Revolutionizing Hydraulic Systems Trends and Insights at the 138th China Import and Export Fair 2025

The 138th China Import and Export Fair in 2025 is set to showcase groundbreaking advancements in hydraulic systems, a critical component in various industrial applications. As the hydraulic system market continues to expand, with a projected compound annual growth rate (CAGR) of 5.4% from 2020 to 2027 according to a recent industry report by Fortune Business Insights, the importance of innovation and sustainability in design and implementation is becoming increasingly evident. This fair will not only highlight the latest technological developments but also address the challenges faced by manufacturers in integrating eco-friendly practices within hydraulic systems. With the global hydraulic systems market expected to reach USD 60 billion by 2027, the insights gathered during this event will be pivotal for stakeholders aiming to harness new technologies that improve efficiency and reduce environmental impact.

Revolutionizing Hydraulic Systems: Key Innovations Showcased at the 138th China Import and Export Fair

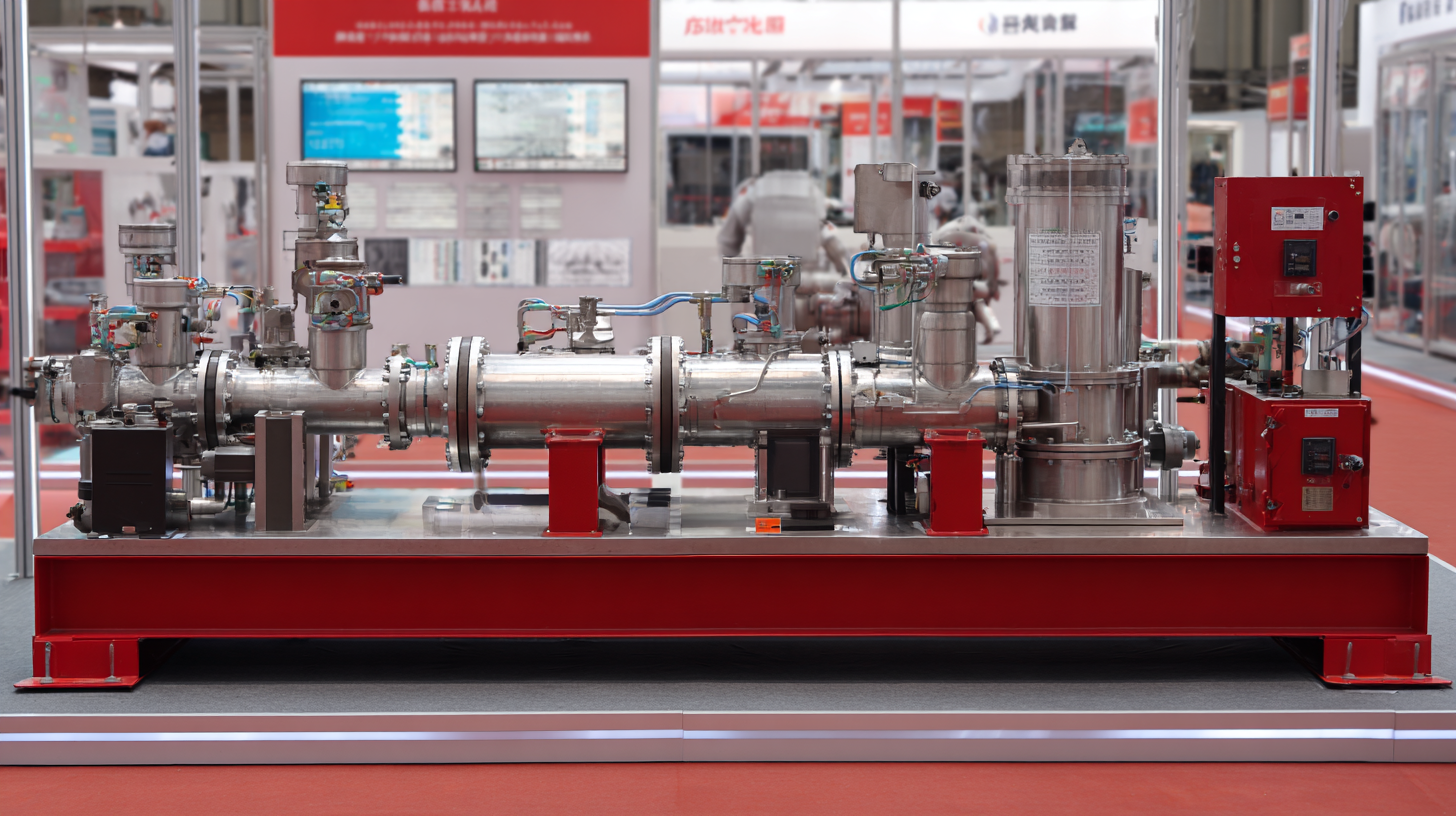

The 138th China Import and Export Fair is set to unveil groundbreaking innovations in hydraulic systems that promise to enhance efficiency and sustainability in various industries. This event provides a unique platform for manufacturers and tech enthusiasts to explore state-of-the-art hydraulic technologies designed to revolutionize the way systems operate. Key innovations include advanced hydraulic pumps and smart control systems that optimize performance while reducing energy consumption.

The 138th China Import and Export Fair is set to unveil groundbreaking innovations in hydraulic systems that promise to enhance efficiency and sustainability in various industries. This event provides a unique platform for manufacturers and tech enthusiasts to explore state-of-the-art hydraulic technologies designed to revolutionize the way systems operate. Key innovations include advanced hydraulic pumps and smart control systems that optimize performance while reducing energy consumption.

Tips for attendees: Engage with exhibitors and ask about the specifics of their technologies. Understanding the application of these innovations in real-world scenarios can provide valuable insights into how they can improve your operations. Additionally, attend workshops and demonstrations to gain hands-on experience with the latest products being showcased.

