Top 5 Hydraulic Cylinder Parts That Boost Performance and Efficiency in Machinery

In the competitive landscape of machinery performance and efficiency, the role of hydraulic cylinder parts cannot be overstated. According to a recent report by the International Fluid Power Society (IFPS), optimizing the components of hydraulic systems can improve operational efficiency by over 20%. This statistic highlights the critical importance of selecting the right hydraulic cylinder parts for enhanced machinery performance.

Industry expert Dr. Richard Thorne, a leading authority on hydraulic engineering, asserts, "The meticulous selection and maintenance of hydraulic cylinder parts are essential for maximizing the lifespan and efficiency of machinery." His insights underscore the necessity for manufacturers to focus on critical components that can significantly impact overall system functionality.

In this article, we will explore the top five hydraulic cylinder parts that are instrumental in driving performance improvements and operational efficiency. By examining these key components, we aim to provide insights that can help machinery operators and manufacturers make informed decisions to boost their operations.

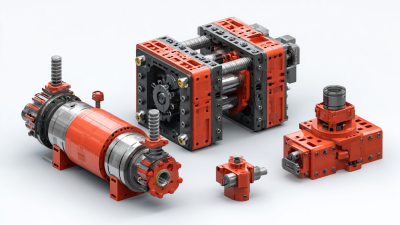

Top 5 Features of High-Performance Hydraulic Cylinders for Optimal Efficiency

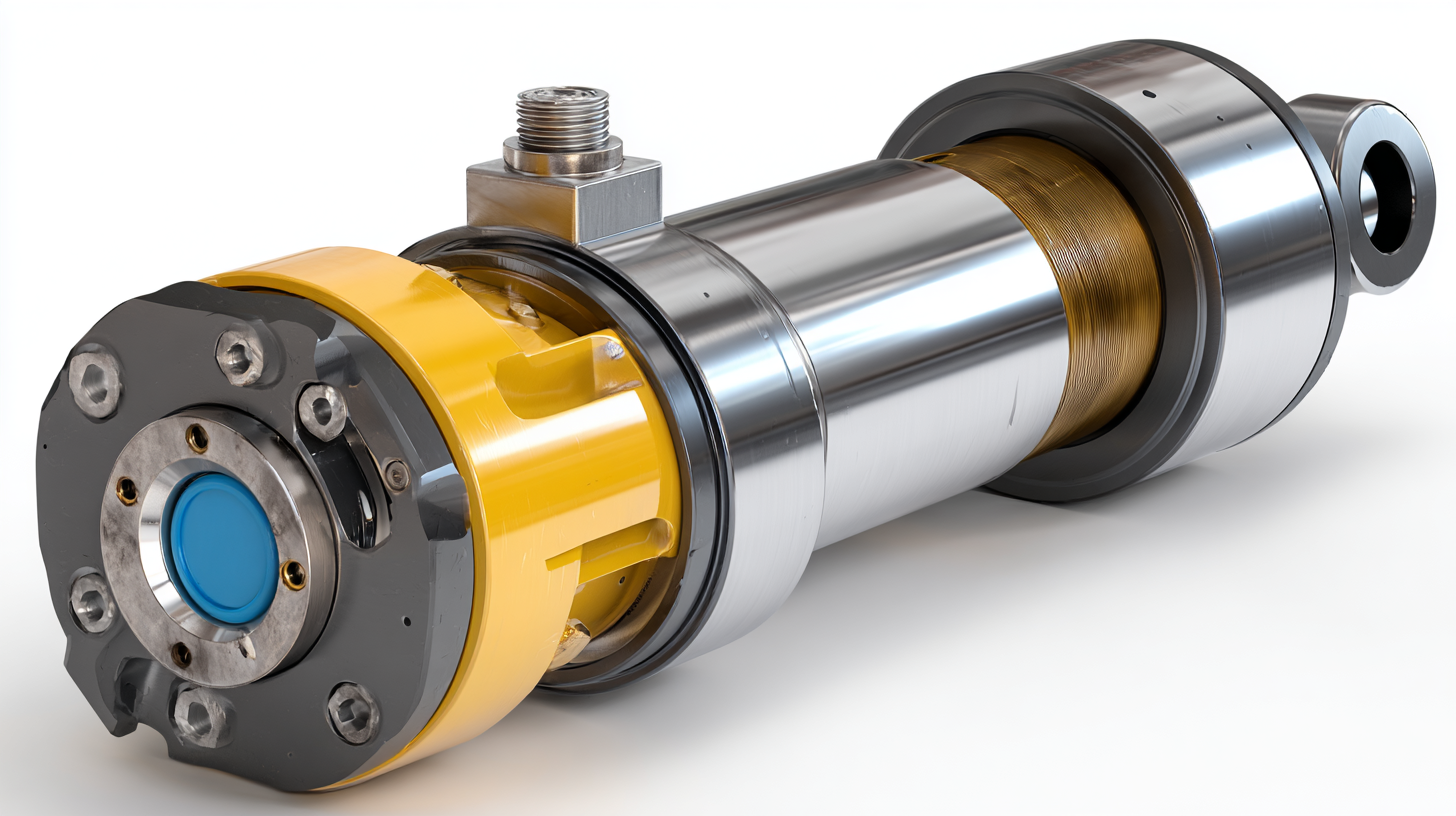

High-performance hydraulic cylinders are essential for enhancing the efficiency of various machinery applications. One key feature is their advanced sealing technology, which minimizes fluid leakage and maximizes operational reliability. High-quality seals not only contribute to improved performance but also extend the lifespan of the cylinder by reducing wear and tear. This results in a smoother operation and less frequent maintenance, ultimately lowering costs and downtime.

Another critical characteristic is the use of high-strength materials. Hydraulic cylinders constructed from durable alloys can withstand extreme pressure and temperature fluctuations, ensuring consistent performance under demanding conditions. Additionally, precision engineering in the manufacturing process plays a significant role in maintaining tight tolerances, which enhances both response time and overall efficiency.

These features collectively ensure that hydraulic cylinders deliver superior power and responsiveness, making them indispensable in industries where performance is paramount.

