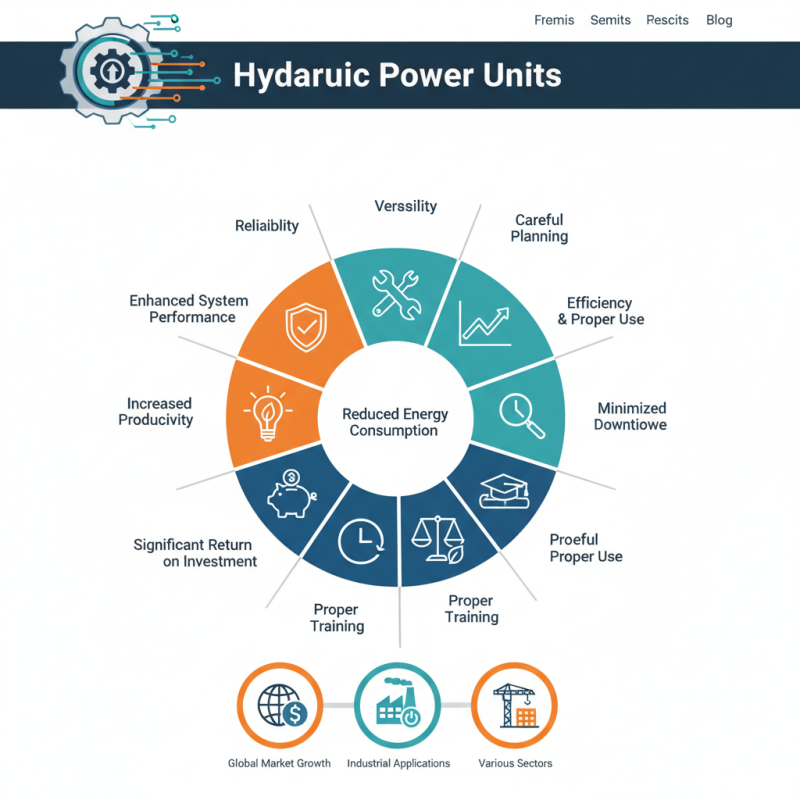

Top 10 Benefits of Using Hydraulic Power Units for Your Projects?

Hydraulic power units (HPUs) play a crucial role in modern engineering and industrial applications. According to a recent industry report, the global hydraulic equipment market is projected to reach $50 billion by 2025. This growth is largely driven by increased demand for reliable and efficient power sources across various sectors. Using an HPU can enhance system performance and reliability.

One notable aspect of HPUs is their versatility. They can be customized for numerous applications, from construction to manufacturing. Anecdotal evidence shows that companies using HPUs report a measurable increase in productivity, often citing improved operational efficiency. However, there are challenges. Not all systems are designed to integrate seamlessly with HPUs. This can lead to additional costs and project delays.

Despite the potential drawbacks, the benefits are compelling. HPUs reduce energy consumption and minimize downtime during operations. When properly implemented, they can provide a significant return on investment. Nevertheless, careful planning and evaluation are essential. Many organizations overlook proper training for personnel, which can undermine the benefits of adopting hydraulic power units. The balance between efficiency and proper use remains a critical consideration for any project manager.

