How to Optimize Your Operations with Innovative Hydraulic Solutions

In today’s competitive landscape, optimizing operations is essential for businesses striving for efficiency and sustainability. Innovative hydraulic solutions play a crucial role in enhancing productivity across various industries. According to a recent report by MarketsandMarkets, the global hydraulic systems market is projected to reach $55.4 billion by 2025, growing at a CAGR of 4.1%. This growth is driven by the rising demand for energy-efficient systems and automation, reshaping how companies incorporate hydraulic technology into their processes. By embracing advanced hydraulic solutions, organizations can streamline operations, reduce downtime, and lower maintenance costs, leading to significant improvements in overall performance. This article aims to explore effective strategies for leveraging these innovative hydraulic solutions to optimize operational efficiency and gain a competitive edge.

Understanding Hydraulic Solutions: Key Concepts and Innovations

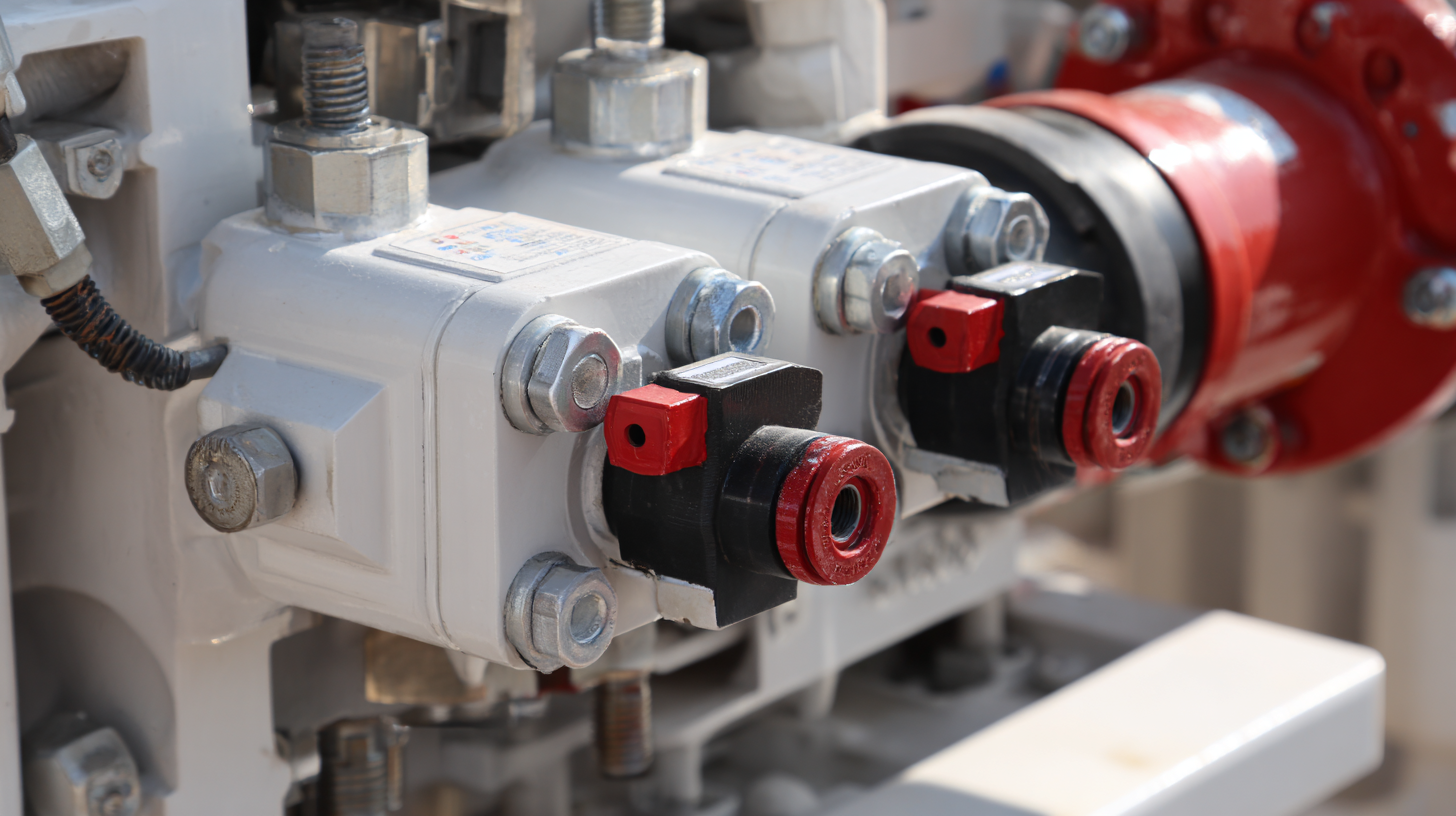

Hydraulic solutions have become essential for optimizing operations across various industries, particularly due to their efficiency and effectiveness in handling heavy loads. Understanding the key concepts behind hydraulic systems—such as pressure, flow, and force—is crucial for leveraging their full potential.

At the heart of these systems lies the hydraulic fluid, which transmits power through pressurized channels. This fluid dynamics allows for precise control over machinery, enabling operations that require significant force with minimal energy expenditure.

Innovative advancements in hydraulic technology have introduced smart systems equipped with sensors and automation features. These enhancements allow for real-time monitoring and adjustments, which increase operational efficiency and reduce downtime. For instance, modern hydraulic systems can detect leaks or inefficiencies, automatically adjust pressure levels, and optimize power consumption.