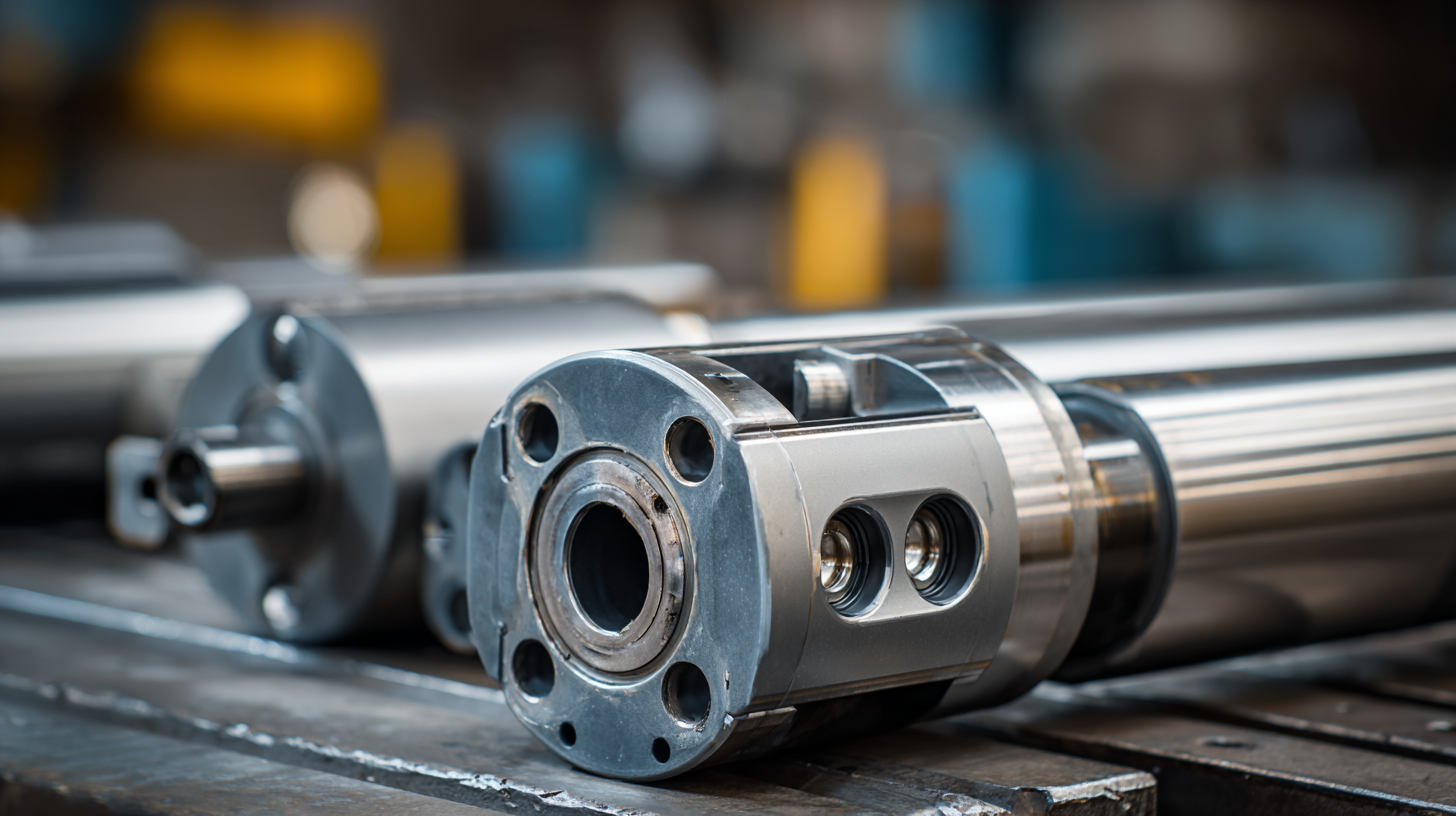

Understanding the Role of Cylinder Seals in Enhancing Flow Control and Reducing Leaks

Cylinder seals are critical components in hydraulic cylinders, playing a pivotal role in enhancing flow control and minimizing leaks. These seals create a tight barrier between the moving parts within the cylinder and the hydraulic fluid, ensuring that the pressure is maintained while allowing for smooth operation. An effective seal reduces the risk of fluid escaping, which can lead to efficiency losses and increased operational costs. By maintaining a sealed environment, hydraulic systems can achieve higher performance levels and respond more effectively to commands, thereby boosting overall machinery productivity.

Furthermore, the design and material of cylinder seals significantly influence their effectiveness. Advanced materials that withstand wear and tear, high pressure, and temperature changes ensure that the seals remain intact over prolonged use. Additionally, incorporating features like dynamic seals can enhance the functionality by allowing for proper movement while still maintaining a robust seal. This innovation is essential for minimizing downtime and ensuring that machinery functions at optimal levels, ultimately leading to improved efficiency and longer equipment lifespan.

Top 5 Hydraulic Cylinder Parts That Boost Performance and Efficiency in Machinery

| Part Name | Function | Material | Efficiency Boost (%) | Common Applications |

|---|---|---|---|---|

| Cylinder Seal | Prevents fluid leaks | Nitrile Rubber | 30 | Construction machinery, hydraulic systems |

| Rod Seal | Maintains pressure and controls fluid flow | Polyurethane | 25 | Industrial automation, marine applications |

| Piston Ring | Seals the piston to prevent fluid bypass | Steel | 20 | Agricultural equipment, lifting devices |

| Wiper Seal | Keeps contaminants out and protects seals | Viton | 15 | Excavators, mobile hydraulic systems |

| Backup Ring | Provides additional support to seals | PTFE | 10 | Industrial hydraulic systems, presses |

