How to Optimize Pneumatic Hydraulic Systems for Enhanced Performance

In today's industrial landscape, optimizing pneumatic hydraulic systems is crucial for enhancing performance and efficiency. These systems, which combine the benefits of both pneumatic and hydraulic technologies, are integral to a wide range of applications in manufacturing, construction, and transportation. As industries seek to maximize productivity while minimizing downtime and energy consumption, understanding how to effectively optimize pneumatic hydraulic systems becomes essential.

This guide will delve into key strategies and techniques for improving the performance of these systems, highlighting the importance of proper maintenance, component selection, and system integration. By implementing these optimization methods, businesses can achieve not only better operational efficiency but also increased reliability and longevity of their equipment in various demanding environments.

Understanding Pneumatic Hydraulic System Components for Optimization

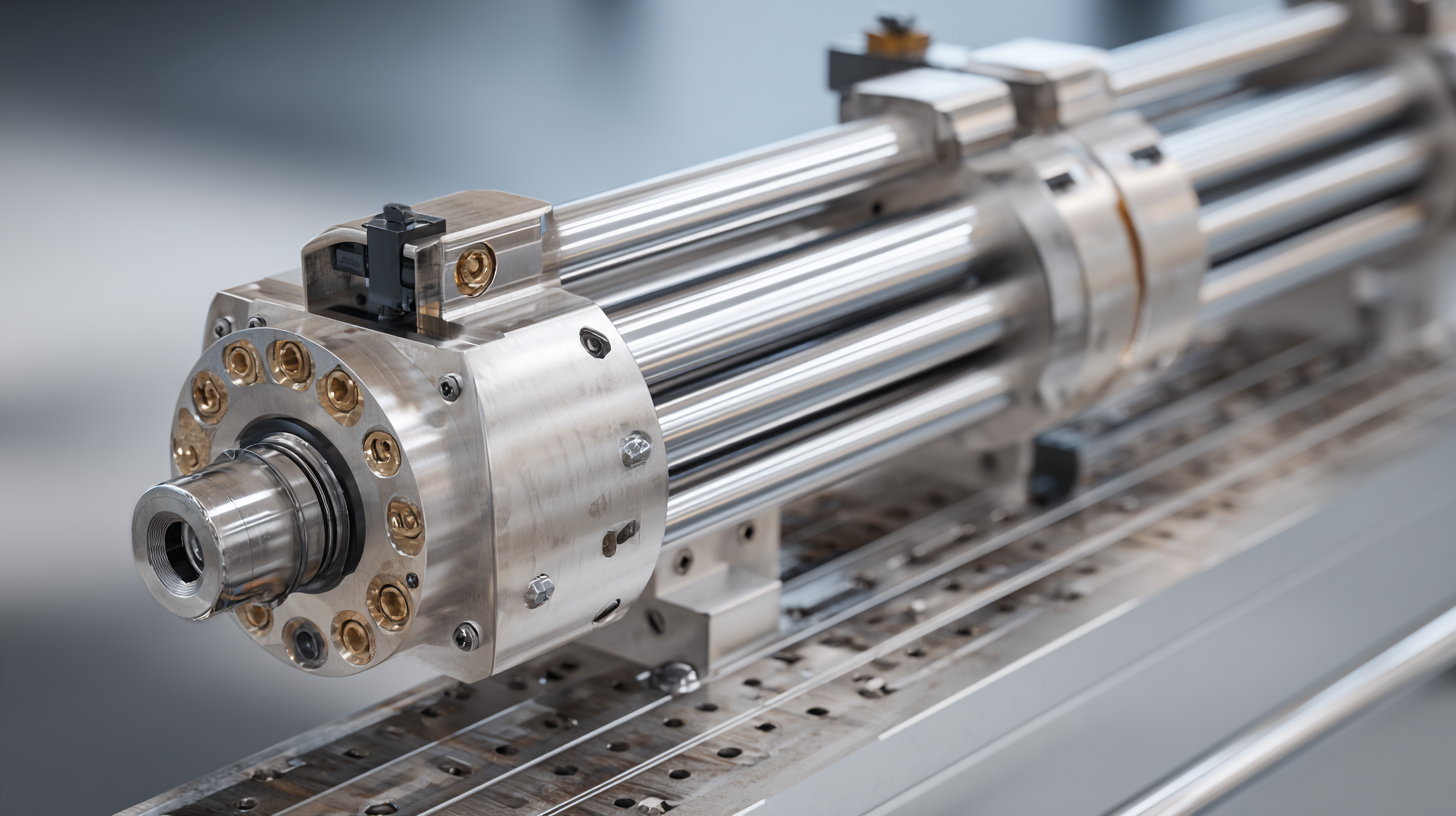

In optimizing pneumatic hydraulic systems, a thorough understanding of their components is essential for enhancing overall performance. Key components include the pump, actuators, valves, and reservoirs, each playing a vital role in system functionality. The pump is responsible for generating the necessary pressure, and selecting the right type—be it piston, gear, or diaphragm—can significantly affect efficiency and responsiveness.