As industries increasingly prioritize sustainability, the development of eco-friendly hydraulic fluids and energy-efficient designs further underscore the evolution of hydraulic solutions. Understanding these innovations is vital for organizations looking to stay competitive and improve their operational performance.

Evaluating Your Current Operations for Hydraulic Optimization Opportunities

To effectively optimize your operations using innovative hydraulic solutions, the first step is to evaluate your current hydraulic system's performance. According to a report from the International Fluid Power Society, inefficient hydraulic systems can lead to a 30% increase in operating costs. By analyzing each component of your hydraulic system, including pumps, valves, and hoses, you can identify potential inefficiencies, such as pressure drops or excessive leakage that may be costing your operations both time and money.

Additionally, employing data analytics tools can provide valuable insights into your hydraulic operations. A study by the National Fluid Power Association revealed that companies implementing predictive maintenance in their hydraulic systems reported a 25% reduction in downtime and a significant improvement in equipment reliability. By leveraging these analytics, you can proactively address issues before they escalate, streamline your operations, and ultimately enhance productivity. Ensuring your hydraulic infrastructure is up-to-date with the latest technologies further allows for scalability and integration with other automated systems in your facility.

| Operating Area | Current Hydraulic System | Optimization Opportunities | Expected Benefits |

|---|---|---|---|

| Manufacturing | Standard hydraulic presses | Implementing variable speed drives | Reduced energy consumption, improved cycle times |

| Logistics | Conventional hydraulic lifts | Transitioning to smart hydraulic systems | Improved responsiveness, decreased downtime |

| Agriculture | Hydraulic tractors with basic control | Adopting precision agriculture tools | Enhanced efficiency, better yield management |

| Construction | Traditional hydraulic excavators | Incorporating advanced fluid technology | Enhanced performance, reduced maintenance costs |

| Mining | Basic hydraulic drills | Utilizing automated hydraulic systems | Increased safety, improved production rates |

Implementing Advanced Hydraulic Technologies for Enhanced Efficiency

Implementing advanced hydraulic technologies can significantly enhance operational efficiency across various industries, including manufacturing, construction, and agriculture. According to a report by the International Fluid Power Society, businesses that adopted innovative hydraulic solutions experienced a productivity increase of up to 30%. This can be attributed to improved system reliability and reduced downtime, both critical factors in maintaining a competitive edge in today’s fast-paced markets.

Consider these tips to optimize your operations:

- First, invest in variable speed pumps, which can adjust flow rates according to actual demand, leading to energy savings of approximately 25% compared to traditional fixed-speed systems.

- Second, incorporate IoT-enabled hydraulic systems, which provide real-time monitoring and predictive maintenance capabilities, reducing unexpected failures and extending equipment life.

- Lastly, train your workforce in the latest hydraulic technologies to ensure effective implementation and maintenance—companies with skilled staff are 40% more efficient in system operation.

Embracing these advanced hydraulic solutions not only boosts efficiency but also positions your organization to respond swiftly to market changes, ultimately paving the way for sustainable growth.

Training Your Team on Best Practices in Hydraulic Operations

Training your team on best practices in hydraulic operations is essential for optimizing your organization's performance. A well-trained workforce not only enhances operational efficiency but also reduces the risk of accidents and equipment failures.

It is vital to incorporate hands-on training sessions, where team members can engage with hydraulic systems in a controlled environment. This practical approach allows employees to understand the intricacies of hydraulic components, leading to improved troubleshooting skills and maintenance practices.

Furthermore, fostering a culture of continuous learning is crucial. Encourage your team to stay updated with the latest advancements in hydraulic technology and techniques. Regular workshops or seminars featuring industry experts can provide valuable insights into innovative solutions and best practices.

By empowering your team with knowledge, you're not just enhancing their skills but also promoting proactive problem-solving approaches that can significantly impact your operational success. Investing in thorough training ensures that your personnel are equipped to handle challenges effectively, ultimately optimizing your hydraulic operations.

Measuring and Analyzing Performance Improvements Post-Implementation

In the pursuit of optimizing operations through innovative hydraulic solutions, measuring and analyzing performance improvements post-implementation is essential. After implementing new hydraulic technologies, organizations should establish key performance indicators (KPIs) that can effectively gauge efficiency, productivity, and cost savings. These KPIs might include metrics such as cycle time reduction, energy consumption, and maintenance frequency. By collecting data on these indicators before and after the hydraulic system upgrade, companies can gain quantitative insights into the impact of the changes made.

Furthermore, using advanced analytics tools can deepen the analysis, allowing for a more nuanced understanding of how operations have improved. For instance, predictive analytics can identify patterns in equipment performance and reveal areas for further optimization. Additionally, employee feedback and qualitative assessments can complement the quantitative data, providing a holistic view of the operational changes. This comprehensive analysis not only validates the success of the innovative hydraulic solutions but also guides future investments and improvements, ensuring that organizations remain competitive and agile in a fast-evolving industry.

Related Posts

-

Essential Pneumatic Hydraulic Maintenance Checklist for Optimal Performance

-

7 Compelling Reasons to Choose Fluid Power Hydraulics for Your Industrial Needs

-

Innovative Solutions for Fluid Power Hydraulics Efficiency

-

Understanding Common Issues with Hydraulic Pumps and Motors in Industrial Applications

-

10 Essential Tips for Mastering Pneumatic and Hydraulic Systems

-

Pneumatic Hydraulics Versus Traditional Hydraulics A Comprehensive Comparison of Efficiency and Performance

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us