Why is Hydraulic Oil Essential for Machinery Performance?

Hydraulic oil plays a critical role in machinery performance across various industries. According to a report by the International Hydraulic Fluid Association, approximately 85% of industrial machinery relies on hydraulic systems for optimal operation. The right hydraulic oil ensures smooth movement, efficient power transfer, and effective lubrication, which are essential for machinery longevity.

In many cases, machinery performance declines due to poor hydraulic oil quality. Specifically, contaminated or degraded hydraulic oil can lead to increased wear and tear on components. A study from the Society for Tribologists and Lubrication Engineers (STLE) found that improper lubrication can reduce machinery life by up to 30%. It's clear that neglecting hydraulic oil maintenance can have significant financial implications for businesses.

Moreover, selecting the appropriate hydraulic oil is not always straightforward. Each machine has specific requirements that must be met for efficiency and reliability. Many operators overlook these details, leading to operational issues. Understanding the vital function of hydraulic oil is essential for anyone involved in machinery management. A focus on this crucial element will pay dividends in performance and reliability.

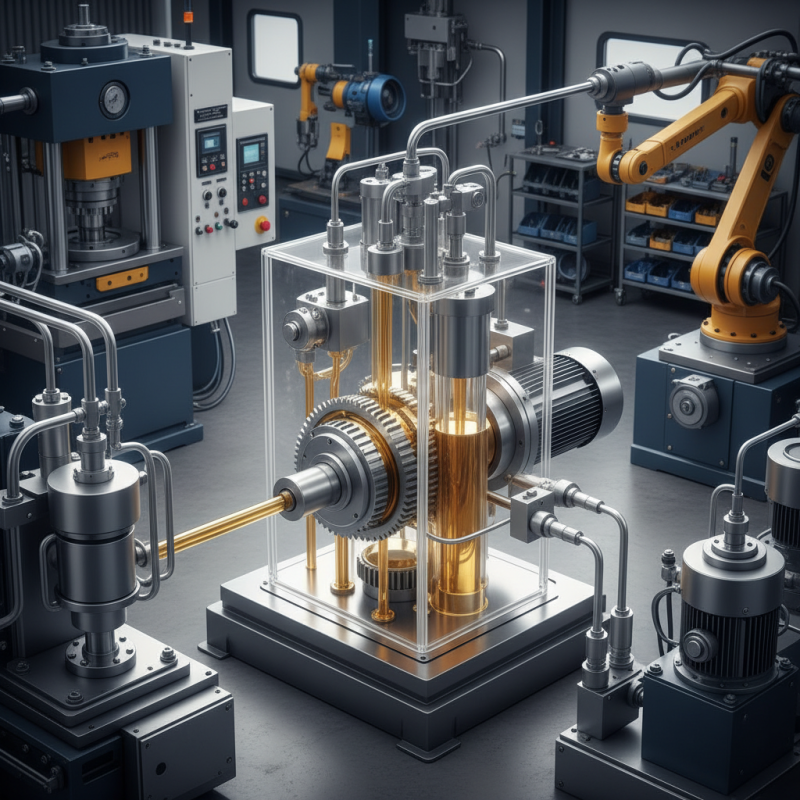

The Role of Hydraulic Oil in Machinery Operation

Hydraulic oil plays a vital role in machinery operation. It serves as the lifeblood of hydraulic systems, ensuring that components work efficiently. According to industry reports, hydraulic systems can improve energy efficiency by up to 30% when using the right oil. This is crucial for heavy machinery, where performance directly impacts productivity.

Proper lubrication is key. Hydraulic oil reduces friction and wear on moving parts. A study indicated that machinery with high-quality hydraulic oil can last 20% longer than those with subpar alternatives. Oil also carries out heat away from components, preventing overheating. In poorly maintained systems, overheating can lead to equipment failure, resulting in costly downtime.

Tips: Regularly check oil levels and quality. A simple visual inspection can reveal contamination or degradation. Change the oil according to the manufacturer’s guidelines. Keeping the hydraulic system clean can save time and money in repairs. Remember, even slight neglect can have significant consequences on performance. Opt for proper filtration to enhance longevity and efficiency. It’s imperative to stay vigilant.

