Understanding the Importance of Hydraulic Components in Modern Machinery

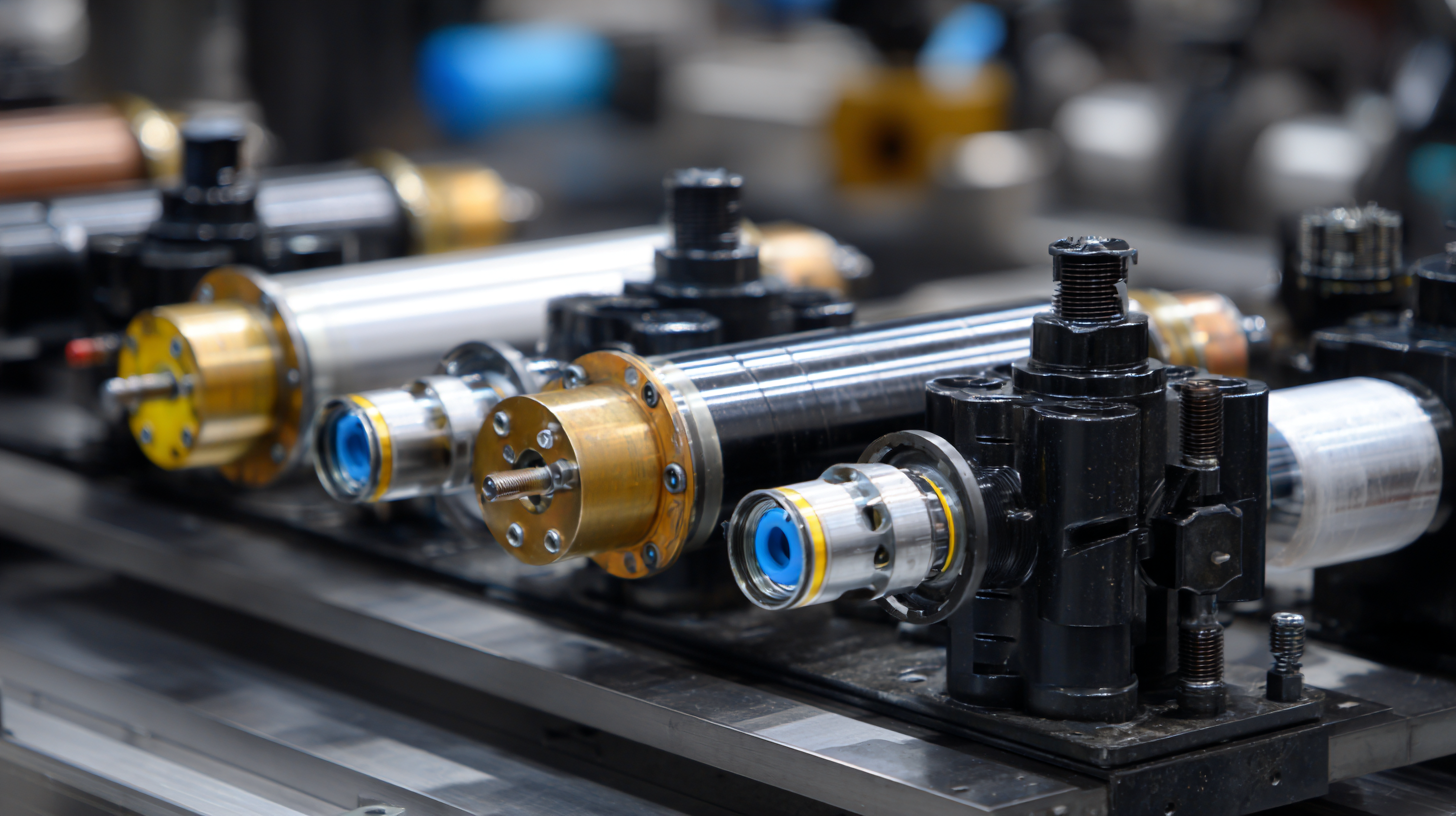

In the realm of modern machinery, the significance of hydraulic components cannot be overstated. These crucial elements, which include pumps, cylinders, valves, and hoses, play an integral role in ensuring the efficiency and functionality of various industrial applications. The dynamic nature of hydraulic systems enables them to convert and transmit energy through fluid power, allowing machines to perform complex tasks with remarkable precision. As industries continue to evolve, the demand for high-performance hydraulic components has surged, driving innovation and advancements in hydraulic technology. Understanding the intrinsic value of these components is essential for engineers and operators alike, as it directly influences the productivity, reliability, and longevity of machinery. This exploration of hydraulic components highlights their foundational importance in enhancing operational capabilities across diverse sectors, ultimately making them indispensable to the modern industrial landscape.

In the realm of modern machinery, the significance of hydraulic components cannot be overstated. These crucial elements, which include pumps, cylinders, valves, and hoses, play an integral role in ensuring the efficiency and functionality of various industrial applications. The dynamic nature of hydraulic systems enables them to convert and transmit energy through fluid power, allowing machines to perform complex tasks with remarkable precision. As industries continue to evolve, the demand for high-performance hydraulic components has surged, driving innovation and advancements in hydraulic technology. Understanding the intrinsic value of these components is essential for engineers and operators alike, as it directly influences the productivity, reliability, and longevity of machinery. This exploration of hydraulic components highlights their foundational importance in enhancing operational capabilities across diverse sectors, ultimately making them indispensable to the modern industrial landscape.

