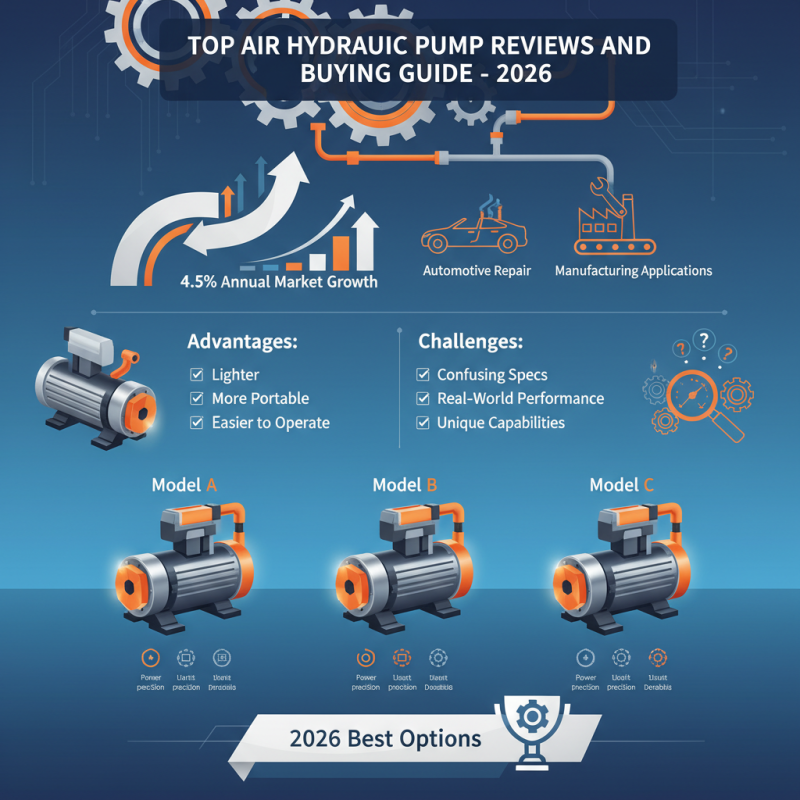

2026 Top Air Hydraulic Pump Reviews and Buying Guide?

In the world of industrial tools, the air hydraulic pump stands out for its efficiency and versatility. According to a recent industry report, the market for hydraulic pumps is projected to grow by 4.5% annually. This growth reflects the increasing demand for automated machinery and construction equipment. Air hydraulic pumps are critical in various applications, from automotive repair to manufacturing.

These pumps offer significant advantages over traditional hydraulic pumps. They are lighter, more portable, and easier to operate. With the right air hydraulic pump, technicians can achieve quick and precise hydraulic power without the bulk of older systems. However, choosing the right model can be challenging. With numerous options on the market, it’s often tough to identify quality features.

Many users report confusion about pump specifications and applications. Some models may promise high performance but fail in real-world scenarios. It's essential to recognize that each air hydraulic pump has unique capabilities. Understanding these differences is key to making an informed decision. This guide aims to simplify that process and highlight the best options available for 2026.

2026 Air Hydraulic Pumps: An Overview of Types and Features

Air hydraulic pumps come in various types, each designed for specific tasks. The most common types include single-acting and double-acting pumps. Single-acting pumps pressurize fluid in one direction, while double-acting pumps do so in both directions. This feature is crucial for efficiency and speed in demanding applications.

When selecting an air hydraulic pump, consider key features like pressure rating, pump size, and flow rate. A higher pressure rating often means better performance for heavy-duty tasks. Additionally, the size of the pump can affect portability. Smaller models may be easier to transport, but larger models typically offer higher power.

Tips: Always check compatibility with your intended tools. Some pumps work best with particular hydraulic tools. If you're unsure, consult a manual or expert. Make sure to maintain your pump regularly. A well-maintained pump can last longer and perform better.

Not every pump will fit every need. It's important to evaluate your specific requirements carefully. Sometimes, the most powerful option isn't the best choice. A pump that meets your needs without being overly complex can be more beneficial in the long run. Choose wisely!

Key Specifications to Consider When Choosing an Air Hydraulic Pump

When choosing an air hydraulic pump, it’s essential to focus on key specifications. Pay close attention to the pump's capacity. This determines how much load it can handle. A pump that is too small will struggle, while one that is too large may lead to inefficiencies. Consider the pressure rating as well. Higher pressure ratings enable more forceful operations.

The design of the pump also matters significantly. Look for features like a robust body and easy-to-use controls. Portable models may be convenient but often compromise power. Stability is crucial; unstable pumps can lead to accidents. Noise levels can be important, especially if used in a residential area.

Don’t overlook the compatibility with your existing tools. Checking the connector sizes can prevent headaches later. Some users find they need adapters, which can be frustrating. Reviews often highlight durability; ensure you choose a model that lasts. Take your time to evaluate all these factors. A rushed decision can lead to regret down the line.

Top Brands and Models of Air Hydraulic Pumps for 2026

When looking for air hydraulic pumps in 2026, it's essential to consider various factors. Many pumps offer different pressure capacities. The design and materials used can impact durability and efficiency. Choose a pump that suits your specific needs. Don't overlook the importance of ensuring compatibility with your equipment.

Several top brands provide high-quality models. Some pumps are lightweight and compact. Others may be heavier but offer increased power. It's a balancing act. You might find that a more expensive model lasts longer, saving money in the long run. Look for user reviews before deciding.

