or chemicals. A study from the Fluid Power Journal indicates that stainless steel fittings can outperform their steel counterparts by up to 30% in corrosive conditions, significantly extending service life. Brass fittings, although less popular in high-pressure applications, are favored for their machinability and resistance to galling.

On the other hand, aluminum fittings are sought after in lightweight applications, offering a balance between strength and weight, especially in mobile machinery. Lastly, engineered plastics have started gaining traction for specific hydraulic applications due to their excellent chemical resistance and lightweight nature, providing solutions where traditional metals might fail. Understanding the implications of each material choice can lead to improved system reliability and cost-effectiveness.

Common Mistakes to Avoid When Choosing Hydraulic Hose Fittings for Your Projects

When selecting hydraulic hose fittings for your project, avoiding common mistakes can lead to significant improvements in performance and durability. One prevalent error is over-tightening fittings, which can create stress points and crack pipes, as noted by industry experts. Data from recent studies have indicated that improper installation is responsible for nearly 30% of hydraulic system failures, emphasizing the importance of making informed decisions regarding hose fittings.

Additionally, considering the environmental factors affecting your project is crucial. For example, with increasing instances of natural disasters such as earthquakes, more industries are turning to robust materials like ductile iron pipes. Adopting modern materials and technologies ensures that the selected hydraulic fittings can withstand pressure fluctuations and physical stresses, which is vital in areas prone to seismic activity. By understanding the unique requirements of your project and taking heed of the common pitfalls, you can enhance the reliability and safety of your hydraulic systems.

Related Posts

-

Understanding Common Issues with Hydraulic Pumps and Motors in Industrial Applications

-

5 Essential Tips for Choosing the Right Hydraulic Pump Motor for Your Industrial Needs

-

Understanding the Key Components of Hydraulic Cylinder Parts

-

Essential Pneumatic Hydraulic Maintenance Checklist for Optimal Performance

-

Pneumatic Hydraulics Versus Traditional Hydraulics A Comprehensive Comparison of Efficiency and Performance

-

How to Choose the Right Gas Powered Hydraulic Pump for Your Needs

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us