Moreover, the fair highlights the significance of integrating digital solutions with traditional hydraulic systems. The blend of IoT and automation within hydraulic frameworks exhibits great potential to enhance monitoring and maintenance practices. This integration not only increases system longevity but also sets the stage for predictive maintenance, ultimately driving down costs and minimizing downtime for businesses.

Tips for attendees: Consider networking with experts in the field to learn about best practices in implementing these technologies. Collaborating with industry leaders will help you stay ahead in the rapidly evolving hydraulic landscape.

Emerging Trends in Hydraulic Technology: Predictive Analytics and IoT Integration

At the 138th China Import and Export Fair in 2025, the spotlight will be on emerging trends in hydraulic technology, particularly the integration of predictive analytics and the Internet of Things (IoT). This convergence is set to transform traditional hydraulic systems by enhancing operational efficiency and minimizing downtime. By leveraging predictive analytics, manufacturers can analyze vast data sets to foresee potential system failures and schedule maintenance proactively. This approach not only reduces operational costs but also extends the lifespan of hydraulic systems.

Moreover, the integration of IoT in hydraulic technology allows for real-time monitoring and control. Sensors embedded within hydraulic components can continuously collect data on performance metrics, sending alerts when anomalies are detected. This level of connectivity empowers operators to make informed decisions swiftly, optimizing system performance and ensuring safety. As these technologies evolve, they promise a new era of hydraulic systems that are not only smarter but also more resilient, paving the way for innovative applications across various industries.

Sustainable Practices in Hydraulic Systems: Eco-Friendly Solutions Gaining Ground

At the 138th China Import and Export Fair in 2025, a significant focus will be on sustainable practices in hydraulic systems. As industries worldwide strive to minimize their environmental impact, eco-friendly solutions in hydraulic technology are becoming increasingly vital. Innovations such as biodegradable hydraulic fluids, energy-efficient hydraulic pumps, and smart control systems are emerging as key trends. These advancements not only reduce carbon footprints but also enhance overall system efficiency, making them attractive alternatives for modern enterprises seeking sustainability.

