Unlocking Efficiency: How a Hydraulic Power Pack Transforms Industrial Applications

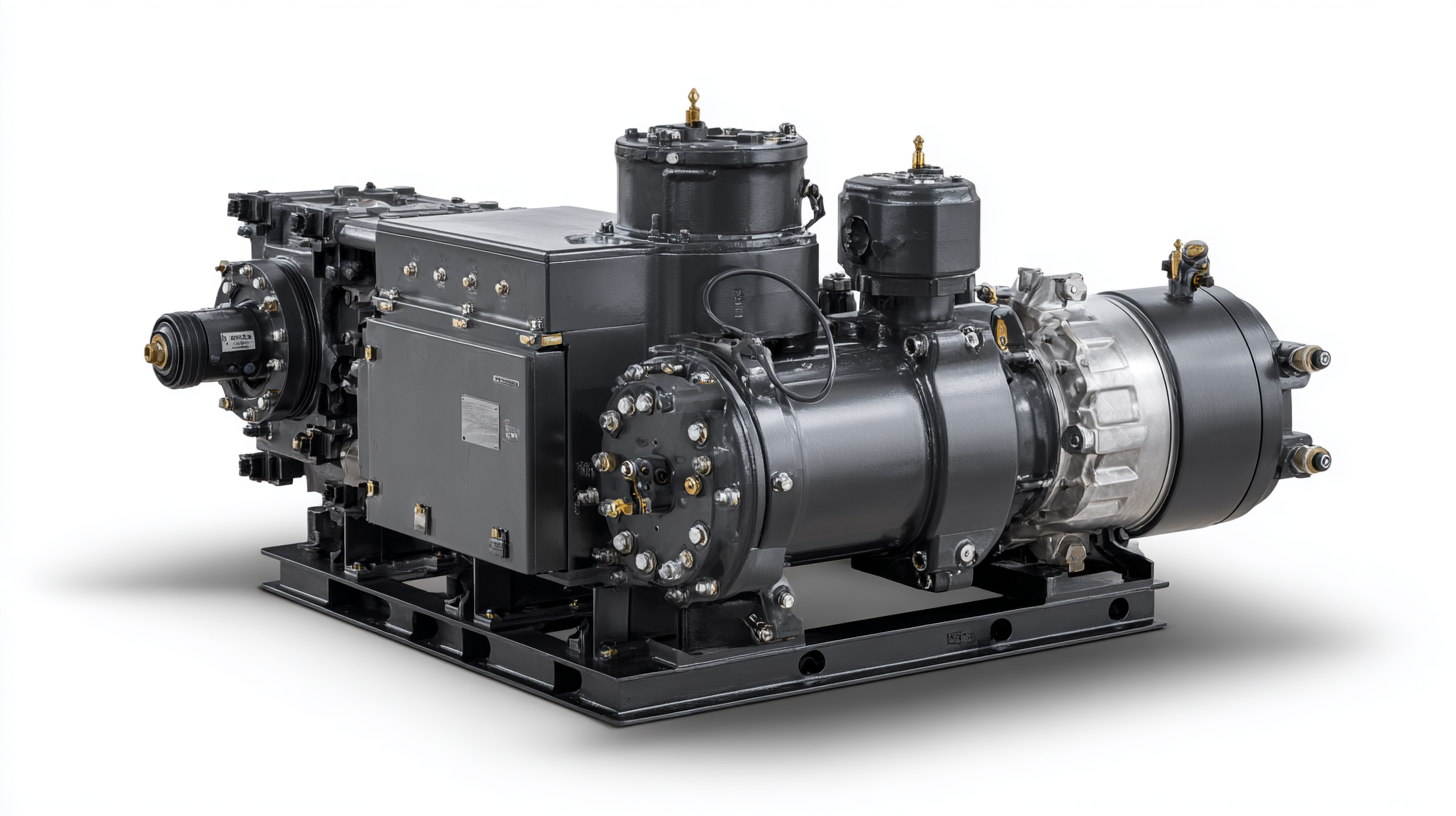

In today's rapidly evolving industrial landscape, companies are continuously seeking ways to enhance productivity and reduce operational costs. A pivotal innovation in this pursuit is the hydraulic power pack, a system that has been reported to improve efficiency in various applications by up to 20%, according to a recent market analysis by ResearchAndMarkets.com. These robust units are designed to deliver high power for numerous machinery, offering superior torque and reliability while minimizing energy consumption.

