How to Optimize Your Hydraulic System for Better Performance?

In the world of machinery, the hydraulic system plays a vital role in operational efficiency. According to a report by the National Fluid Power Association, hydraulic systems account for up to 25% of energy consumption in industrial settings. Optimizing these systems is crucial. Even slight improvements can lead to significant energy savings and enhanced performance.

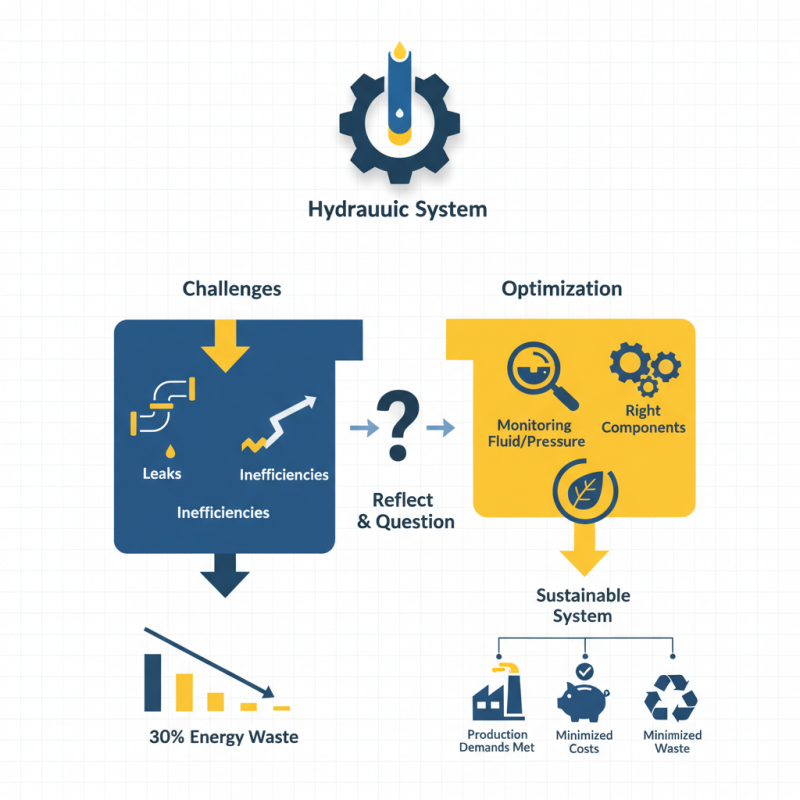

Many companies face challenges when it comes to their hydraulic systems. Issues like leaks and inefficiencies can reduce their overall effectiveness. In fact, a study revealed that poorly maintained hydraulic systems can waste up to 30% of their energy output. This stark reality highlights the importance of being proactive in system management.

Reflections on current practices are essential. Are you regularly monitoring fluid levels and system pressures? Are you using the right components for your specific applications? These questions can drive better performance and reliability. The goal should be to create a sustainable hydraulic system that not only meets production demands but also minimizes costs and waste.

