Top 10 Hydraulic Pumps: Ultimate Guide to Performance and Efficiency

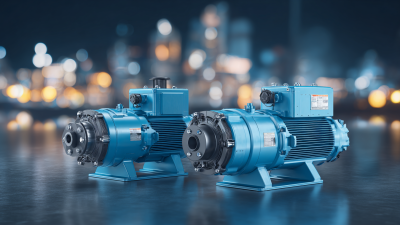

The efficiency and performance of hydraulic pumps play a crucial role in a variety of industrial applications, influencing everything from construction machinery to manufacturing processes. According to a report by MarketsandMarkets, the global hydraulic pump market is projected to reach USD 16.6 billion by 2025, growing at a CAGR of 4.4% from 2020. This growth underscores the importance of selecting the right hydraulic pump to maximize operational effectiveness and minimize energy consumption.

Experts in the field, such as Dr. Robert Morgan, a renowned hydraulic systems consultant, emphasize the significance of choosing high-performance hydraulic pumps tailored to specific applications. He states, "The right hydraulic pump not only enhances system efficiency but also extends equipment longevity." As industries across the globe continue to strive for greater productivity, understanding the top hydraulic pumps available on the market becomes essential for engineers and decision-makers alike.

In this ultimate guide, we will explore the top 10 hydraulic pumps, assessing their performance metrics, efficiencies, and application suitability. By delving into the latest innovations and technologies driving this sector, we aim to equip industry professionals with the insights needed to make informed selections that contribute to operational success.

Key Features to Consider When Choosing a Hydraulic Pump

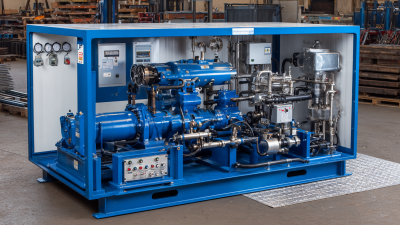

When selecting a hydraulic pump, several key features must be considered to ensure optimal performance and efficiency. One of the most critical factors is the pump type, which can vary between gear, vane, and piston pumps. Each type offers distinct advantages, such as ease of maintenance or higher pressure capabilities. Understanding the specific demands of your application, including the required flow rate and pressure, will help in choosing the right pump type.

Another vital consideration is the pump's materials and construction. Hydraulic pumps are often subjected to harsh environments, so durability and resistance to wear and corrosion should be prioritized. Additionally, the pump's efficiency, typically measured by its volumetric efficiency and overall efficiency, can dramatically influence operational costs. A more efficient pump will not only save energy but also reduce heating and wear on the system, leading to lower maintenance costs in the long run. Ensuring the compatibility of the pump with existing hydraulic fluids and systems is also essential for seamless integration and longevity.

