Unlocking the Secrets of Fluid Power Mechanics for Everyday Applications

Fluid power is an essential mechanism that plays a pivotal role in various everyday applications, from industrial machinery to automotive systems. By harnessing the principles of hydraulics and pneumatics, fluid power enables the efficient transfer of energy through liquids and gases, facilitating movement and control in countless devices and systems. This article aims to unravel the intricate mechanics of fluid power, exploring its fundamental concepts, components, and the innovative ways it is utilized in our daily lives.

Whether powering construction equipment, enabling precision in manufacturing processes, or enhancing safety in transportation, understanding the secrets of fluid power mechanics empowers us to appreciate the technology that drives modern society. As we delve deeper into this fascinating field, we will uncover how fluid power not only enhances efficiency but also promotes sustainability and innovation across various sectors, highlighting its significance in our interconnected world.

Understanding Fluid Power: The Basics You Need to Know

Fluid power mechanics is a powerful technology that utilizes fluids to create movement and control in various applications. The fundamental principles behind fluid power systems include hydraulics and pneumatics. Hydraulics harness the power of liquids under pressure, while pneumatics utilizes compressed gases. By understanding these basics, individuals can appreciate the efficiency and versatility that fluid power brings to everyday machinery and equipment, from construction vehicles to household appliances.

Tip: When working with hydraulic systems, always ensure that the fluid is clean and at the appropriate level to avoid damage and maintain performance. In pneumatic systems, regularly check for leaks in the hoses and fittings to ensure optimal efficiency and safety.

