What is Hydraulic Pump Repair and Why It Matters for Industry Efficiency

Hydraulic pump repair is a critical maintenance task that significantly impacts the efficiency of industrial operations. In a world where machinery plays an essential role in productivity, ensuring that hydraulic systems function at their peak is vital.

Hydraulic pumps drive various processes, from manufacturing and construction to agriculture, and any malfunction can lead to costly downtime and hindered performance. Understanding the intricacies of hydraulic pump repair is not just about fixing equipment; it is about preserving the overall workflow and enhancing the longevity of machinery.

Hydraulic pumps drive various processes, from manufacturing and construction to agriculture, and any malfunction can lead to costly downtime and hindered performance. Understanding the intricacies of hydraulic pump repair is not just about fixing equipment; it is about preserving the overall workflow and enhancing the longevity of machinery.

As industries strive for improved efficiency and reduced operational costs, recognizing the importance of timely and effective hydraulic pump repair becomes paramount. This guide will explore the significance of this process, shedding light on its benefits, common issues, and best practices for ensuring that hydraulic systems remain reliable and efficient.

Understanding Hydraulic Pumps: Key Components and Their Functions

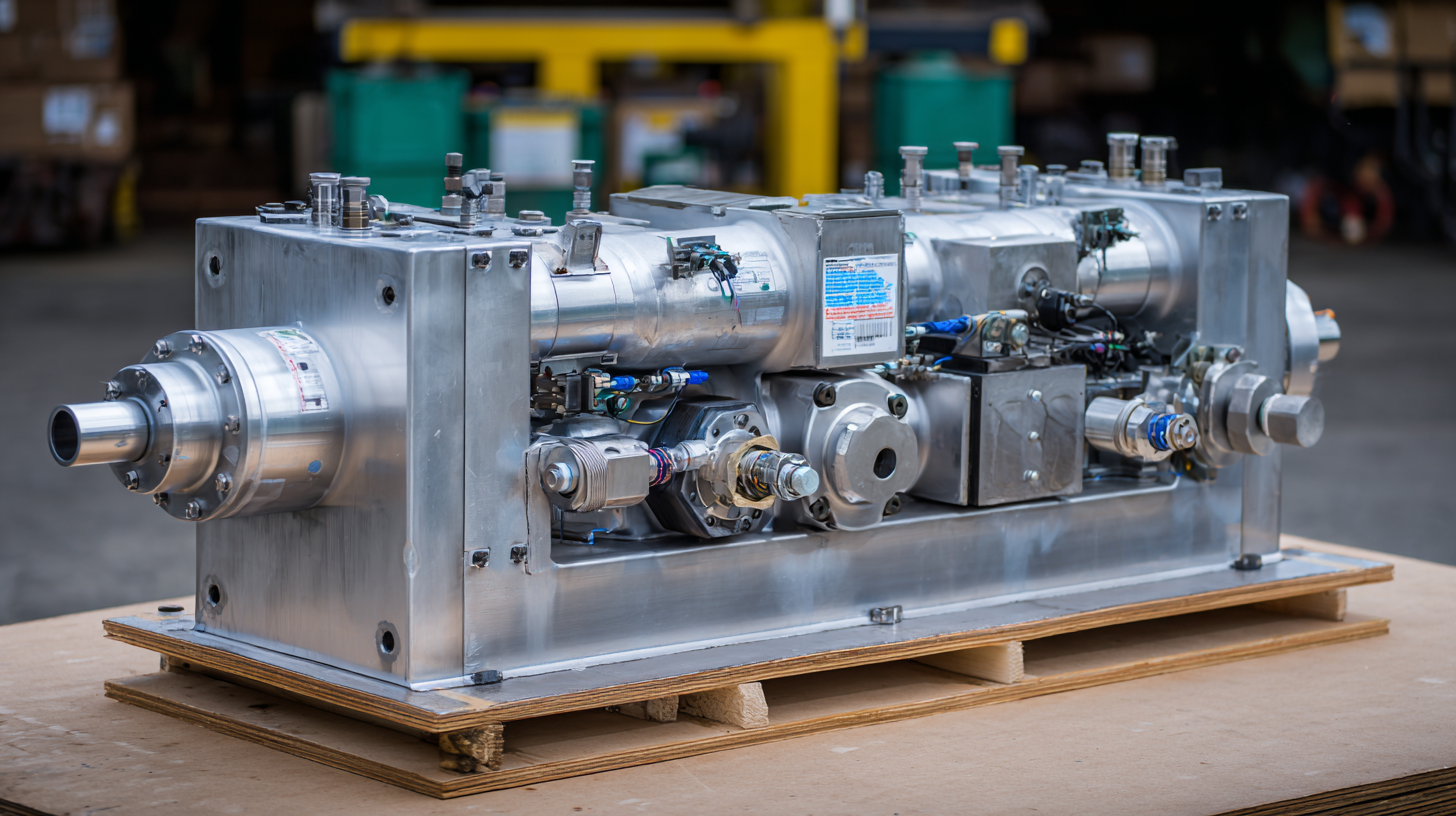

Hydraulic pumps are essential components in various industrial applications, converting mechanical energy into hydraulic energy to power machinery and systems. Understanding the key components of hydraulic pumps is crucial for maintaining operational efficiency. These pumps typically consist of several critical parts, including the housing, gears or pistons, and seals. According to a report by the National Fluid Power Association, hydraulic pumps account for about 80% of the total energy consumption in hydraulic systems, highlighting their significant role in industrial performance.

The efficiency of hydraulic pumps is largely influenced by their design and maintenance. For instance, gear pumps are known for their simplicity and reliability, making them suitable for many applications, while piston pumps offer higher pressure capabilities. Regular maintenance and timely repair can prevent costly downtimes and extend the lifespan of these pumps. Industry data indicates that a welle-maintained hydraulic system can improve energy efficiency by up to 30%, substantially reducing operational costs. As industries continue to prioritize sustainability, understanding the functions and components of hydraulic pumps becomes paramount for ensuring optimal performance.