The Role of Hydraulic Components in Enhancing Machinery Efficiency

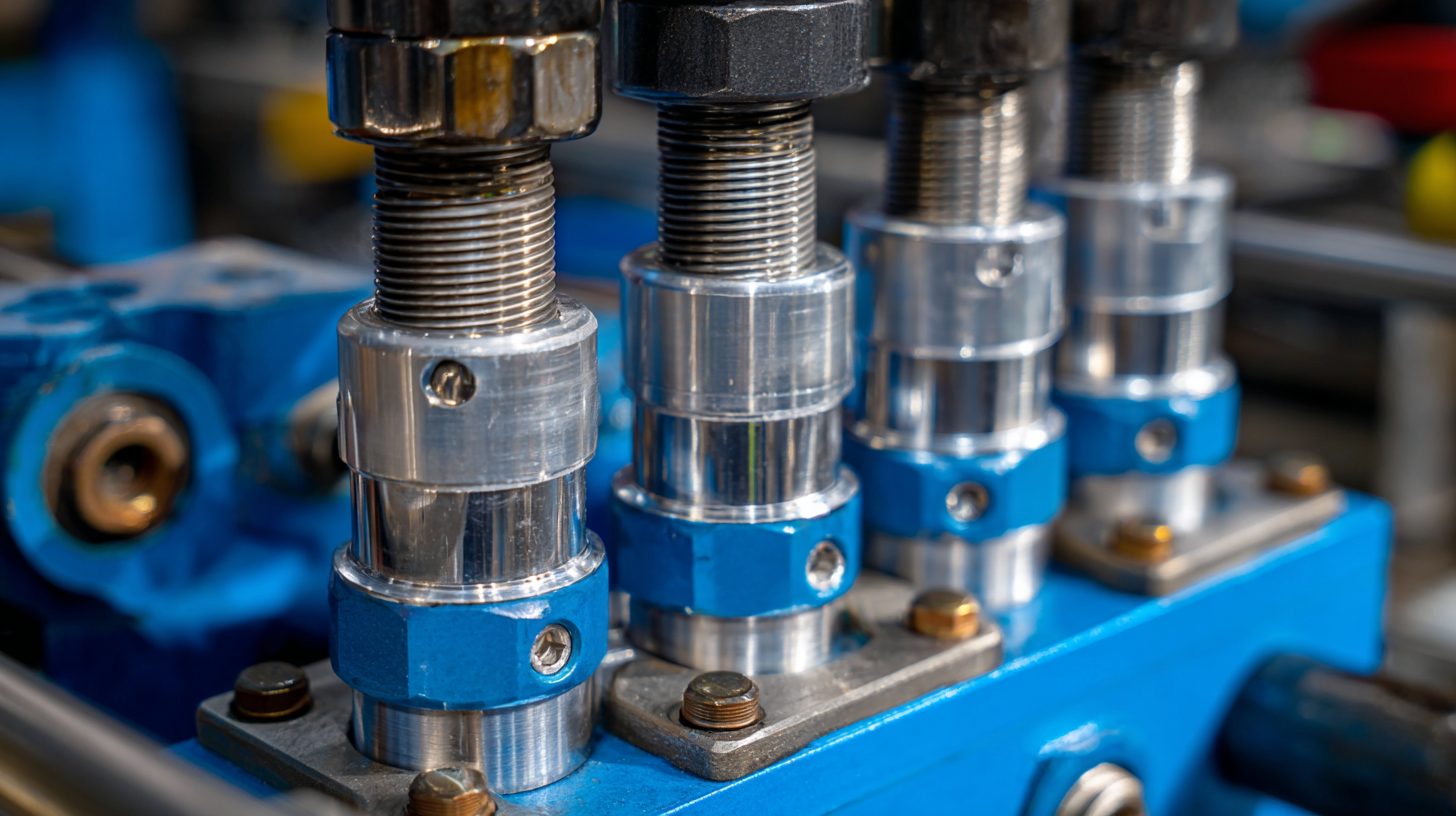

Hydraulic components play a critical role in enhancing the efficiency of modern machinery by providing the necessary force and precision required for various applications. These components, including pumps, cylinders, and valves, work together to convert hydraulic energy into mechanical work, enabling machines to perform with remarkable strength and accuracy. By utilizing incompressible fluids to transmit power, hydraulic systems can achieve higher force outputs than their mechanical counterparts while maintaining a compact design, making them ideal for heavy-duty industrial tasks.

Moreover, the adaptability of hydraulic components significantly contributes to the dynamic performance of machinery. By adjusting the flow rate and pressure of hydraulic fluid, operators can fine-tune the functionality of their machines to meet specific operational demands. This flexibility allows for smoother operations and less wear and tear on machinery, thereby reducing downtime and maintenance costs. As industries continue to evolve, the integration of advanced hydraulic technologies will further enhance machinery efficiency, leading to increased productivity and sustainability in various sectors.

Understanding the Importance of Hydraulic Components in Modern Machinery

This bar chart illustrates the impact of various hydraulic components on the overall efficiency of modern machinery. Each component plays a critical role in optimizing performance and ensuring reliable functionality.

Types of Hydraulic Components and Their Functions in Modern Equipment

