2025 Top 5 Hydraulic Pumps and Motors You Need for Optimal Performance

In the rapidly evolving world of industrial machinery, hydraulic pumps and motors play a critical role in enhancing operational efficiency and performance. According to a report by the Research Institute for Hydrostatic Technology, the global hydraulic pump market is projected to reach USD 23.5 billion by 2025, with a compound annual growth rate (CAGR) of 3.6% from 2020 to 2025. This significant growth underscores the increasing demand for high-performance hydraulic systems across various sectors, including construction, manufacturing, and agriculture.

To optimize their performance, industries are seeking out the best hydraulic pumps and motors that not only meet their operational needs but also adhere to sustainability standards. The International Fluid Power Society highlights that advancements in technology and innovative designs are leading to more efficient hydraulic solutions, resulting in reduced energy consumption and reduced environmental impact. In this context, understanding the top hydraulic pumps and motors available in 2025 becomes essential for businesses aiming to maintain their competitive edge and achieve optimal performance in their operations.

Top 5 Hydraulic Pump Models to Maximize Energy Efficiency in 2025

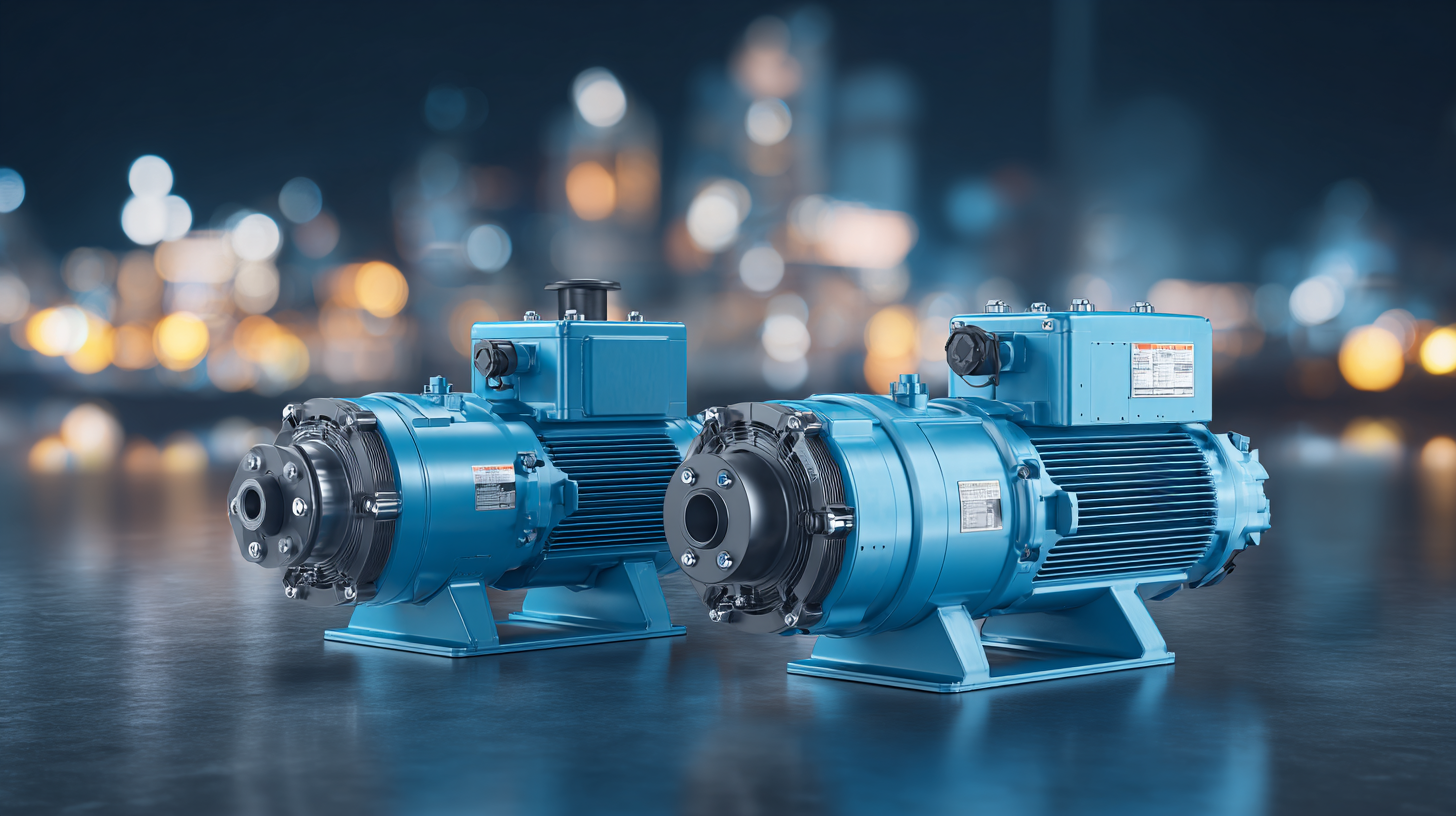

When selecting hydraulic pumps and motors for optimal energy efficiency in 2025, it's crucial to focus on models that integrate advanced technology and design. The top choices are likely to include variable displacement pumps which adjust flow based on demand, significantly reducing energy waste. Additionally, electric hydraulic loaders are becoming more popular due to their enhanced efficiency compared to traditional models.

Tips: Consider evaluating the energy consumption metrics of each model before making a purchase. Look for features such as integrated smart technology that optimizes performance based on real-time system demands. Regular maintenance and inspections can also prolong the lifespan and efficiency of your hydraulic systems.

Moreover, innovative materials and designs will play a pivotal role in maximizing efficiency. Lightweight materials can reduce the overall weight of the hydraulic system, which can contribute to lower fuel consumption in mobile applications. Always ensure that the selected pump or motor is compatible with your existing system to avoid any performance issues.

