How to Optimize the Performance of Your Hydraulic Pump Motor

In today’s industrial landscape, optimizing the performance of hydraulic pump motors is critical for enhancing operational efficiency and reducing costs. According to a report by MarketsandMarkets, the hydraulic equipment market is projected to reach $48.48 billion by 2025, emphasizing the growing reliance on hydraulic systems across various sectors such as construction, manufacturing, and agriculture. Efficient hydraulic pump motors are essential components, as they directly influence the system's overall productivity and energy consumption. Studies show that optimizing motor performance can lead to a 10-20% reduction in energy costs, significantly impacting the bottom line. As industries confront increasing energy prices and the need for sustainable practices, understanding how to enhance the functionality of hydraulic pump motors becomes paramount for staying competitive in the market.

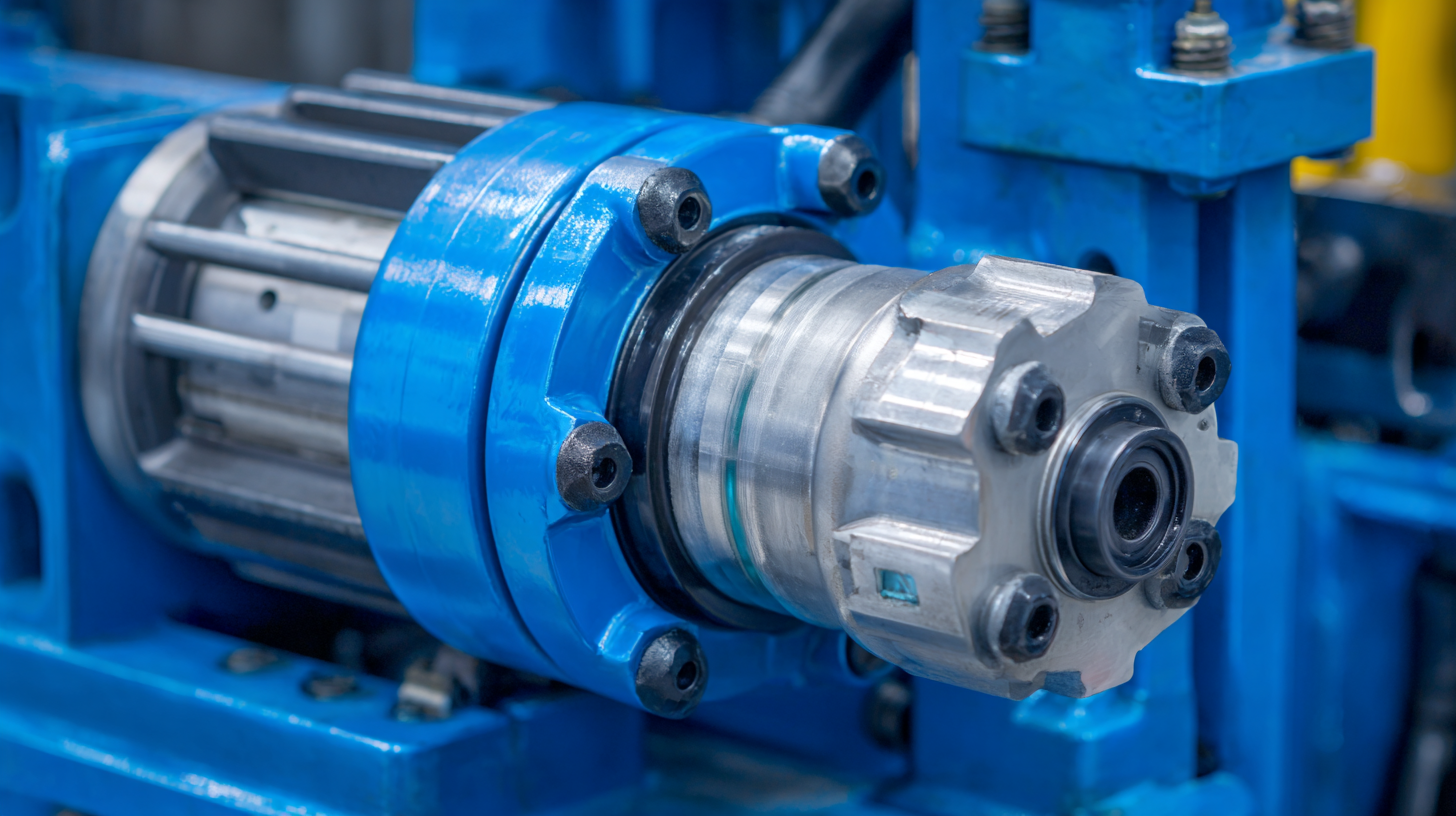

Understanding the Basics of Hydraulic Pump Motors

Hydraulic pump motors are vital components in hydraulic systems, converting hydraulic energy into mechanical power to perform various tasks. Understanding their operation is essential for optimizing performance and ensuring system efficiency. According to a report by the Hydraulic Institute, nearly 80% of hydraulic system failures are attributed to improper motor selection, emphasizing the importance of understanding the basics before installation or maintenance.

To start, it's crucial to know the different types of hydraulic pump motors, such as gear, vane, and piston motors, each with its unique characteristics and applications. For instance, gear motors are renowned for their simplicity and durability, while piston motors offer higher efficiency and power density. A study by the American Society of Mechanical Engineers notes that selecting the right motor type can improve energy efficiency by up to 30%, showcasing the impact of informed choices.

Tip: Regular maintenance, including checking fluid levels and filter conditions, can prolong the lifespan of your hydraulic pump motor. Additionally, monitoring temperature and vibration levels can help identify potential issues before they escalate.