The Critical Role of Hydraulic Power Packs in Enhancing Operational Efficiency

Hydraulic power packs play a crucial role in enhancing operational efficiency across various industrial applications. By providing a reliable source of hydraulic energy, these units enable machinery and equipment to perform tasks with precision and speed. The ability to control pressure and flow rates effectively allows industries to optimize their processes, reduce downtime, and minimize energy consumption. This efficiency not only translates to lower operational costs but also supports sustainable practices by reducing waste and resource usage.

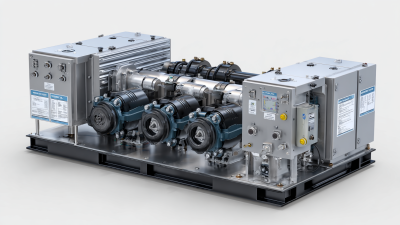

Moreover, hydraulic power packs offer versatility that makes them indispensable in numerous sectors, including construction, manufacturing, and logistics. Their modular design allows for easy integration into existing systems, enhancing flexibility for various applications. Whether it’s powering hydraulic lifts, presses, or automated machinery, these power units ensure that operations run smoothly and efficiently. As industries continue to strive for higher productivity and reduced environmental impact, the importance of hydraulic power packs in optimizing processes cannot be overstated. Their contribution to streamlining operations and improving overall effectiveness positions them as an essential component of modern industrial strategies.