Hydraulic components play a crucial role in the functionality of modern machinery, ensuring efficient operation across various industries. Key hydraulic components include pumps, valves, actuators, and fluid reservoirs. Each of these components works synergistically to control and direct the flow of hydraulic fluids, enabling remarkable lifting, pushing, and pulling capabilities. According to a report from the International Organization for Standardization (ISO), the global market for hydraulic components is expected to reach approximately $43 billion by 2025, underscoring the increasing reliance on these technologies in industrial applications.

Pumps are fundamental to any hydraulic system, converting mechanical energy into hydraulic energy, and determine the efficiency and power of the entire apparatus. Valves regulate fluid flow and pressure, providing precise control over hydraulic operations. Actuators, responsible for translating hydraulic energy into mechanical motion, are critical for tasks ranging from lifting heavy loads to operating advanced manufacturing machines. The latest data from the Fluid Power Journal highlights that hydraulic actuators have become indispensable in automation processes, responsible for up to 85% of movement in various robotic systems, which signifies their growing importance in modern equipment design and functionality.

Key Benefits of Using Hydraulic Systems in Industrial Applications

Hydraulic systems play a crucial role in modern industrial applications, offering several key benefits that enhance operational efficiency and effectiveness. One of the primary advantages of using hydraulic components is their ability to transmit power with impressive precision and control. This allows machinery to perform complex tasks with minimal effort, making it ideal for applications in construction, manufacturing, and automotive industries. With hydraulic systems, operators can manage heavy loads and intricate movements smoothly, resulting in increased productivity and reduced risk of mechanical failure.