You may also encounter challenges during your search. Some models might not perform as expected. Research can help you avoid pitfalls. Compare features and prices diligently. Often, the most popular models have the largest user base. Yet, they may not always meet individual needs. Keep an open mind and assess all options.

User Reviews: What Customers Are Saying About Their Air Hydraulic Pumps

User reviews play a crucial role in the decision-making process for air hydraulic pumps. Many users appreciate the efficiency and power these tools provide. A survey indicates that nearly 72% of customers reported satisfaction after their purchase. Users often highlight the significant reduction in labor time. For instance, some reported cutting project times by as much as 30%. This effectiveness results in improved productivity and cost savings in the long run.

Tips: Always read user reviews before making a decision. Real-world experiences can reveal common issues or advantages. For example, some users noted that certain models overheat quickly under heavy use. Others mentioned noise levels, which can be a concern in residential areas.

Visualizing the pump's capacity is essential. Many customers suggest looking for models rated for at least 10 tons of pressure. This rating ensures that the pump can handle tougher tasks with ease. However, some buyers mentioned that heavier pumps are less portable. It’s a balance between power and convenience. Focusing on these elements can lead to a more informed purchase.

2026 Top Air Hydraulic Pump Reviews and Buying Guide

| Model | Max Pressure (psi) | Pump Type | Oil Capacity (quart) | Weight (lbs) | Customer Rating |

|---|---|---|---|---|---|

| Pump A | 10,000 | Single-Acting | 2.5 | 25 | 4.5/5 |

| Pump B | 8,000 | Double-Acting | 3.0 | 30 | 4.0/5 |

| Pump C | 12,000 | Single-Acting | 2.0 | 28 | 4.8/5 |

| Pump D | 9,500 | Double-Acting | 3.5 | 22 | 4.3/5 |

| Pump E | 11,000 | Single-Acting | 2.8 | 32 | 4.7/5 |

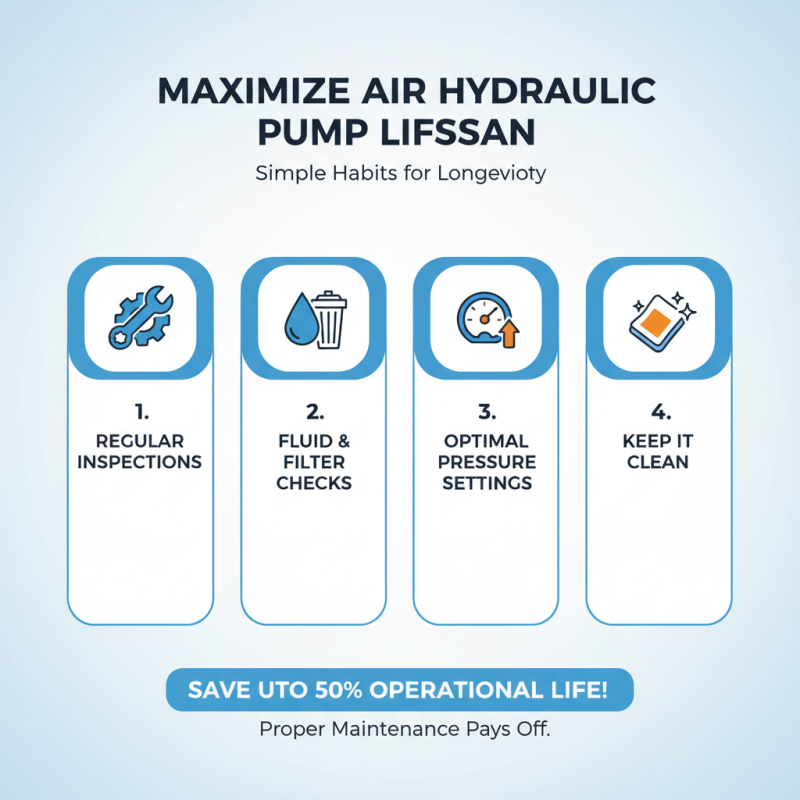

Maintenance Tips for Ensuring Longevity of Your Air Hydraulic Pump

Air hydraulic pumps are widely used in various industries for their power and efficiency. However, regular maintenance is crucial for ensuring their longevity. According to industry reports, improper maintenance can reduce a pump's operational life by up to 50%. Simple habits can significantly improve your pump's lifespan.

First, it's essential to check fluid levels regularly. Low fluid can cause overheating and damage internal components. Clean filters and oil can improve performance. Also, inspect hoses and connections; leaks can lead to inefficiencies. If you notice any wear, replace faulty parts immediately.

Tips: Always store your pump in a dry environment. Moisture can promote rust and corrosion. A dry, clean workspace extends the equipment’s life.

Don’t forget to bleed the air after any service. Trapped air can hinder performance. Moreover, keep a maintenance log. Document your actions to track performance issues over time. Small problems can escalate if ignored. Each of these habits contributes to smoother operation and reduced repair costs. Your diligence pays off in productivity and reliability.

Related Posts

-

How to Optimize Air Hydraulic Pump Performance for Maximum Efficiency

-

2025 Top 5 Hydraulic Pumps and Motors You Need for Optimal Performance

-

What is an Air Hydraulic Pump and How Does it Work for Your Needs

-

The Ultimate Guide to Electric Hydraulic Pumps in 2025 Trends and Innovations

-

What is Hydraulic Pump Repair and Why It Matters for Industry Efficiency

-

How to Optimize the Performance of Your Hydraulic Pump Motor

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us