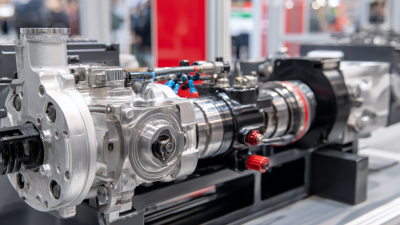

Understanding Your Hydraulic System Components and Their Functions

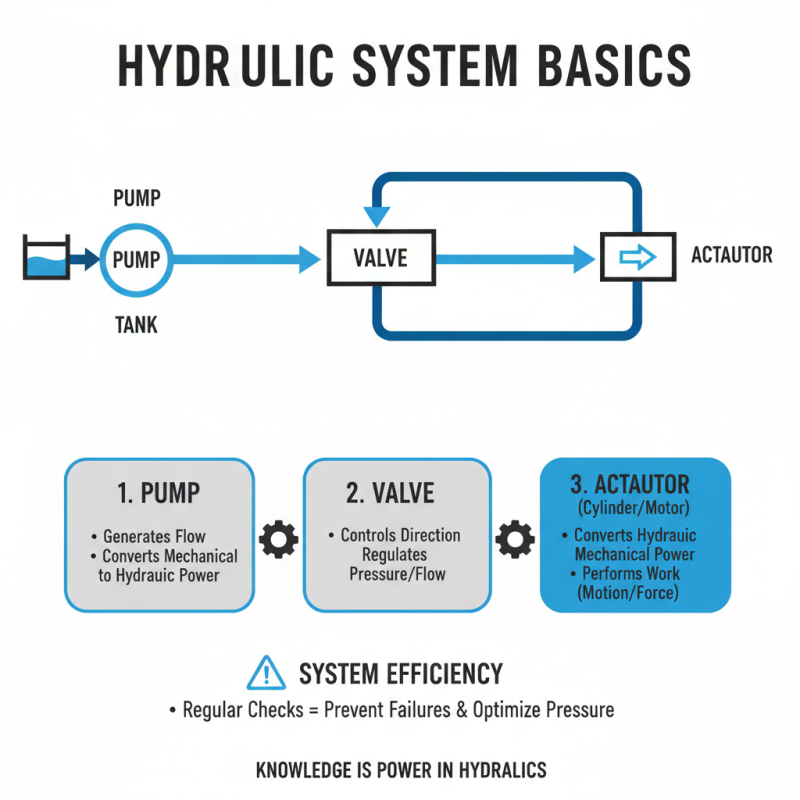

Understanding your hydraulic system components is crucial for optimizing performance. Each part plays a role in the system’s efficiency. Pumps generate flow, while valves control that flow. Understanding their functions helps identify potential issues. For instance, if a pump fails, it can lead to reduced pressure. Regular checks can prevent these failures.

Hoses and fittings may seem like minor components, but they are vital. A small leak can waste resources and impair functionality. Inspecting these parts frequently is important. Also, filters are often overlooked, yet they keep contaminants at bay. Clogged filters can cause a drop in performance.

Balancing these components may not always be straightforward. You might find that one part works perfectly while another doesn't. It's an ongoing challenge. Sometimes, it requires trial and error. Observing the system's behavior can lead to improved decisions. Embrace the complexity of your hydraulic system. It leads to better performance over time.

Evaluating System Efficiency: Identifying Bottlenecks and Weak Points

Evaluating the efficiency of a hydraulic system is crucial for optimal performance. Begin with a comprehensive system analysis. Look for fluctuations in pressure and flow rates. These can reveal inefficiencies. A simple gauge can help track these metrics over time. Unexpected drops in pressure often indicate leaks or blockages.

Next, focus on connecting components. Hoses and fittings can be weak points. Inspect them regularly for wear and tear. Even a small crack can reduce efficiency dramatically. Sometimes, repositioning hoses can improve flow.

Consider the fluid itself. Is it clean and properly maintained? Contaminated fluid can lead to unexpected breakdowns. Filters should be replaced routinely. Regular maintenance checks can prevent minor issues from escalating. Identifying these bottlenecks takes effort but can lead to significant improvements. Reflect on your system's layout and functionality often.

Implementing Proper Maintenance Practices for Hydraulic Systems

Proper maintenance of hydraulic systems is crucial for optimal performance. Regularly inspect hydraulic fluid levels. Low fluid can lead to pump failure. Keep an eye on hoses and connections too. A small leak can escalate into a major issue. Replace any damaged components immediately. This proactive approach prevents bigger problems down the line.

Contributing factors often go unnoticed. For instance, operating pressure should be monitored frequently. An imbalance can stress the system. Regular filter changes are also essential. Dirty filters can restrict flow, reducing efficiency. Yet, many operators overlook this simple task. Sometimes, it’s easy to forget that neglect can lead to costly repairs.

Training staff on maintenance practices is vital. Knowledge gaps may exist among team members. Encourage open discussions about common issues. Reflection on past failures helps improve future performance. A culture of proactive maintenance can make a significant difference in hydraulic system longevity and reliability.

Choosing the Right Hydraulic Fluids for Optimal Performance

Choosing the right hydraulic fluid is crucial for system efficiency. Different fluids have varying viscosities and properties. These differences affect performance under varying temperatures and pressures. Selecting an appropriate fluid can enhance lubrication and reduce wear on components.