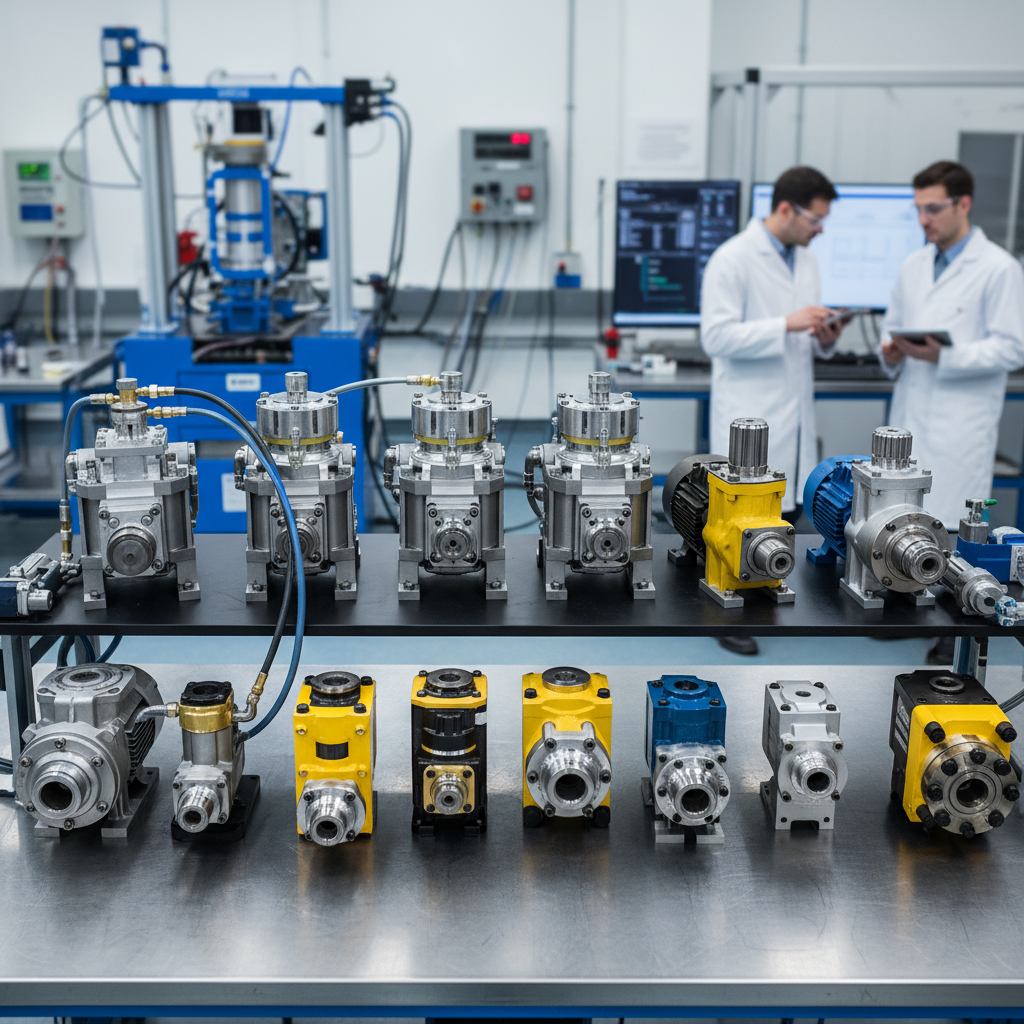

Comparative Analysis of the Top 5 Hydraulic Pump Brands

When evaluating the top five hydraulic pump brands, performance and efficiency are paramount. Leading brands such as Bosch Rexroth, Parker Hannifin, and Eaton are recognized for their advanced engineering and robust designs, which translate to superior hydraulic performance across various applications. Bosch Rexroth, for instance, is known for its high-pressure pumps that deliver consistent performance while minimizing energy consumption. This efficiency is crucial for industries requiring sustained operational uptime and reduced operational costs.

In contrast, Parker Hannifin offers a diverse range of hydraulic pumps that excel in adaptability and versatility. Their products are engineered to meet specific application requirements, making them suitable for everything from mobile machinery to industrial systems. Eaton, on the other hand, focuses on innovation, providing pumps with integrated smart technology that enhances system monitoring and control, ensuring optimal performance. This comparative analysis highlights that while all three brands maintain high standards, each one brings unique strengths that cater to different industry needs, making them essential players in the hydraulic pump market.

Performance Metrics: What Makes Hydraulic Pumps Efficient?

When it comes to evaluating the efficiency of hydraulic pumps, performance metrics play a crucial role. Key indicators such as volumetric efficiency, mechanical efficiency, and overall efficiency help to determine how effectively a pump converts input energy into hydraulic energy. According to the Hydraulic Institute, the average volumetric efficiency for a well-optimized hydraulic pump can range from 85% to 95%. This metric reflects the pump's ability to move fluid effectively without significant losses due to leakage or cavitation.