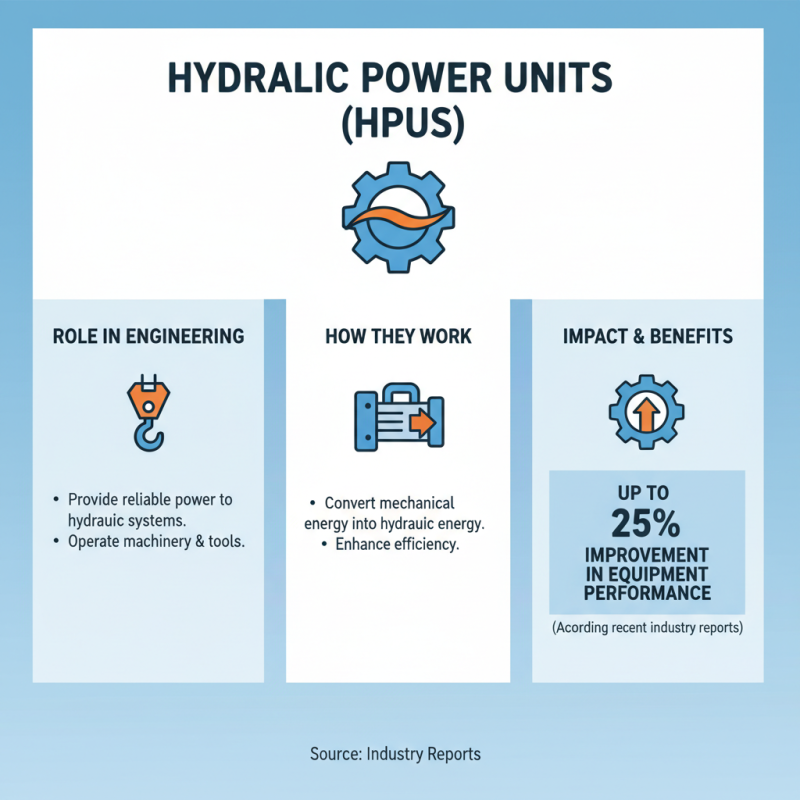

Overview of Hydraulic Power Units and Their Functionality

Hydraulic Power Units (HPUs) play a vital role in modern engineering projects. They provide reliable power to hydraulic systems that operate machinery and tools. By converting mechanical energy into hydraulic energy, they enhance efficiency in various applications. According to recent industry reports, HPUs can improve equipment performance by up to 25%.

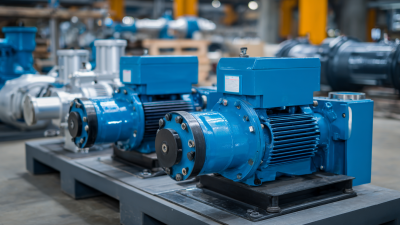

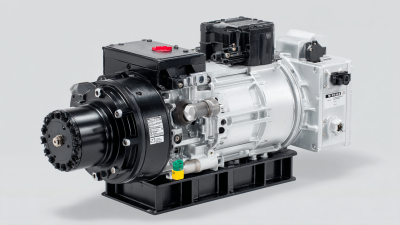

Typically, HPUs consist of a motor, pump, reservoir, and control mechanisms. This setup allows them to supply pressurized fluid to hydraulic devices. The controlled pressure helps in executing tasks such as lifting, pushing, and bending materials accurately. A well-designed HPU ensures smooth operation, yet improper installation can lead to inefficiencies and malfunctions.

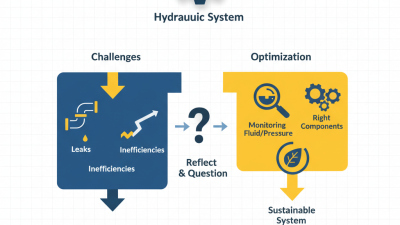

Tips: Choose the right motor size. An oversized motor can lead to energy waste. Regular maintenance is crucial. Check for leaks and pressure irregularities to prevent downtime.

Incorporating HPUs can shorten project completion times. However, teams need to be cautious about their technical knowledge. Underestimating the complexity of hydraulic systems can be detrimental. The learning curve is steep for new users, so investing time in proper training is essential. This investment pays off through improved productivity and reduced costs.

Key Advantages of Hydraulic Power Units in Project Efficiency

Hydraulic power units (HPUs) play a crucial role in boosting project efficiency. These units convert hydraulic energy into mechanical energy, enabling smooth function in various applications. They thrive in areas such as construction, manufacturing, and marine industries. By providing high force capability, HPUs streamline the completion of tasks that involve heavy lifting and precise movements.

One critical advantage is their adaptability. HPUs can be customized to meet specific project needs, making them versatile tools. The speed of operation is another highlight; tasks can be completed faster than with other power sources. However, there can be challenges. Maintenance is essential. Neglecting it could lead to downtime, affecting overall project timelines. Operators must train adequately to avoid mishaps, as a lack of knowledge can create hazards.