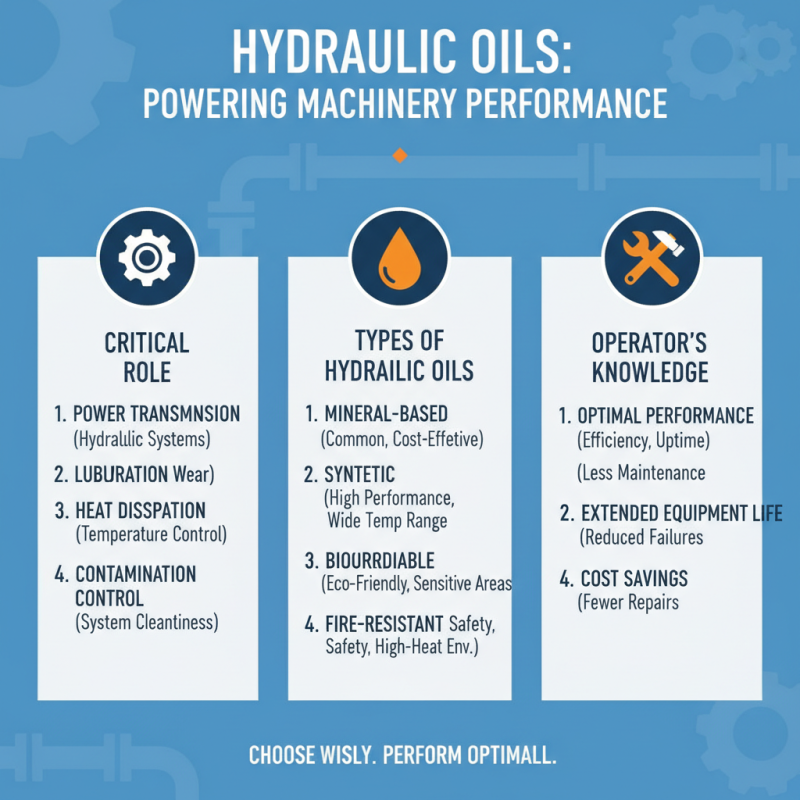

Types of Hydraulic Oils and Their Properties

Hydraulic oils play a critical role in machinery performance. They are essential for transmitting power in hydraulic systems. Understanding the different types of hydraulic oils is vital for any operator or technician. These oils vary in composition and properties, which directly affects their performance in high-pressure systems.

There are primarily two types of hydraulic oils: mineral-based and synthetic. Mineral oils are derived from refining crude oil. They are cost-effective and widely used. However, they often lack certain properties like thermal stability. Synthetic oils, in contrast, offer superior performance in extreme temperatures. They provide better lubrication and aging resistance. According to a 2022 industry report, synthetic oils can enhance machine efficiency by up to 30%.

The properties of hydraulic oils include viscosity, lubrication ability, and temperature stability. For example, the viscosity index ensures that the oil maintains a consistent thickness across temperature variations. Oils with high viscosity index numbers offer better stability. However, selecting the wrong type can lead to equipment failure. An incorrect viscosity may cause slippage in hydraulic pumps or increase wear on components. Operators must remain vigilant about oil selection and maintenance.

How Hydraulic Oil Affects Machine Efficiency

Hydraulic oil plays a critical role in machinery performance. Studies show that the viscosity of hydraulic oil affects energy loss in hydraulic systems. A report from an industry association states that improper viscosity can increase energy consumption by up to 15%. This inefficiency can lead to significant operational costs over time. Using the correct hydraulic oil ensures better lubrication and heat dissipation, which enhances machine performance.

Moreover, hydraulic oil's cleanliness is vital for machine efficiency. Contaminants in the oil can cause wear and tear on components. It was noted that approximately 70% of hydraulic system failures are due to contaminated fluids. Regularly monitoring and replacing hydraulic oil can mitigate these issues, preserving machinery lifespan.

Temperature also plays a role. Hydraulic fluids can lose efficiency at higher temperatures, especially if the oil degrades. Data indicates that a 10°C increase in oil temperature can double the rate of oxidation. This leads to poor performance. Therefore, understanding the effects of hydraulic oil on machinery performance is essential for optimal efficiency.

Hydraulic Oil Impact on Machinery Performance

Common Issues Caused by Poor Hydraulic Oil Quality

Hydraulic oil plays a crucial role in the performance of machinery. However, poor-quality hydraulic oil can lead to significant issues. One common problem is increased wear and tear on components. Contaminated oil contains particles that damage seals and pumps. This damage often leads to costly repairs and downtime.

Another issue stems from inadequate lubrication. When hydraulic oil is degraded, it loses its ability to reduce friction. This can cause overheating in systems, which in turn affects performance. Machinery may operate less efficiently, consuming more energy. In severe cases, it could result in operational failure.

Furthermore, poor oil quality can lead to hydraulic fluid foaming. This diminishes the oil's ability to transmit power effectively. Foaming can also cause erratic movements in the machinery, creating safety hazards. Regular maintenance and oil checks are essential. A proactive approach ensures that machinery runs smoothly and reduces the risk of these common problems.

Best Practices for Maintaining Hydraulic Oil in Machinery

Hydraulic oil is a key player in machinery performance. The right maintenance practices are essential to ensure it operates efficiently. Regular monitoring of oil levels can prevent system failures. According to a 2022 industry report, nearly 70% of hydraulic system failures are due to poor oil maintenance. This highlights the importance of proactive measures.

Changing hydraulic oil regularly is crucial. Contaminants build up over time, leading to decreased efficiency. The ideal interval for oil changes is typically every 1,000 operating hours. Furthermore, using a proper filtration system can significantly extend oil life. A study found that clean oil can last up to three times longer than contaminated oil.

Proper storage of hydraulic oil is often overlooked. Exposure to extreme temperatures can lead to viscosity changes. This impacts the oil's performance. Additionally, proper labeling helps prevent confusion during refills. Simple steps like these can improve machinery longevity and reliability. Balancing cost and maintenance is essential for optimal performance.

Related Posts

-

The Essential Guide to Choosing the Right Hydraulic Oil for Optimal Machinery Performance

-

Unlocking Hydraulic Repair Excellence A Comprehensive Guide to Efficient Solutions

-

How to Optimize Air Hydraulic Pump Performance for Maximum Efficiency

-

Understanding the Power Behind Fluid Power Hydraulics in Everyday Machines

-

Unveiling the Future of Fluid Power Hydraulics in Sustainable Engineering

-

How to Choose Hydraulic Cylinder Parts for Optimal Performance?

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us