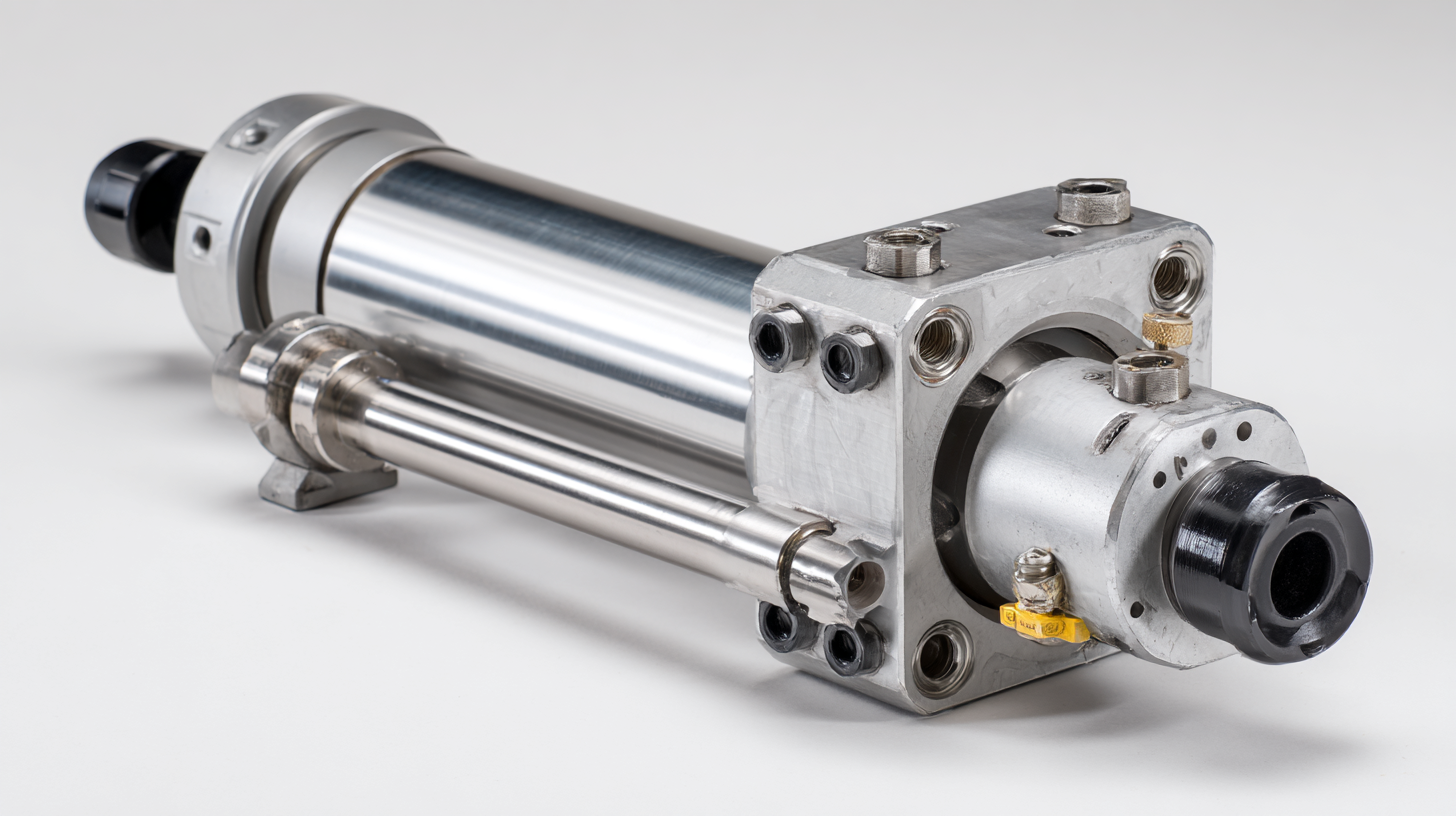

The Impact of Rod and Piston Material Selection on Durability and Weight Savings

The selection of materials for the rod and piston in hydraulic cylinders plays a crucial role in determining the overall performance and longevity of machinery. High-strength steel alloys are often favored for their durability, ensuring that these components can withstand the high pressures and repetitive stresses they encounter during operation. However, advancements in materials science have led to the exploration of lighter alternatives, such as aluminum and composite materials, which offer significant weight savings without compromising structural integrity. These innovations allow for machinery that is not only more efficient in performance but also easier to maneuver and transport.

Moreover, the balance between weight and durability is vital in optimizing the hydraulic system's efficiency. Lighter components can enhance response times and reduce energy consumption, ultimately leading to lower operational costs. Additionally, the choice of coatings and surface treatments can further increase resistance to wear and corrosion, thereby extending the lifespan of the cylinder parts. As manufacturers continue to prioritize performance and efficiency, the impact of material selection for the rod and piston in hydraulic cylinders will remain a central focus in design and engineering processes.