Tip: It’s also beneficial to ensure that the motor is adequately matched to the pump's capacity. A mismatch can lead to overheating and increased energy consumption, adversely affecting overall system performance.

Factors Affecting Hydraulic Pump Motor Performance

When it comes to optimizing the performance of hydraulic pump motors, understanding the key factors that impact their efficiency is crucial. One primary aspect is the hydraulic fluid properties, including viscosity and temperature. According to the Hydraulic Institute, an optimal viscosity range for hydraulic oils is typically between 15 to 68 centistokes, depending on the operational conditions. If the viscosity is too high, it can cause excessive energy loss through internal friction, while too low can lead to inadequate lubrication.

Another significant factor is the motor speed and load conditions. Data from the International Organization for Standardization (ISO) indicates that hydraulic pump motors operate most efficiently at specific RPMs, typically between 1,200 to 1,800 RPM for many applications. Operating outside this range can result in increased wear and energy consumption. Additionally, considering the system design, including pipe diameter and length, can greatly affect hydraulic flow and pressure drops, directly influencing motor performance. By paying close attention to these variables, users can significantly enhance the efficiency and lifespan of their hydraulic pump motors.

Best Practices for Maintaining Your Hydraulic Pump Motor

Maintaining a hydraulic pump motor is crucial for ensuring optimal performance and longevity. Regular maintenance can significantly reduce the risk of unexpected downtime and costly repairs. According to a report by the International Hydraulic Manufacturers Association (IHMA), more than 30% of hydraulic system failures are attributed to inadequate maintenance. Implementing a consistent maintenance schedule, which includes fluid checks, filter replacements, and inspections of seals and hoses, can help mitigate these issues.

Another best practice is to monitor operating temperatures and pressures. The American Society of Mechanical Engineers (ASME) suggests that maintaining fluid temperature within the recommended range can enhance the efficiency of hydraulic systems. Elevated temperatures can lead to fluid degradation, which negatively affects performance and can even shorten the lifespan of the hydraulic pump motor. By utilizing thermal imaging technology, operators can detect overheating components early on and take corrective actions to prevent further issues. Regular training for staff on maintenance protocols and the use of advanced monitoring systems can ultimately lead to improved operational efficiency and reduced maintenance costs.

Hydraulic Pump Motor Performance Optimization

This chart illustrates the maintenance practices and their corresponding impact on the efficiency of hydraulic pump motors. The data reflects the percentage improvement in performance based on different maintenance activities.

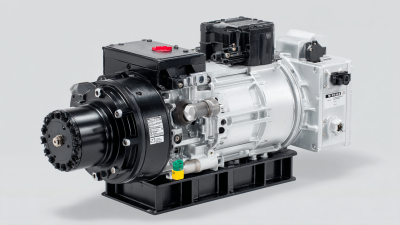

Upgrading Components for Enhanced Efficiency

Upgrading components in your hydraulic pump motor can significantly enhance its efficiency and overall performance. One of the critical areas to consider is the motor itself. Incorporating variable frequency drives (VFD) not only ensures better control over speed and torque but also reduces energy consumption. According to recent studies, implementing VFDs can lead to energy savings of up to 60% in hydraulic applications.

Another vital upgrade involves examining the hydraulic fluid used. Modern biogas production technologies emphasize the importance of utilizing high-quality lubricants to lower friction and maximize efficiency. Advances in fluid formulation can provide better thermal stability and reduce wear on system components, greatly extending the lifespan of the motor.

**Tips**: Regularly maintain your hydraulic system by checking for leaks and ensuring proper fluid levels. Additionally, consider retrofitting with custom-designed components that match your specific system requirements for optimal performance. Upgrading the electrical components and sensors not only adds to reliability but also facilitates the integration of smart features that can predict maintenance needs and further optimize performance.

Troubleshooting Common Issues in Hydraulic Pump Motors

When troubleshooting common issues in hydraulic pump motors, it is essential to understand the underlying causes of performance degradation. According to a report from the Hydraulic Institute, approximately 30% of hydraulic pump failures are linked to inadequate electrical supply or incorrect motor sizing. Therefore, ensuring that your motor is correctly matched to the pump’s specifications is crucial. Regular maintenance checks for electrical connections, voltage stability, and motor insulation can prevent most electrical issues.

When troubleshooting common issues in hydraulic pump motors, it is essential to understand the underlying causes of performance degradation. According to a report from the Hydraulic Institute, approximately 30% of hydraulic pump failures are linked to inadequate electrical supply or incorrect motor sizing. Therefore, ensuring that your motor is correctly matched to the pump’s specifications is crucial. Regular maintenance checks for electrical connections, voltage stability, and motor insulation can prevent most electrical issues.

Another common problem is fluid contamination, which can significantly compromise operational efficiency. Recent data from the NFPA indicates that 80% of hydraulic system failures are attributed to fluid contamination. Implementing a strict fluid management protocol—such as regular fluid analysis and using effective filtration systems—can mitigate these risks.

Tips: To maintain optimal performance, consider scheduling routine inspections of hydraulic fluid quality and replacing filters as needed. Additionally, it’s beneficial to train operators to recognize early signs of potential issues, such as unusual vibrations or noise, which can lead to more significant problems if unaddressed. Proper training and awareness can greatly enhance the lifespan and productivity of hydraulic pump motors.

Related Posts

-

How to Optimize Air Hydraulic Pump Performance for Maximum Efficiency

-

7 Best Hydraulic Motors for Efficient Energy Solutions in 2024

-

What is Hydraulic Pump Repair and Why It Matters for Industry Efficiency

-

7 Compelling Reasons to Choose Fluid Power Hydraulics for Your Industrial Needs

-

How to Choose the Right Gas Powered Hydraulic Pump for Your Needs

-

10 Best Hydraulic Cylinder Parts You Should Know

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us