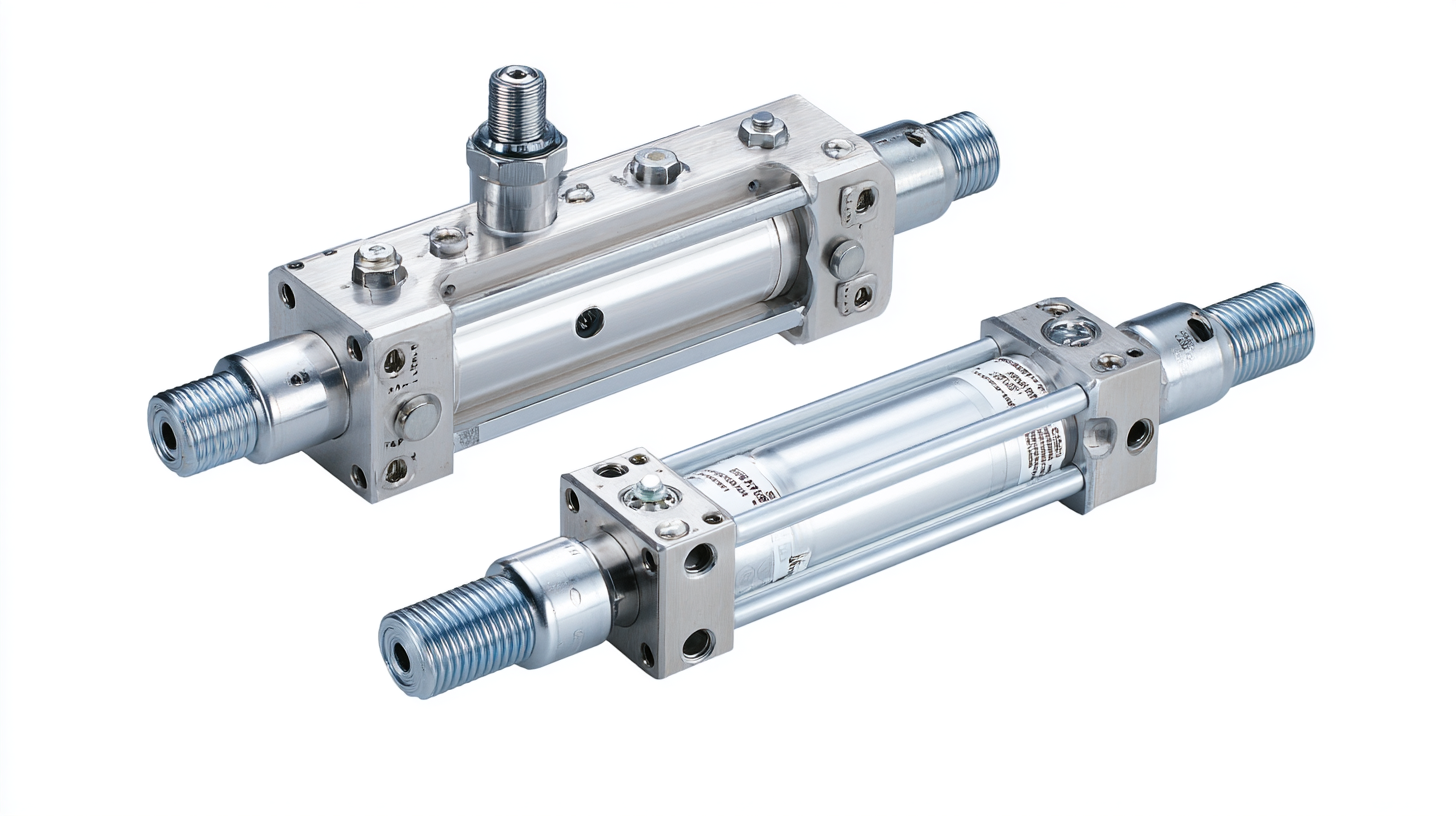

Actuators, which convert fluid energy into mechanical motion, need to be carefully matched to the system's demands to ensure optimal output and minimal energy waste.

Actuators, which convert fluid energy into mechanical motion, need to be carefully matched to the system's demands to ensure optimal output and minimal energy waste.

Valves also serve a critical function in controlling fluid flow and pressure. By implementing high-quality, responsive valves, one can achieve precise control over the system’s operation. Regular maintenance of these components, including checking for leaks and wear, is fundamental to prevent performance degradation. Additionally, optimizing reservoir design to enhance fluid storage and ensure proper fluid filtration can lead to more reliable operations. By focusing on these components, one can create a more efficient and responsive pneumatic hydraulic system, ultimately extending its lifespan and performance capabilities.

Identifying Key Performance Metrics to Enhance System Efficiency

To enhance the efficiency of pneumatic hydraulic systems, it is crucial to identify and monitor key performance metrics. These metrics can include parameters such as pressure levels, flow rates, and response times. By establishing baseline values for these metrics, operators can quickly detect deviations that may indicate inefficiencies or potential failures within the system. Regular monitoring allows for timely adjustments, ultimately leading to improved system reliability and reduced downtime.