Furthermore, the integration of renewable energy sources into hydraulic systems marks a pivotal shift. Companies are now exploring ways to harness solar and wind power to drive hydraulic operations, thereby decreasing reliance on fossil fuels. This transition not only supports global sustainability goals but also addresses rising energy costs, presenting a dual benefit for manufacturers. By showcasing these eco-friendly solutions at the fair, industry leaders highlight their commitment to environmental stewardship while also paving the way for a more sustainable future in hydraulic systems.

Trends in Sustainable Hydraulic Systems

This bar chart illustrates the growing adoption of eco-friendly solutions in hydraulic systems over recent years. Data reflects the percentage of companies implementing sustainable practices in their hydraulic systems from 2020 to 2025.

Market Insights: Growth Projections for Hydraulic Systems in Asia-Pacific Region

The hydraulic systems market in the Asia-Pacific region is poised for substantial growth, driven by increasing demand across various industries. As of 2018, the global hydraulic cylinder market was valued at $10.94 billion, with projections suggesting it could reach $19.77 billion by 2032, reflecting a compound annual growth rate (CAGR) of 4%. This trend highlights strong investment opportunities, particularly in agricultural sprayers, where the market is expected to hit $7.8 billion by 2032, growing at a CAGR of 6.84% due to the rising need for precision agriculture technologies.

Tips: To capitalize on these trends, businesses should focus on innovation in design and efficiency of hydraulic systems. Additionally, maintaining a keen awareness of regional market dynamics can lead to strategic advantages. Companies looking to enter or expand in this market should consider localization strategies to meet specific regulatory and consumer needs in the Asia-Pacific region. As the demand for hydraulic systems continues to rise, understanding competitive pressures and technological advancements will be crucial for sustaining growth.