Moreover, understanding fluid dynamics is vital. Hydraulic systems require careful consideration of fluid properties and potential leakage issues. This complexity can be daunting for some teams. Despite these challenges, the efficiency gained from using HPUs often outweighs the drawbacks. The integration of hydraulic technology can significantly enhance productivity and effectiveness in project execution.

Cost Savings and Maintenance Benefits of Hydraulic Power Systems

Hydraulic power units (HPUs) offer significant cost savings for various projects. Reports indicate that companies can reduce operational costs by up to 30% when switching to hydraulic systems. This reduction comes from lower energy consumption and less manual labor. The reliability of hydraulic power can also minimize downtime, which is crucial for project timelines.

Maintenance is another key advantage of hydraulic power systems. Regular maintenance can extend the lifespan of the equipment. Reports show that proper upkeep can double the life of hydraulic components compared to other systems. However, it’s essential to train staff adequately. Neglecting training can lead to costly mistakes and repairs.

Tip: Schedule routine checks on hydraulic systems to prevent major issues.

Using hydraulic power also often means fewer parts and simplified systems. Although some may argue that the initial investment for hydraulic equipment is high, the long-term savings are worth it. It can be frustrating dealing with complex machinery, yet understanding the advantages can make the transition beneficial.

Tip: Invest in employee training to maximize system efficiency.

Top 10 Benefits of Using Hydraulic Power Units for Your Projects

Applications of Hydraulic Power Units Across Different Industries

Hydraulic power units (HPUs) play a vital role across various industries. In construction, they are essential for powering heavy equipment. Data from the International Construction Market Report highlights that 60% of construction machinery utilizes hydraulic systems. This increases efficiency and safety on job sites. For instance, excavators rely on HPUs for digging and lifting, thus optimizing workflow.

In the automotive sector, HPUs are critical for systems like braking and steering. The automotive industry report reveals that over 70% of vehicles employ hydraulic components. However, some manufacturers face challenges in maintenance and efficiency. Downtime can be costly, impacting production schedules. This reflects the need for regular assessments of hydraulic systems to ensure reliability.

The marine industry also benefits significantly from HPUs. They handle tasks such as controlling cranes and powering winches. A study by the Marine Technology Society states that hydraulic systems are found in 80% of marine vessels. Yet, there can be concerns about energy efficiency and environmental impact. Companies are urged to innovate and seek sustainable solutions while still relying on hydraulic power.

Future Trends in Hydraulic Power Technology and Their Implications

The future of hydraulic power technology shows significant progression. Recent reports indicate that the global market for hydraulic power units is projected to grow at a CAGR of 5.3% over the next five years. This growth is largely driven by the increasing demand for efficient energy solutions across various industries. Companies are investing in advanced technologies to enhance the performance and reliability of hydraulic systems.

Innovations like IoT integration and smart system monitoring are gaining traction. These technologies enable real-time data analysis and predictive maintenance. A 2022 study suggested that predictive maintenance could reduce equipment downtime by up to 30%. However, the implementation of these technologies often faces resistance. Many organizations hesitate to invest in new systems due to high initial costs and training needs.

Moreover, sustainability is becoming a core focus in hydraulic power technology. Reports show that reducing energy consumption in hydraulic systems can enhance operational efficiency by 20% or more. Yet, the challenge remains. Transitioning to greener solutions demands significant changes in design and materials. Companies must reflect on how to balance innovation with practicality.

Related Posts

-

How to Optimize Your Hydraulic System for Better Performance?

-

How to Optimize Air Hydraulic Pump Performance for Maximum Efficiency

-

How to Choose the Right Hydraulic Pumps and Motors for Your Industrial Needs

-

Unlocking Efficiency with Hydraulic Power Packs Understanding Their Impact on Industrial Applications

-

7 Best Hydraulic Motors for Efficient Energy Solutions in 2024

-

Why Understanding Hydraulic Oil is Essential for Equipment Longevity

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us