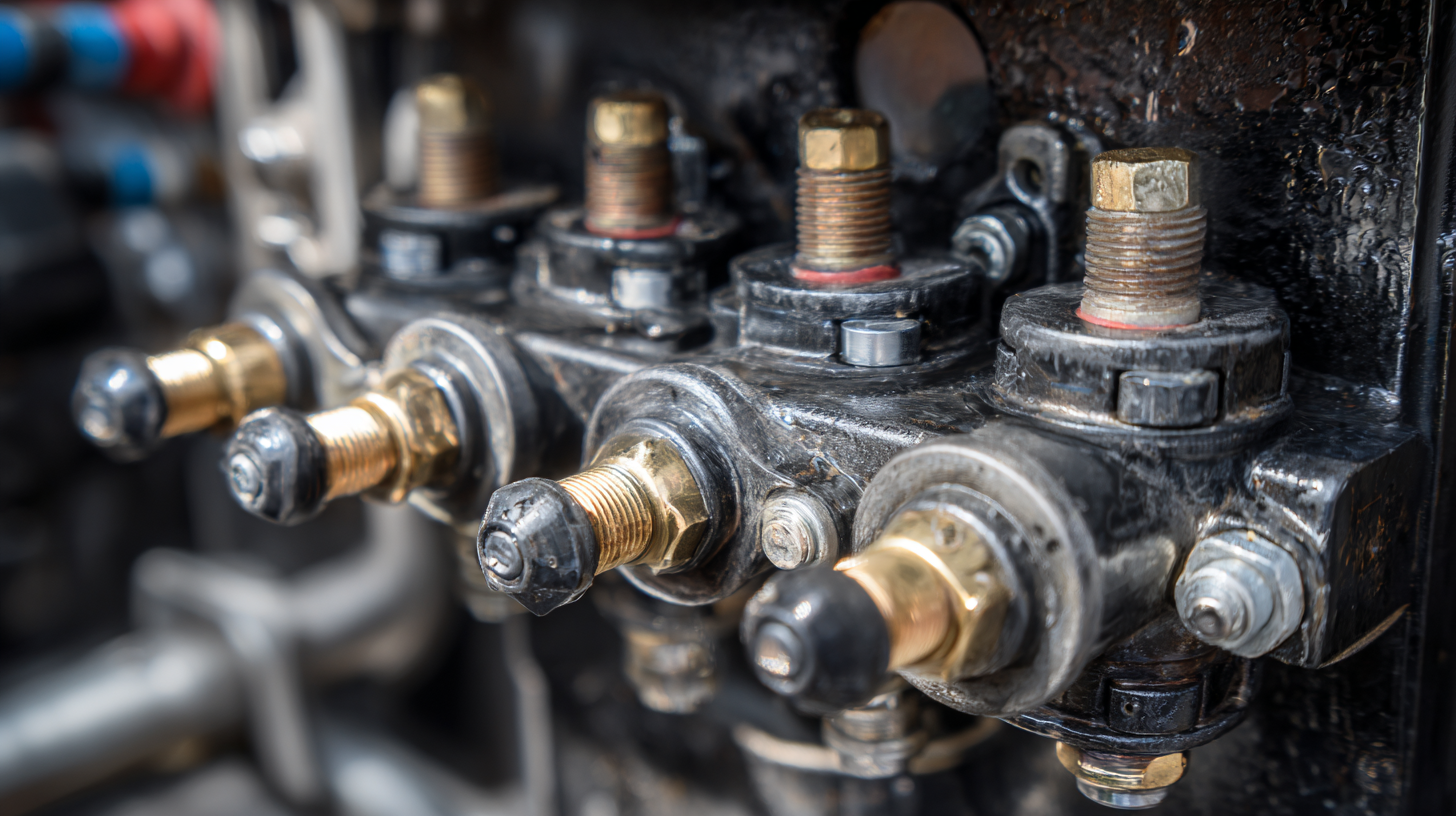

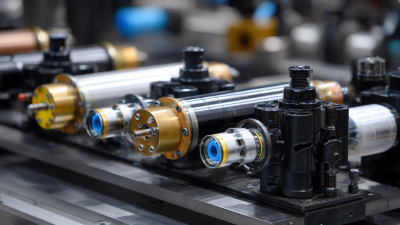

Another important aspect of fluid power mechanics is the components involved, such as pumps, actuators, and valves. Each plays a crucial role in the functionality of a fluid power system. Pumps move the fluid, actuators convert the fluid energy into mechanical work, and valves control the flow and direction of the fluid. Understanding these components allows for better troubleshooting and maintenance of systems that rely on fluid power.

Tip: Familiarize yourself with the specifications of the components in your fluid power system. This knowledge can help you make informed decisions when performing repairs or upgrades, ultimately enhancing your system's performance and longevity.

Common Applications of Fluid Power in Everyday Life

Fluid power mechanics play a vital role in numerous everyday applications, significantly impacting both industrial and domestic environments. One of the most common uses of fluid power is in hydraulic machinery, such as construction equipment like excavators and bulldozers. These machines utilize hydraulic systems to lift heavy loads effortlessly, demonstrating the efficiency and power transfer capabilities of fluid mechanics in action. Similarly, fluid power is employed in automotive systems, where hydraulic brakes and steering enhance vehicle control and safety.

In addition to industrial applications, fluid power is also prevalent in household devices. For example, dishwashers and washing machines often rely on hydraulic systems to circulate water efficiently for cleaning purposes. Additionally, fluid power is utilized in power tools, like hydraulic jacks, which provide mechanical advantage for lifting heavy objects with minimal physical effort. As such, the principles of fluid power mechanics not only enable advancements in technology but also enhance convenience and productivity in our daily lives.