Best Hydraulic Motors for Superior Power Delivery and Performance

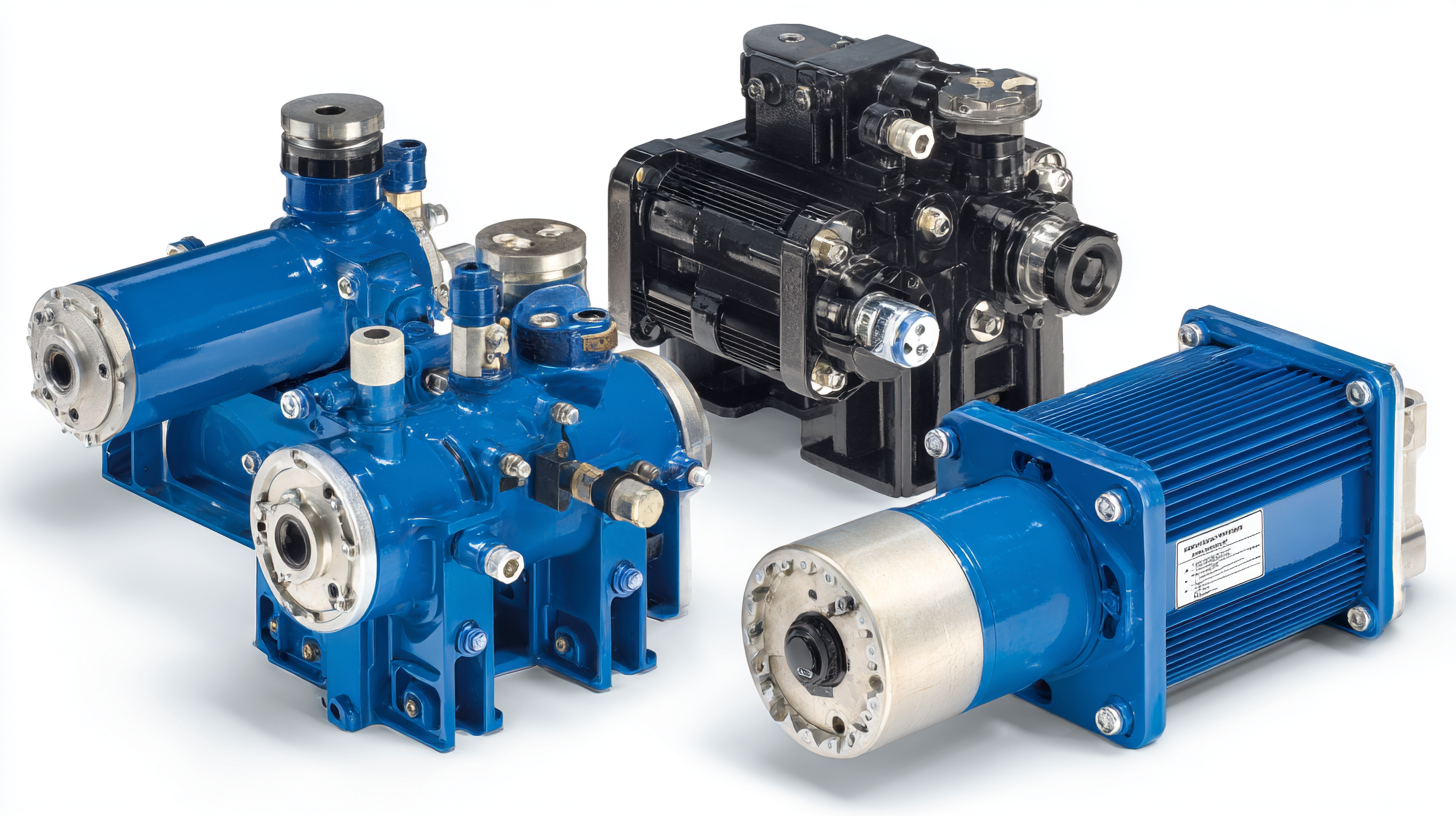

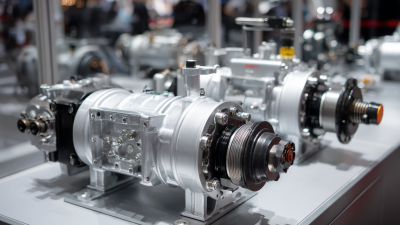

When it comes to hydraulic systems, selecting the right hydraulic motors is crucial for achieving superior power delivery and optimal performance. According to the latest industry analysis by MarketsandMarkets, the hydraulic motors market is projected to reach $11.3 billion by 2025, driven by the rising demand for efficiency in industrial applications. Among various options, gear and piston motors stand out due to their efficiency and precision in power transmission, making them ideal for applications in construction, manufacturing, and agriculture.

One of the leading hydraulic motors, the bent-axis piston motor, is known for its high torque and operational reliability, offering efficiency ratings well above 90%. Additionally, hydraulic gear motors provide a cost-effective solution with the capability to support high-speed applications while maintaining durability. Research indicates that integrating advanced hydraulic motors can improve system efficiency by over 30%, thereby significantly reducing energy consumption and operational costs. As industries strive for energy efficiency and performance, investing in the best hydraulic motors available can lead to substantial long-term benefits.