Another critical aspect is mechanical efficiency, which focuses on the internal friction and wear that can detract from performance. Industry reports indicate that high-quality hydraulic pumps can achieve mechanical efficiencies upwards of 90%, suggesting that selecting the right materials and design can drastically improve longevity and reduce operational costs. Additionally, overall efficiency, which combines both volumetric and mechanical efficiency, is essential for assessing a pump's effectiveness in real-world applications. According to a study by the International Society for Hydraulic Engineering, the most efficient hydraulic systems can operate with an overall efficiency of around 85% or greater, emphasizing the importance of regular maintenance and the selection of high-performance models for optimal operations.

Top 10 Hydraulic Pumps Efficiency Comparison

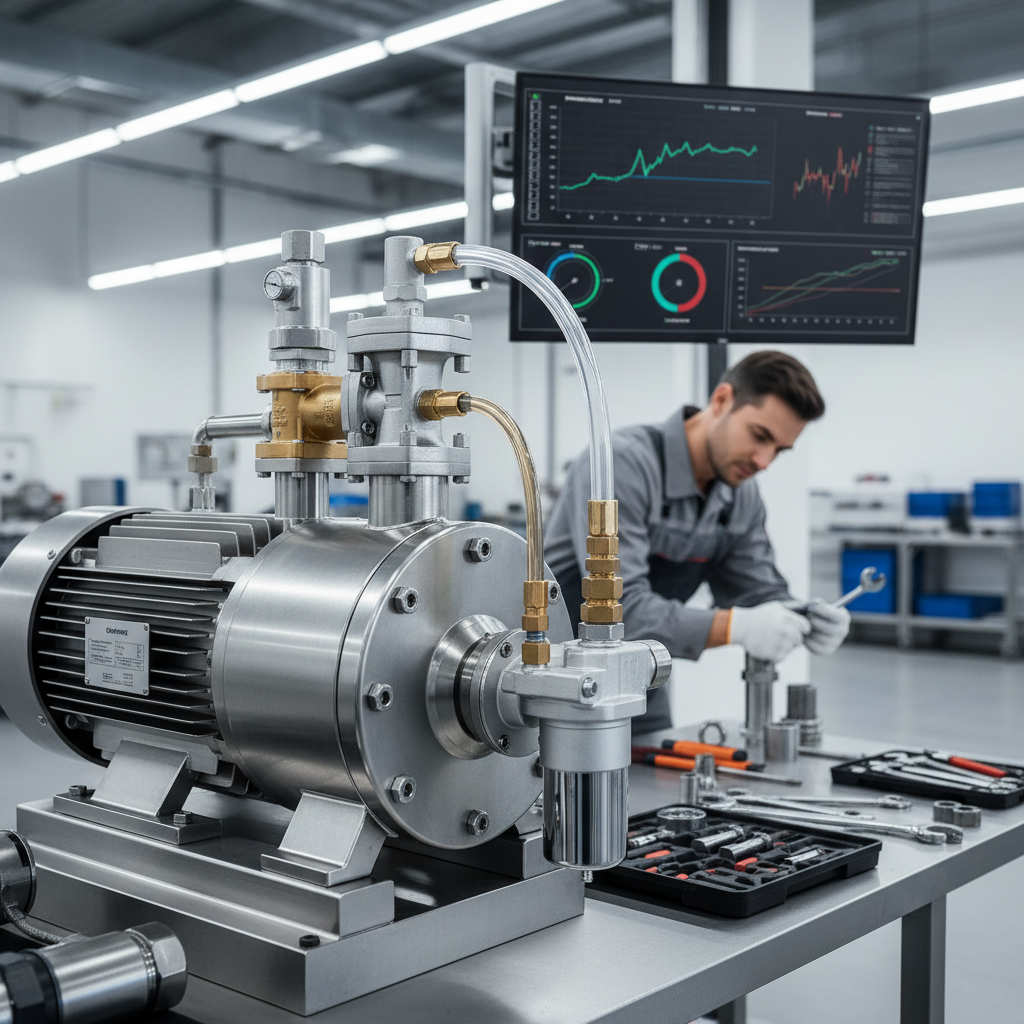

Maintenance Tips for Optimal Hydraulic Pump Functionality

Maintaining optimal functionality in hydraulic pumps is crucial for maximizing performance and efficiency. Regular maintenance can reduce equipment downtime by up to 30%, a significant factor considering the cost implications of unplanned outages. A study by the Hydraulic Institute reveals that nearly 80% of hydraulic pump failures are attributed to inadequate maintenance practices. Therefore, implementing a robust maintenance schedule that includes regular inspections, fluid checks, and component replacements is essential.