Another important performance metric is energy consumption, which directly impacts operational costs. By analyzing energy usage patterns, companies can pinpoint areas where energy is wasted and implement strategies to minimize consumption. Additionally, measuring system responsiveness in real-time can help in fine-tuning the system to ensure optimal performance. By focusing on these key metrics, businesses can not only enhance the functionality of their pneumatic hydraulic systems but also achieve a more sustainable and cost-effective operation.

Implementing Regular Maintenance Routines to Ensure Optimal Functioning

Regular maintenance routines are crucial in optimizing pneumatic and hydraulic systems to ensure they function at peak performance. According to data from the International Fluid Power Society, routine maintenance can reduce the likelihood of system failures by up to 50%. By implementing a structured maintenance schedule, operators can identify wear and tear before it leads to significant issues, thus minimizing downtime and increasing system reliability.

Key maintenance activities include regular inspection of seals and hoses, checking fluid levels and quality, and ensuring that all components are free from contamination. The National Fluid Power Association recommends that systems using hydraulic fluids should have their fluids and filters replaced at least every 1,500 operating hours or annually. This proactive approach not only enhances efficiency but also prolongs the lifespan of the equipment.

Additionally, investing in training for staff on proper maintenance procedures can further optimize operational effectiveness, according to the Fluid Power Educational Foundation, which found that systems maintained by trained personnel perform 20% better on average.

Leveraging Advanced Control Technologies for Improved Responsiveness

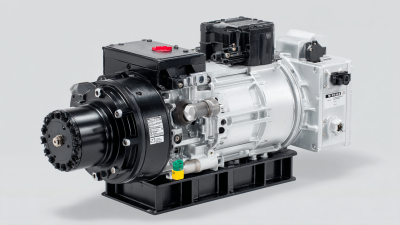

Optimizing pneumatic hydraulic systems for enhanced performance requires the implementation of advanced control technologies that foster improved responsiveness. The integration of artificial intelligence (AI) into these systems can significantly enhance real-time monitoring and control capabilities, allowing for more precise management of fluid dynamics and pressure. By leveraging AI algorithms, engineers can develop predictive maintenance models and adapt system controls dynamically based on operational conditions, leading to increased efficiency and reduced downtime.

Furthermore, advanced sensor-based interfaces enable seamless communication between humans and machines in pneumatic hydraulic systems, making it easier to adjust parameters in response to immediate feedback. This responsiveness ensures that hydraulic systems can quickly adapt to changes in load and performance requirements, stretching their functional capabilities while maintaining safety and reliability. The convergence of AI and sophisticated human-machine interaction facilitates a more intuitive operational framework, paving the way for smarter, more responsive pneumatic hydraulic systems that meet the demands of modern applications.

How to Optimize Pneumatic Hydraulic Systems for Enhanced Performance - Leveraging Advanced Control Technologies for Improved Responsiveness

| Parameter | Current Value | Optimized Value | Improvement (%) |

|---|---|---|---|

| System Pressure (Bar) | 50 | 70 | 40% |

| Flow Rate (L/min) | 120 | 150 | 25% |

| Actuator Speed (m/s) | 0.5 | 0.75 | 50% |

| Response Time (ms) | 200 | 150 | 25% |

| Energy Consumption (kWh) | 300 | 240 | 20% |

Integrating Energy-Efficient Solutions to Reduce Operational Costs

Integrating energy-efficient solutions into pneumatic hydraulic systems can significantly reduce operational costs while enhancing overall performance. According to a report by the International Energy Agency (IEA), industrial energy efficiency improvements could save industries up to $470 billion annually by 2030. By implementing energy-efficient components, such as variable frequency drives (VFDs) and energy recovery systems, companies can optimize their hydraulic systems to use less power without compromising performance. For example, VFDs can adjust motor speed based on demand, achieving energy savings of up to 30%.

Additionally, incorporating smart control technologies allows for real-time monitoring and adjustments of operational parameters, which further enhances energy efficiency. A study conducted by the Hydraulic Pump and Motor Manufacturer's Association (HPMA) indicates that systems utilizing these advanced controls can reduce energy consumption by as much as 25%. With the rising cost of energy, investing in these innovative solutions not only minimizes expenses but also supports sustainability goals, ultimately leading to a more competitive and eco-friendly operation in the industrial sector.

Related Posts

-

10 Essential Tips for Mastering Pneumatic and Hydraulic Systems

-

Essential Pneumatic Hydraulic Maintenance Checklist for Optimal Performance

-

Pneumatic Hydraulics Versus Traditional Hydraulics A Comprehensive Comparison of Efficiency and Performance

-

10 Best Hydraulic Cylinder Parts You Should Know

-

How to Choose the Right Gas Powered Hydraulic Pump for Your Needs

-

7 Best Hydraulic Motors for Efficient Energy Solutions in 2024

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us