Transforming Manufacturing: Impact of Automation on Hydraulic System Efficiency

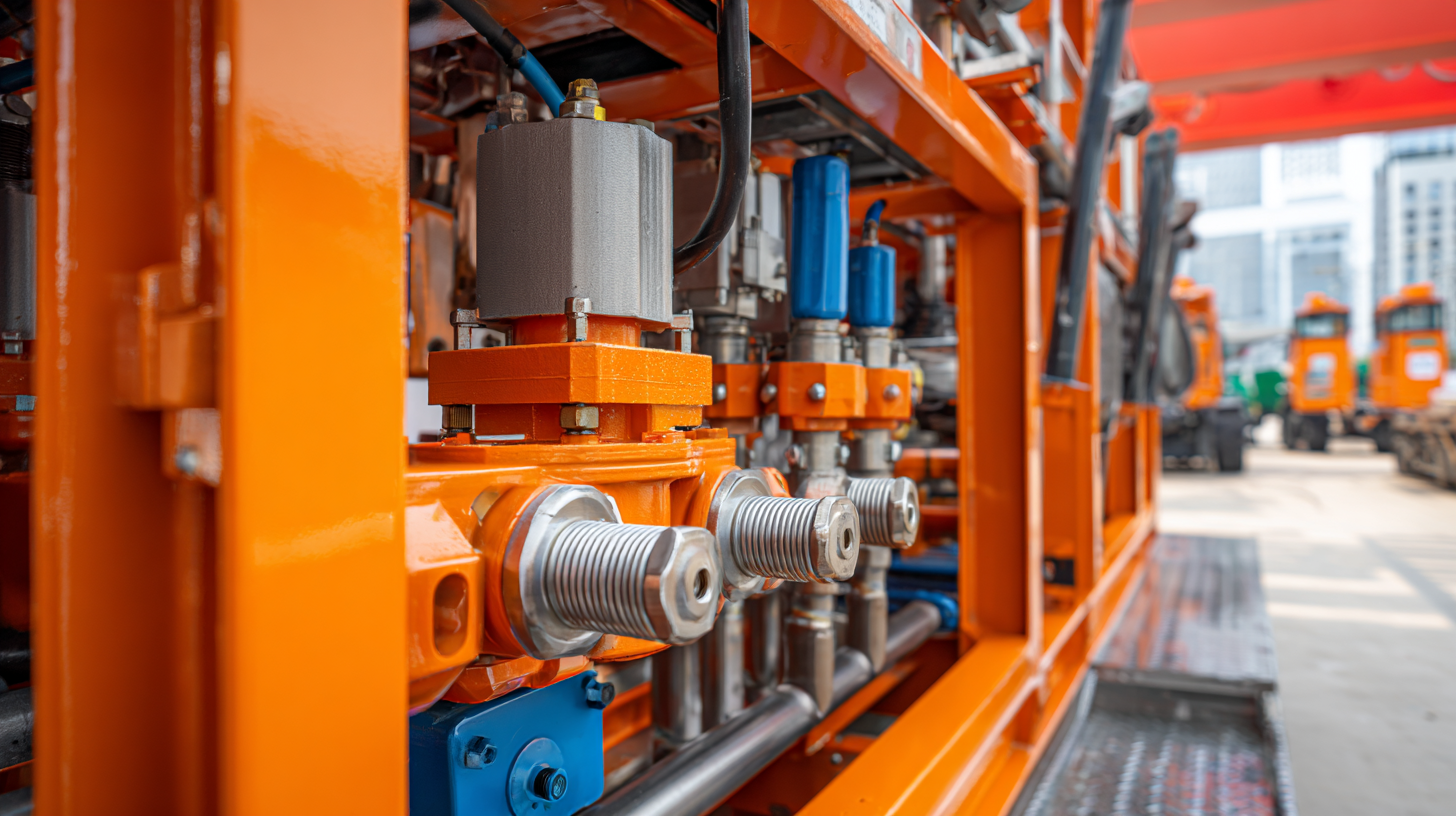

The integration of automation into hydraulic systems is poised to redefine manufacturing efficiency at the 138th China Import and Export Fair 2025. With advancements in technology, automated hydraulic systems are becoming increasingly prevalent, enhancing operational precision and reducing human error. These systems utilize sensors and smart controls to optimize performance, leading to significant gains in productivity and cost-effectiveness. As manufacturers adopt these innovations, they find that not only are their processes streamlined, but also their overall energy consumption is reduced, contributing to more sustainable practices.

Moreover, the impact of automation on hydraulic system efficiency extends beyond immediate production benefits. It fosters a shift towards predictive maintenance, where real-time data analytics allow for proactive identification of potential failures before they occur. This approach minimizes downtime and extends equipment lifespan, creating a more resilient manufacturing environment. As industry leaders showcase these transformative trends at the fair, it becomes evident that embracing automation is not just a choice but a necessity for competitive market positioning in the evolving landscape of hydraulic systems.

Revolutionizing Hydraulic Systems Trends and Insights at the 138th China Import and Export Fair 2025

| Dimension | Data |

|---|---|

| Year | 2025 |

| Exhibitors | 300+ |

| Attendees | 10,000+ |

| Featured Trends | Automation, IoT Integration, Energy Efficiency |

| Impact of Automation | 40% Increase in Efficiency |

| Sustainability Focus | Reduction of Carbon Footprint by 25% |

| Future Innovations | Smart Sensors, Predictive Maintenance |

Related Posts

-

Essential Pneumatic Hydraulic Maintenance Checklist for Optimal Performance

-

7 Compelling Reasons to Choose Fluid Power Hydraulics for Your Industrial Needs

-

Innovative Solutions for Fluid Power Hydraulics Efficiency

-

Understanding Common Issues with Hydraulic Pumps and Motors in Industrial Applications

-

10 Essential Tips for Mastering Pneumatic and Hydraulic Systems

-

Pneumatic Hydraulics Versus Traditional Hydraulics A Comprehensive Comparison of Efficiency and Performance

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us