Consider the operating environment when selecting hydraulic fluids. High temperatures can thin fluids, leading to leaks. Cold temperatures can thicken them, causing sluggish operation. Always check the fluid's temperature range before use. It is also essential to evaluate the fluid's compatibility with system materials to avoid degradation.

Regularly monitoring fluid condition is vital. Fluid contamination can degrade performance over time. Sediments and moisture can lead to corrosion and efficiency loss. Implementing a routine inspection and filtration system can improve overall operations. Ignoring fluid quality can result in costly repairs.

Hydraulic Fluid Viscosity Comparison for Optimal Performance

This chart compares the viscosity of different hydraulic fluids at varying temperatures. Selecting the right fluid can significantly enhance the performance of your hydraulic system.

Upgrading System Components for Enhanced Reliability and Efficiency

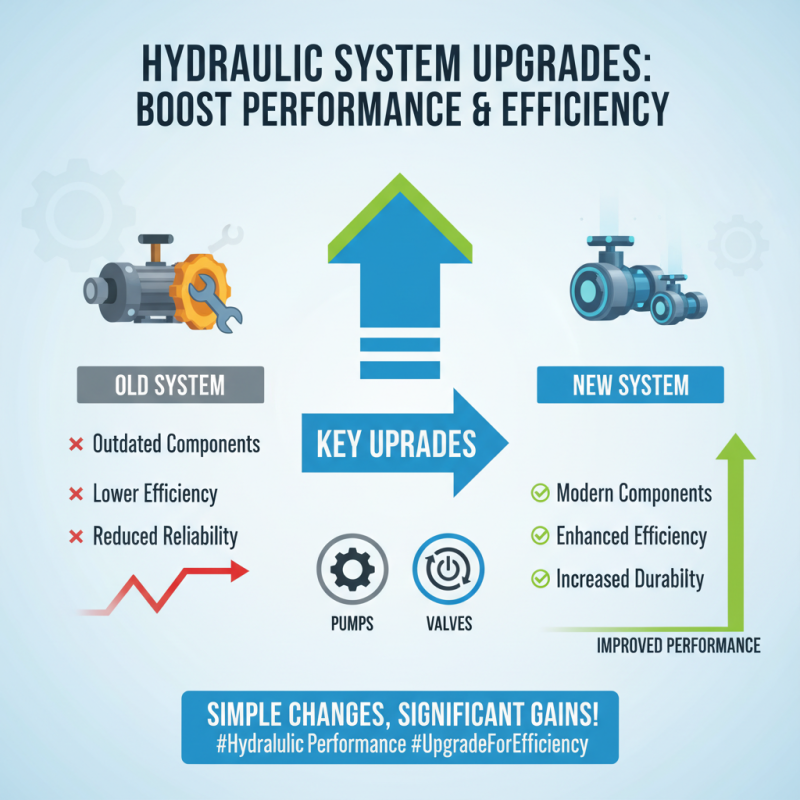

Upgrading system components is crucial for improving hydraulic performance. Many users overlook simple upgrades that can enhance reliability and efficiency. For instance, replacing outdated pumps or valves often leads to immediate gains. Newer components typically offer better energy efficiency and increased durability.

Regular inspection is also essential. Sometimes, a small leak can significantly affect system performance. Identifying these leaks early can save both time and money. Consider the condition of hoses and seals as well. Old or worn parts might be easy to ignore, but they impact overall functionality.

Don’t forget about the hydraulic fluid itself. It plays a vital role in system efficiency. Contaminated fluid can cause various issues, from overheating to component failure. Monitoring fluid quality should be part of routine maintenance. It's easy to get complacent, but staying proactive reduces unexpected downtime. Remember, the smallest changes can lead to remarkable improvements.

Related Posts

-

Top Strategies for Optimizing Hydraulic System Efficiency

-

How to Choose the Right Hydraulic Pumps and Motors for Your Industrial Needs

-

2026 Top Air Hydraulic Pump Reviews and Buying Guide?

-

The Essential Guide to Choosing the Right Hydraulic Oil for Optimal Machinery Performance

-

How to Optimize the Performance of a Hydraulic Gear Pump

-

Exploring Hydraulic Pumps and Motors Innovations at the 138th Canton Fair 2025: Industry Insights

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us