Common Signs Your Hydraulic Pump Needs Repair: Don't Ignore These Warning Signs

Hydraulic pumps are essential components in many industrial settings, but they may show signs of wear and tear that can lead to significant operational inefficiencies. According to a report by the International Society for Reliability Engineering, approximately 30% of hydraulic system failures can be attributed to pump issues. Recognizing these critical warning signs is crucial for maintaining operational efficiency and avoiding costly downtime.

One prevalent sign that a hydraulic pump needs repair is unusual noise or vibration. A well-functioning hydraulic pump operates smoothly and silently; thus, any rattling or grinding noises likely indicate internal wear or misalignment. Additionally, a drop in pressure can signal issues, as hydraulic systems rely on consistent pressure levels to function effectively. Research by the Hydraulic Institute indicates that even a 10% drop in pump efficiency can result in a 5% increase in energy consumption, which is an important consideration for industries looking to optimize costs. Addressing these signs promptly can enhance system longevity and maintain productivity in any hydraulic-driven operation.

What is Hydraulic Pump Repair and Why It Matters for Industry Efficiency

| Signs Your Hydraulic Pump Needs Repair | Description | Impact on Efficiency | Recommended Action |

|---|---|---|---|

| Unusual Noises | Grinding or squealing noises indicating internal damage or wear. | Reduced operational efficiency, leading to longer cycle times. | Conduct an inspection and repair or replace damaged components. |

| Leaking Fluid | Fluid leaks indicate potential seal failure or cracks in the housing. | Loss of hydraulic fluid affects pressure and output, resulting in inefficient operations. | Address the source of the leak immediately, checking seals and fittings. |

| Overheating | Elevated temperatures can damage internal parts and fluids. | Operational downtime and increased energy consumption. | Check the cooling system and fluid levels; consider flushing the system. |

| Decreased Performance | Lack of power or slow response when operating hydraulic machinery. | Inefficient cycle times and potential delays in production. | Evaluate performance and conduct diagnostic tests for potential issues. |

| Vibration | Excessive vibrations indicate imbalance or wear in the pump assembly. | May lead to further mechanical failures and increased maintenance costs. | Inspect for alignment issues and rectify them promptly. |