Comparative Analysis: Hydraulic Power Packs vs. Electric Systems in Industry

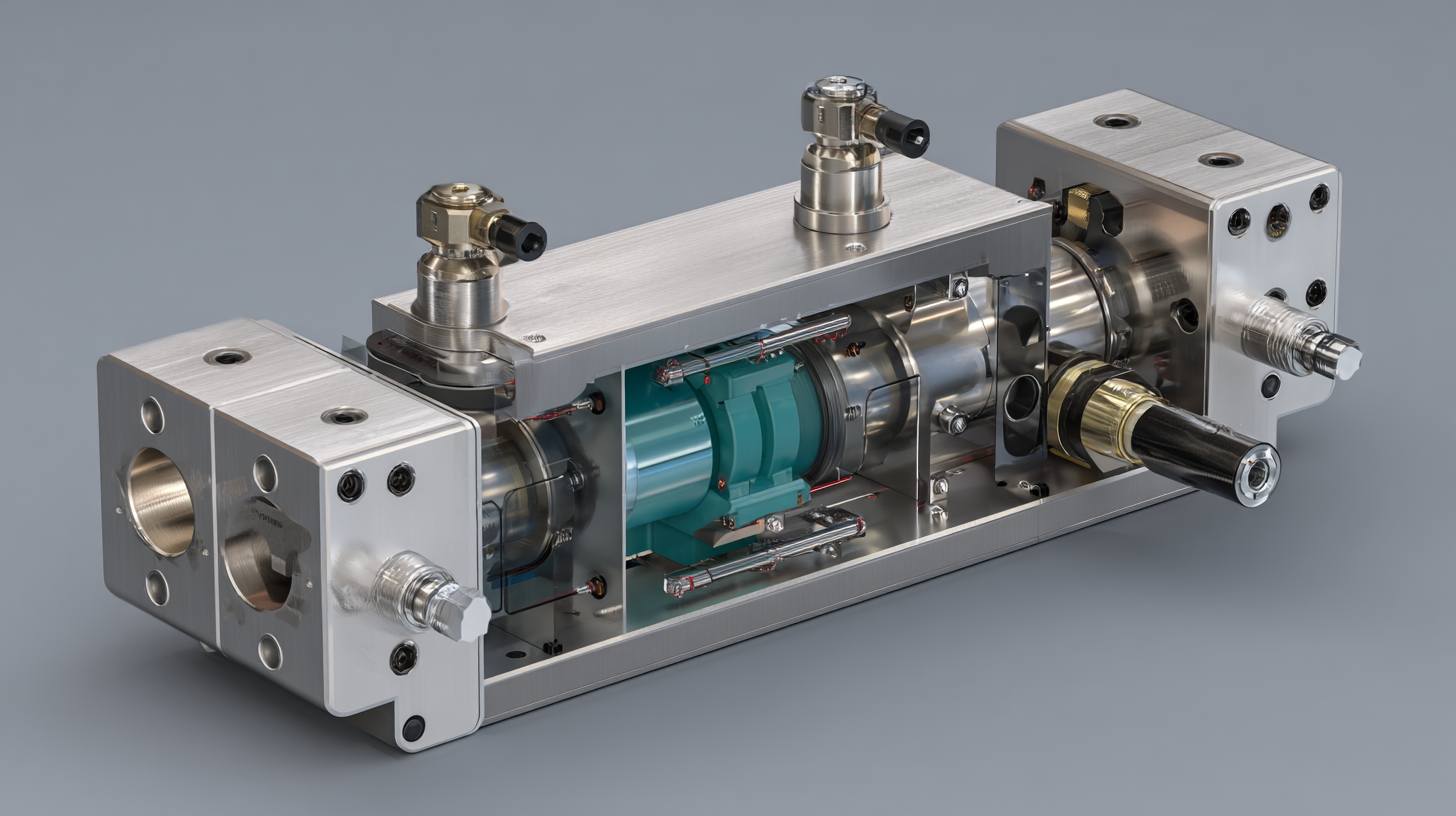

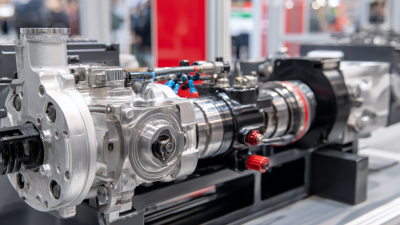

The comparative analysis between hydraulic power packs and electric systems in industrial applications reveals significant differences in efficiency, performance, and adaptability. Hydraulic power packs are known for their high power-to-weight ratio and ability to deliver consistent force in demanding environments. This makes them particularly advantageous in heavy machinery operations, such as construction and manufacturing, where reliability and strength are paramount. They excel in applications requiring precise control and immediate response, leading to enhanced productivity.

On the other hand, electric systems are increasingly being adopted due to their lower maintenance costs and environmental considerations. Electric actuators provide smoother operation and higher energy efficiency, especially in scenarios with variable load conditions. With advancements in battery technology and smart control systems, electric solutions are becoming more viable, contributing to the trend of electrification in various sectors. Ultimately, the choice between hydraulic power packs and electric systems will depend on the specific needs of the application, balancing factors such as power requirements, operational costs, and environmental impact.

Key Industries Benefiting from Hydraulic Power Pack Integration

Hydraulic power packs are becoming increasingly vital across various industries, revolutionizing how tasks are accomplished. In the construction sector, these power packs enhance the efficiency of heavy equipment by providing consistent and reliable hydraulic pressure. This enables machines like excavators and lifts to perform complex tasks, such as digging and lifting, with greater precision and reduced operational time. The seamless integration of hydraulic systems allows construction professionals to leverage significant power without compromising on mobility or performance.