Key Features to Consider When Selecting Hydraulic Pumps and Motors

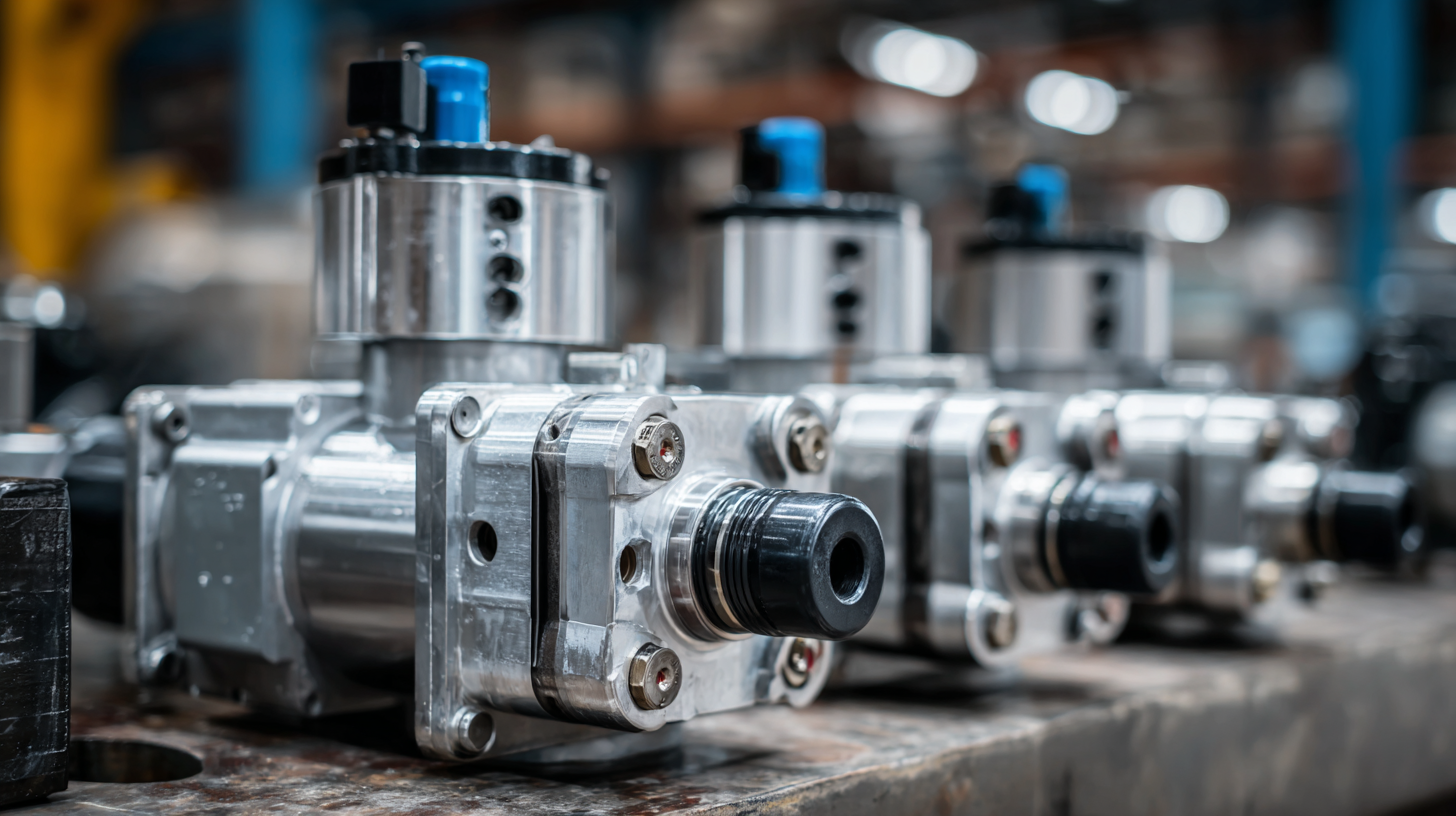

When selecting hydraulic pumps and motors for optimal performance, understanding key features is crucial. Efficiency ratings play a significant role; for instance, higher efficiency translates to lower operational costs and enhanced performance in various applications. Additionally, the material construction of hydraulic components affects durability and resistance to wear, particularly in demanding environments where high-pressure operations are common. Recent research indicates that hydraulic systems utilizing advanced gear technology show a 15% increase in efficiency compared to traditional designs, making them a preferred choice in industrial applications.