Another significant benefit of hydraulic systems lies in their versatility and scalability. Unlike traditional mechanical systems, hydraulic components can be easily adapted to various machine configurations and requirements. This flexibility enables manufacturers to design equipment that meets specific performance criteria without needing extensive mechanical alterations. Additionally, hydraulic systems are well-suited for applications that require high force in a compact design, allowing for smaller machinery footprints without compromising power. Thus, the integration of hydraulic components in modern machinery not only optimizes performance but also contributes to overall operational efficiency in diverse industrial environments.

Maintenance Practices for Ensuring Longevity of Hydraulic Components

Hydraulic components play a crucial role in the efficiency and performance of modern machinery, directly impacting productivity and operational costs. To ensure their longevity, implementing routine maintenance practices is essential. According to a report by the International Fluid Power Society (IFPS), nearly 70% of hydraulic system failures are attributed to poor maintenance. Regular inspections and timely replacements of filters can help prevent contamination, which is a leading cause of premature wear in hydraulic systems.

To protect your hydraulic components effectively, here are some maintenance tips: First, establish a routine schedule for fluid levels and quality checks. Maintaining proper fluid conditions is critical; as per the National Fluid Power Association (NFPA), clean hydraulic fluids can reduce wear significantly by up to 50%. Second, always monitor for leaks and pressure drops. Ignoring these signs can lead to catastrophic failures and costly downtime. Lastly, invest in comprehensive training for your maintenance staff. A well-informed team can quickly identify and address potential issues before they escalate, ensuring optimal performance of your hydraulic systems.

Understanding the Importance of Hydraulic Components in Modern Machinery

Maintenance Practices for Ensuring Longevity of Hydraulic Components

| Component Type | Common Issues | Maintenance Practices | Expected Lifespan (Years) |

|---|---|---|---|

| Hydraulic Pumps | Cavitation, wear and tear | Regular fluid checks, clean filters | 5-10 |

| Hydraulic Cylinders | Seal failure, leakage | Inspect seals, monitor rod condition | 7-12 |

| Hydraulic Hoses | Cracking, bursting | Visual inspections, replace every 5 years | 5-10 |

| Hydraulic Valves | Sticking, leakage | Regular cleaning, testing for responsiveness | 6-11 |

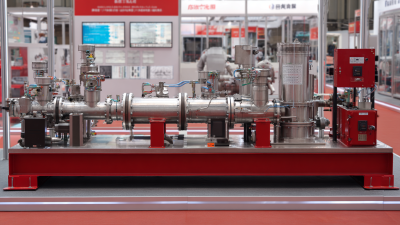

Future Trends and Innovations in Hydraulic Technology for Machinery

The hydraulic components play a crucial role in modern machinery, serving as the backbone for a wide range of industrial applications. As technology continues to evolve, the future of hydraulic systems is poised for significant advancements. One of the most notable trends is the increasing integration of smart technology into hydraulic systems, allowing for enhanced monitoring and control. These innovations aim to improve efficiency, reduce energy consumption, and minimize maintenance costs, making machinery more sustainable and cost-effective.

The global hydraulic breaker market reflects this growth trend, with projections indicating a market size of approximately $157.49 million by 2025 and an expected rise to $228.578 million by 2033. This upward trajectory highlights the rising demand for hydraulic technology and its innovative applications across multiple sectors, including construction, mining, and manufacturing. As industries increasingly adopt more sophisticated hydraulic systems, the emphasis on developing more efficient and reliable hydraulic components will become paramount, paving the way for a more robust and efficient machinery landscape in the coming years.

Related Posts

-

Essential Pneumatic Hydraulic Maintenance Checklist for Optimal Performance

-

Innovative Solutions for Fluid Power Hydraulics Efficiency

-

How to Optimize Your Operations with Innovative Hydraulic Solutions

-

Pneumatic Hydraulics Versus Traditional Hydraulics A Comprehensive Comparison of Efficiency and Performance

-

7 Compelling Reasons to Choose Fluid Power Hydraulics for Your Industrial Needs

-

Revolutionizing Hydraulic Systems Trends and Insights at the 138th China Import and Export Fair 2025

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us