Step-by-Step Guide to Hydraulic Pump Repair: Tips from Industry Experts

Hydraulic pump repair is crucial for ensuring that machinery operates efficiently and reliably. In this step-by-step guide, we’ll explore expert tips that can help you navigate the repair process effectively. First, it’s essential to diagnose the problem accurately. Look for common signs of failure such as unusual noises, leaks, or loss of pressure. Understanding the specific issues with your hydraulic pump allows you to address them directly and avoid unnecessary repairs.

Once the problem is identified, gathering the right tools and replacement parts is key. Experts recommend having a comprehensive toolkit that includes wrenches, seals, and filters tailored for your pump model. Additionally, following the manufacturer’s service manual can guide you through the disassembly and assembly processes. Don’t forget to check for wear and tear on internal components like gears and bearings, as these often require attention to prevent future malfunctions. Engaging in thorough maintenance not only extends the lifespan of your hydraulic pump but also improves overall system performance, contributing to greater industrial efficiency.

Hydraulic Pump Repair Trends in Industrial Efficiency

The Impact of Efficient Hydraulic Pump Maintenance on Overall Industry Productivity

Efficient hydraulic pump maintenance is crucial for enhancing overall industry productivity. Hydraulic pumps are the heart of many industrial systems, powering critical operations in manufacturing, construction, and other sectors. When maintained properly, these pumps function at optimal levels, ensuring that machinery runs smoothly and reducing the likelihood of unexpected breakdowns. This reliability translates directly into increased productivity, as well-maintained systems minimize downtime and allow for continuous operations.

Moreover, neglecting hydraulic pump maintenance can lead to significant inefficiencies. Wear and tear, combined with a lack of regular inspections, can cause pumps to operate below their design specifications. This not only affects the performance of the hydraulic system but also leads to higher energy consumption and increased operating costs. By investing in routine maintenance and timely repairs, industries can not only prolong the lifespan of their hydraulic systems but also achieve substantial gains in operational efficiency. Therefore, prioritizing hydraulic pump repair serves as a cornerstone for maintaining competitive advantage in today's fast-paced industrial landscape.

Cost-Benefit Analysis: Investing in Hydraulic Pump Repairs vs. Replacements

Hydraulic pump repairs are often a crucial consideration for industries relying on hydraulic systems for their operations. When faced with malfunctioning equipment, companies must decide between investing in repairs or opting for replacements. Conducting a cost-benefit analysis can illuminate the most financially viable option. Repairs typically involve lower upfront costs and can extend the life of the existing pump, minimizing disruption to production. Additionally, effective repairs can enhance operational efficiency, as restored components often perform better than before.

On the other hand, replacement might seem appealing for the promise of new technology and warranties. However, it entails higher initial expenses and potential downtime. When evaluating the long-term implications, repairs often yield a more favorable return on investment. Factors such as the age of the pump, frequency of issues, and the specific demands of the operation should all be considered. Ultimately, a thorough assessment of both options can guide businesses in making strategic decisions that bolster efficiency and productivity in the long run.

Related Posts

-

Ultimate Checklist for Efficient Hydraulic Pump Repair Maintenance

-

Understanding Common Issues with Hydraulic Pumps and Motors in Industrial Applications

-

7 Compelling Reasons to Choose Fluid Power Hydraulics for Your Industrial Needs

-

10 Essential Tips for Mastering Pneumatic and Hydraulic Systems

-

How to Optimize Air Hydraulic Pump Performance for Maximum Efficiency

-

Understanding the Key Components of Hydraulic Cylinder Parts

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us