Noise reduction is another essential factor. Newer hydraulic motors are designed to minimize operational noise through innovations such as noise-dampening materials and improved engineering techniques. Data suggest that advancements in motor design can reduce sound levels by up to 20 decibels, which enhances the working environment, particularly in noise-sensitive areas. Moreover, vibration control features are critical, as excessive vibration can lead to equipment failure and increased maintenance costs. Choosing hydraulic pumps and motors equipped with effective vibration dampening systems results in a significant mitigation of these risks, ensuring long-term reliability and efficiency in hydraulic operations.

Comparative Analysis of the Best Hydraulic Systems for 2025

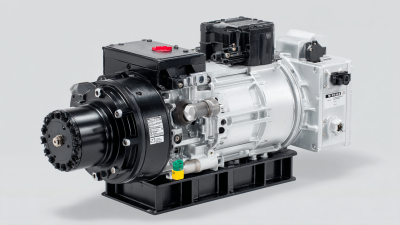

In the rapidly evolving landscape of hydraulic systems, the year 2025 is set to exhibit substantial advancements in hydraulic pump and motor technologies. This comparative analysis explores the top five hydraulic pumps and motors that promise to deliver optimal performance across various applications. Each model is evaluated based on efficiency, durability, and ease of maintenance, ensuring users select the best fit for their operational needs.

Among the frontrunners, the latest models incorporate innovative designs that enhance flow rates while minimizing energy consumption. For instance, advanced variable displacement pumps are gaining attention for their adaptability to varying load conditions, providing both power and precision. Additionally, smart motor technology is revolutionizing the way hydraulic systems operate, allowing for greater control and integration with automated systems. By comparing these attributes across the leading products, users can make informed choices that will enhance their overall hydraulic performance and productivity in 2025.

2025 Top 5 Hydraulic Pumps and Motors You Need for Optimal Performance

| Type | Max Pressure (psi) | Flow Rate (GPM) | Efficiency (%) | Weight (lbs) | Noise Level (dB) |

|---|---|---|---|---|---|

| Gear Pump | 4000 | 12 | 90 | 30 | 75 |

| Piston Pump | 5000 | 10 | 95 | 45 | 78 |

| Vane Pump | 3500 | 15 | 88 | 25 | 72 |

| Axial Piston Motor | 6000 | 8 | 93 | 50 | 80 |

| Radial Piston Motor | 4500 | 6 | 94 | 55 | 76 |

Essential Maintenance Tips for Optimal Performance of Hydraulic Equipment

Maintaining hydraulic equipment is crucial for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents costly breakdowns. One of the first steps in maintaining hydraulic pumps and motors is to check fluid levels and quality. Contaminated or low fluid can lead to significant wear and tear, so make it a habit to regularly inspect and replace hydraulic fluid as necessary.

Another essential tip is to monitor the temperature of your hydraulic system. Overheating can cause severe damage to components and compromise system performance. Ensure that cooling systems are functioning properly and consider implementing temperature monitoring systems to provide real-time data. Additionally, pay attention to the condition of hoses and fittings, as leaks can severely impact system performance. Regularly inspecting these components and replacing them at the first signs of wear can prevent more extensive damage.

Finally, don’t overlook the importance of a routine inspection schedule. Keeping a record of maintenance activities, including fluid changes and component inspections, can help you identify patterns that might indicate underlying issues. By taking a proactive approach and adhering to these maintenance tips, you can ensure your hydraulic equipment operates at peak performance.

Related Posts

-

How to Optimize Air Hydraulic Pump Performance for Maximum Efficiency

-

5 Essential Tips for Choosing the Right Hydraulic Pump Motor for Your Industrial Needs

-

What is Hydraulic Pump Repair and Why It Matters for Industry Efficiency

-

7 Best Hydraulic Motors for Efficient Energy Solutions in 2024

-

How to Optimize the Performance of Your Hydraulic Pump Motor

-

Unveiling Trends in Electric Hydraulic Pump Demand at China's 138th Canton Fair 2025: Market Insights and Growth Forecasts

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us