Unlocking the Secrets of Fluid Power Mechanics for Everyday Applications - Common Applications of Fluid Power in Everyday Life

| Application | Description | Fluid Power Type | Everyday Use |

|---|---|---|---|

| Hydraulic Brakes | Utilize hydraulic fluid to transfer force from the brake pedal to the brake pads. | Hydraulic | Cars, Bicycles |

| Power Steering | Uses hydraulic pressure to assist steering maneuvers. | Hydraulic | Vehicles |

| Elevators | Use hydraulic systems to lift and lower the car. | Hydraulic | Buildings, Shopping Centers |

| Construction Equipment | Heavy machinery like bulldozers and backhoes use hydraulic systems to perform tasks. | Hydraulic | Construction Sites |

| Air Conditioning Systems | Use fluid dynamics to circulate refrigerant and generate cool air. | Pneumatic | Homes, Offices |

Key Components of Fluid Power Systems Explained

Fluid power systems are a critical component of numerous applications, from industrial machinery to automotive systems. At the heart of these systems lies a selection of key components, each playing a vital role in ensuring efficiency and reliability. Hydraulic pumps, for instance, are essential for converting mechanical energy into hydraulic energy, enabling the movement of fluids. Additionally, valves manage the flow of fluid, providing precise control over pressure and direction. Understanding these components is crucial for optimizing fluid power applications and addressing common challenges, such as engineering obsolescence.

Recent advancements, particularly in additive manufacturing, have opened new avenues for enhancing hydraulic systems. For example, the integration of additive manufacturing technologies enables the creation of complex components that can improve performance and reduce production costs. This innovative approach also allows for the reverse engineering of obsolete parts, ensuring that military vehicles and other critical systems remain operational. As hydraulic systems continue to evolve, leveraging these key components and emerging technologies will be essential for maximizing their potential in everyday applications.

Tips for Maintaining Fluid Power Equipment Effectively

When it comes to maintaining fluid power equipment, preparation is key, especially before and after seasonal storage. One important tip is to thoroughly clean the equipment, removing any dirt or debris that could cause damage during storage. Additionally, checking for any leaks or damages to hoses and fittings ensures that your system remains in optimal condition. Always remember to top off hydraulic fluids to their recommended levels; this prevents air contamination and helps maintain system integrity.

Another crucial aspect of maintaining fluid power systems is the proper selection of fluids. It’s essential to use high-quality hydraulic fluids that offer superior wear protection and thermal stability. For those operating machinery in extreme temperatures, using specialized fire-resistant fluids can add an extra layer of safety while enabling efficient operation. Lastly, regular inspections before and after the storage period will identify any potential issues early on, ensuring that your equipment runs smoothly when it's back in action.

Safety Precautions When Working with Fluid Power Mechanics

When working with fluid power mechanics, adhering to safety precautions is paramount. According to a report by the Fluid Power Educational Foundation, approximately 50% of all hydraulic accidents are caused by system failures or operator error. It is essential for individuals to understand the common risks associated with hydraulic systems, such as high-pressure leaks, which can lead to serious injuries or equipment damage. Proper personal protective equipment (PPE), including gloves, safety goggles, and face shields, should always be utilized when operating hydraulic machinery.

Additionally, regular maintenance and inspections are crucial components of workplace safety in fluid power mechanics. The International Fluid Power Society emphasizes that implementing a robust maintenance schedule can reduce the risk of catastrophic failures by up to 30%. Training operators in emergency shutdown procedures and the correct handling of hydraulic fluids can further mitigate risks. It is essential not only to be familiar with the equipment but also to cultivate a safety-first culture within teams to ensure that fluid power mechanics can be harnessed effectively and safely in everyday applications.

Fluid Power Mechanics Safety Precautions

This bar chart illustrates the importance of various safety precautions when working with fluid power mechanics. The data represents the percentage of safety incidents related to different precautions taken over a period of time. Proper adherence to safety measures is crucial to minimize risks in fluid power applications.

Related Posts

-

Unveiling the Future of Fluid Power Hydraulics in Sustainable Engineering

-

10 Essential Tips for Mastering Pneumatic and Hydraulic Systems

-

7 Compelling Reasons to Choose Fluid Power Hydraulics for Your Industrial Needs

-

Innovative Solutions for Fluid Power Hydraulics Efficiency

-

How to Optimize Your Operations with Innovative Hydraulic Solutions

-

Understanding the Importance of Hydraulic Components in Modern Machinery

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us