One effective maintenance tip is to routinely monitor the hydraulic fluid's cleanliness and viscosity. The ISO 4406 standard classifies fluid cleanliness and recommends maintaining a level of 18/16/13 for most hydraulic systems to enhance reliability and lifespan. Additionally, conducting regular thermal imaging scans can help identify potential overheating issues or abnormal wear in pump components before they escalate into serious failures. Ensuring that filters are changed and that seals are checked for wear can further extend the life of hydraulic pumps, ultimately leading to improved overall operational efficiency and reduced total cost of ownership.

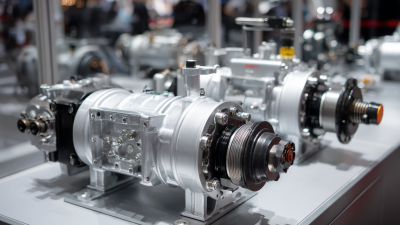

Latest Innovations in Hydraulic Pump Technology and Design

The field of hydraulic pump technology has witnessed significant advancements in recent years, focusing on improving performance and efficiency. Innovations such as variable displacement pumps and smart control systems have become increasingly popular, allowing for enhanced energy savings and reduced operational costs. These technologies enable pumps to adapt their output based on real-time demands, ensuring that they operate only at necessary capacity.

Tip: When selecting a hydraulic pump, consider options that incorporate digital monitoring systems. These can provide real-time feedback on efficiency and performance, helping to identify maintenance needs before they lead to failures.

Additionally, advancements in materials science have resulted in stronger, lighter components that enhance the durability and lifespan of hydraulic pumps. Composite materials and advanced seals not only improve performance but also contribute to reducing the environmental impact of hydraulic systems.

Tip: Regularly examine the materials used in your hydraulic system; choosing pumps made with advanced materials can minimize wear and extend the life of your equipment, ultimately saving costs in the long run.

Top 10 Hydraulic Pumps: Performance and Efficiency

| Pump Type | Flow Rate (L/min) | Pressure (bar) | Efficiency (%) | Key Innovations |

|---|---|---|---|---|

| Gear Pump | 50 | 200 | 90 | Compact design, High pressure capabilities |

| Piston Pump | 75 | 250 | 92 | Variable displacement, Reduced energy consumption |

| Vane Pump | 40 | 180 | 89 | Self-priming, Quiet operation |

| Diaphragm Pump | 30 | 150 | 85 | Leverage fluid pressure, Sanitary applications |

| Screw Pump | 60 | 220 | 88 | Low pulsation flow, High seal integrity |

| Electrical Pump | 55 | 200 | 91 | Energy-efficient, Smart control systems |

| Hydraulic Gear Pump | 45 | 175 | 87 | Compact and lightweight, High efficiency |

| Multi-Stage Pump | 70 | 300 | 93 | High pressure and flow control, Robust design |

| Variable Displacement Pump | 80 | 250 | 94 | Adaptive control, Significant energy savings |

| Low Noise Pump | 65 | 220 | 90 | Quiet operation, Eco-friendly materials |

Related Posts

-

What is Hydraulic Pump Repair and Why It Matters for Industry Efficiency

-

Ultimate Checklist for Efficient Hydraulic Pump Repair Maintenance

-

Unveiling Trends in Electric Hydraulic Pump Demand at China's 138th Canton Fair 2025: Market Insights and Growth Forecasts

-

2025 Top 5 Hydraulic Pumps and Motors You Need for Optimal Performance

-

7 Compelling Reasons to Choose Fluid Power Hydraulics for Your Industrial Needs

-

Unlocking Efficiency: The Ultimate Guide to Hydraulic Power Packs for Modern Applications

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us