Analyzing the Advantages of Advanced Hydraulic Fluids for Enhanced Cylinder Performance

Advanced hydraulic fluids play a crucial role in enhancing the performance and efficiency of hydraulic cylinders in machinery. According to a report by the International Fluid Power Society, the use of high-quality hydraulic fluids can increase system efficiency by up to 15%, significantly reducing operational costs. These fluids are formulated to withstand higher temperatures and pressures, enabling them to perform optimally under demanding conditions. For instance, the adoption of synthetic hydraulic fluids has shown to improve lubricity and reduce wear on cylinder components, contributing to prolonged equipment life.

Moreover, the right hydraulic fluid can enhance the response time of hydraulic systems. A study published in the Journal of Fluid Power Research highlighted that advanced hydraulic fluids with improved viscosity index and anti-wear properties can reduce the lag time by approximately 20%. This responsiveness is essential in applications requiring precision and quick adjustments, such as in construction and manufacturing machinery. As manufacturers continue to innovate, the implementation of sophisticated hydraulic fluids is essential for achieving peak performance and operational efficiency in hydraulic systems.

Top 5 Hydraulic Cylinder Parts Performance Comparison

This chart displays the performance index of the top five hydraulic cylinder parts. The performance index indicates the efficiency and effectiveness of each component in enhancing the overall performance of hydraulic systems.

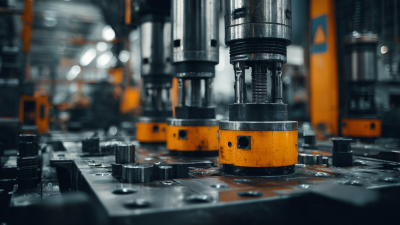

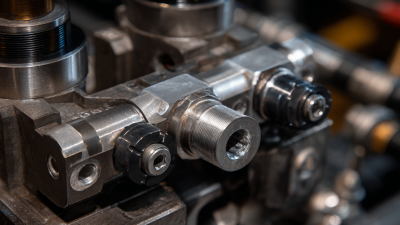

How Cylinder Valves Optimize Pressure Management for Maximal Machinery Output

Cylinder valves are critical components in hydraulic systems, playing a pivotal role in pressure management and overall machinery performance. By controlling the flow of hydraulic fluid, these valves help maintain optimal pressure levels, ensuring that hydraulic cylinders operate effectively. This not only enhances machinery output but also prolongs the lifespan of the equipment. Properly adjusted cylinder valves facilitate smoother operation, reducing wear and tear on components while maximizing productivity.

Cylinder valves are critical components in hydraulic systems, playing a pivotal role in pressure management and overall machinery performance. By controlling the flow of hydraulic fluid, these valves help maintain optimal pressure levels, ensuring that hydraulic cylinders operate effectively. This not only enhances machinery output but also prolongs the lifespan of the equipment. Properly adjusted cylinder valves facilitate smoother operation, reducing wear and tear on components while maximizing productivity.

Tips for Optimizing Cylinder Valve Performance: Regular maintenance of cylinder valves is essential for preventing pressure drops that can lead to inefficiencies. Inspecting seals and ensuring proper alignment can help maintain peak performance. Furthermore, using high-quality hydraulic fluids can reduce contamination and improve overall system reliability.

Another essential factor in optimizing cylinder valves is the correct selection of valve types based on the specific application. Understanding the operational requirements thoroughly can help engineers choose between different valve designs, such as poppet or spool valves, to achieve desired performance levels. This strategic approach not only enhances fluid control but also boosts the machine's operational efficiency.

Related Posts

-

10 Best Hydraulic Cylinder Parts You Should Know

-

Understanding the Key Components of Hydraulic Cylinder Parts

-

Innovative Solutions for Enhancing Efficiency with Hydraulic Cylinders in Manufacturing

-

Why Understanding Pneumatic and Hydraulic Systems is Essential for Modern Industries

-

Unlocking the Future of Machinery: Innovative Trends in Hydraulic Parts for Enhanced Efficiency

-

Understanding the Essential Role of Hydraulic Parts in Modern Machinery

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us