Furthermore, the manufacturing industry has witnessed remarkable enhancements through hydraulic power pack implementation. Automated assembly lines benefit from the strength and adaptability of hydraulic systems, allowing for intricate assembly processes that would be impossible with mechanical systems alone. These hydraulic solutions provide flexibility, as they can be easily adjusted to meet variable production demands, thus reducing downtime and increasing overall productivity. Industries like automotive and aerospace utilize hydraulic power packs to streamline operations, ensuring that production not only meets standards but exceeds efficiency targets.

Quantifying Productivity Gains: Metrics for Assessing Hydraulic Power Pack Impact

The role of hydraulic power packs in industrial applications cannot be overstated, as they significantly enhance productivity and efficiency. Quantifying the gains from using hydraulic power packs involves a variety of metrics, such as energy consumption reduction, output increase, and downtime minimization. For instance, industries can measure the time saved in production cycles and assess how hydraulic power packs enable faster response times to market demands. By analyzing these metrics, companies can develop a clearer understanding of the return on investment and the long-term benefits of integrating hydraulic systems into their operations.

Moreover, the assessment of hydraulic power packs' impact also intersects with broader environmental and economic considerations. As industries adapt to climate-related challenges, the efficient use of hydraulic power systems contributes to more sustainable practices. For example, reduced energy consumption correlates positively with lower carbon footprints, while the optimized use of water resources enhances resilience against water scarcity risks. In this context, adopting hydraulic power packs not only serves immediate operational goals but also aligns with strategic objectives of corporate sustainability and risk management in a changing environment.

Unlocking Efficiency: How a Hydraulic Power Pack Transforms Industrial Applications

| Application Area | Productivity Gain (%) | Cost Savings ($) | Operational Hours Saved | Environmental Impact (CO2 Reduced, kg) |

|---|---|---|---|---|

| Construction | 25% | $12,000 | 500 | 200 |

| Manufacturing | 30% | $25,000 | 800 | 350 |

| Agriculture | 20% | $8,000 | 300 | 150 |

| Mining | 35% | $30,000 | 1,000 | 500 |

| Transportation | 15% | $5,000 | 200 | 100 |

Future Trends: Innovations in Hydraulic Power Pack Technology and Applications

The advancements in hydraulic power pack technology are poised to revolutionize various industrial applications. Innovations such as smart sensors and IoT integration are enabling real-time monitoring and optimization of hydraulic systems. These technologies facilitate predictive maintenance, reducing downtime and operational costs while enhancing overall efficiency. Furthermore, the integration of energy-efficient components is leading to significant reductions in power consumption, aligning with global sustainability goals and regulatory standards.

In addition to efficiency improvements, the future of hydraulic power pack technology looks promising with the rise of modular designs and customizable solutions. This flexibility allows industries to adapt their hydraulic systems to diverse needs, fostering innovation in manufacturing processes and equipment. As electric and hybrid technologies converge with hydraulic systems, the potential for lighter, more compact power packs becomes apparent, offering enhanced performance in confined spaces. These trends indicate a dynamic shift in how industries will leverage hydraulic power, pushing the boundaries of capability and application.

Unlocking Efficiency: Hydraulic Power Pack Performance in Industrial Applications

This chart illustrates the efficiency gain in various industrial applications utilizing hydraulic power packs. The data showcases an increase in productivity measured in terms of output per hour across different sectors, reflecting the transformative impact of hydraulic technology.

Related Posts

-

Understanding the Essential Role of Hydraulic Power Packs in Modern Machinery

-

Exploring Hydraulic Pumps and Motors Innovations at the 138th Canton Fair 2025: Industry Insights

-

Unveiling the Future of Fluid Power Hydraulics in Sustainable Engineering

-

Top Strategies for Optimizing Hydraulic System Efficiency

-

5 Essential Tips for Choosing the Right Hydraulic Pump Motor for Your Industrial Needs

-

Unlocking Hydraulic Repair Excellence A Comprehensive Guide to Efficient Solutions

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us