Top 10 Air Hydraulic Pumps to Boost Your Efficiency?

In the fast-paced world of mechanical work, efficiency is key. An air hydraulic pump can enhance productivity in various applications, from automotive repairs to heavy machinery. These pumps are designed to convert air power into hydraulic force, making tasks smoother and quicker.

Choosing the right air hydraulic pump is crucial. Many options are available, each with unique features and capacities. Users often face a challenge in identifying the best ones. Knowing the top-rated models can help avoid costly mistakes.

Efficiency and performance are often compromised by poor choices. Regularly assessing the right equipment is essential. An effective pump can significantly reduce the time and effort needed for tasks. Enhancing your toolkit with the right air hydraulic pump could redefine your work efficiency.

Overview of Air Hydraulic Pumps and Their Applications

Air hydraulic pumps are versatile tools widely used in various industries. They convert air pressure into hydraulic force, making lifting and moving heavy objects much easier. Many workshops and construction sites rely on these pumps for efficiency. They can reduce labor costs and speed up projects, which is crucial in today’s fast-paced work environment.

These pumps find applications in automotive repair, manufacturing, and construction. They can operate a range of hydraulic tools, like jacks and presses, enabling tasks like lifting vehicles or shaping metal. The design of air hydraulic pumps can vary significantly, affecting their performance and suitability for specific tasks. For instance, some models are portable, while others are stationary and more powerful.

Despite the effectiveness of air hydraulic pumps, they are not without drawbacks. Users may face issues with air supply, leading to inconsistent performance. Proper maintenance is essential, yet often overlooked. Operators should regularly check for leaks and wear to maintain pump efficiency. The learning curve can also be steep for those unfamiliar with hydraulic systems. The benefits are clear, but awareness of potential pitfalls is vital.

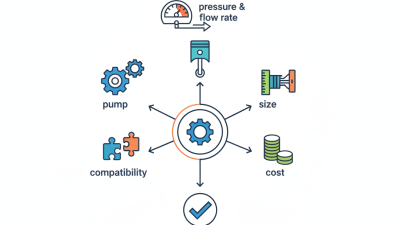

Key Features to Consider When Choosing Air Hydraulic Pumps

When choosing air hydraulic pumps, several key features stand out. First, consider the pump’s capacity. A higher capacity can handle more weight, making tasks easier. Reports show that pumps with a capacity of 10 tons can increase efficiency by nearly 30%. This can significantly reduce time spent on heavy lifting projects.

Next, look at the pump’s pressure output. Most effective air hydraulic pumps deliver between 100 to 150 PSI. This level is optimal for a wide range of applications. Lower pressure may lead to slower performance and inefficiency. If the output is too high, it may cause damage to components. Balance is crucial.

Durability is another factor. Pumps made with high-quality materials last longer, reducing downtime. However, cheaper materials may lead to frequent repairs. According to industry insights, about 20% of pump failures are due to poor material quality. Maintenance requirements are essential as well. Pumps that are easy to service can save time and costs in the long run. Evaluating these aspects can lead to better choices and improved productivity.

Top 10 Air Hydraulic Pumps Reviewed: Performance and Specifications

When selecting air hydraulic pumps, efficiency and performance are crucial. A recent industry report highlighted that proper pump selection can improve productivity by up to 25%. These pumps can handle high-pressure tasks and are vital in various applications, from automotive repair to manufacturing. Each model varies in specifications, including flow rate and pressure capacity, making it essential to choose wisely.

Some models can lift loads exceeding 10 tons, while others are designed for smaller jobs. The variability in construction materials and design can also impact durability. Reports indicate that pumps with reinforced bodies tend to last longer under heavy use. However, not all pumps meet these durability standards. Users often overlook maintenance, which can lead to performance issues over time. Regular checks can mitigate risks and prolong pump life.

Operating costs are also a factor. Air hydraulic pumps consume varying amounts of energy, affecting the overall efficiency. A study found that energy-efficient models cut costs by nearly 15%. Yet, many users choose cost over efficiency, leading to increased long-term expenses. The balance between initial investment and operational savings is delicate but necessary for optimizing performance.

Comparative Analysis of the Best Air Hydraulic Pumps on the Market

When considering air hydraulic pumps, efficiency is key. Various designs on the market offer different benefits. Some models excel in compactness, making them ideal for tight spaces. Others provide greater power output, suitable for heavy-duty applications. Users often face a dilemma: should they prioritize portability or power?

The comparative analysis shows that not all pumps suit every task. Some can fail under high pressure, requiring frequent checks. Additionally, noise levels can vary greatly, affecting workplace comfort. A few pumps are difficult to operate, leading to frustration. Choosing wisely requires assessing specific needs.

Customer reviews often highlight reliability as a crucial factor. A highly-rated pump can enhance workflow significantly. However, user experiences differ widely, indicating that one size doesn’t fit all. Taking time to weigh the options will ultimately boost performance and satisfaction.

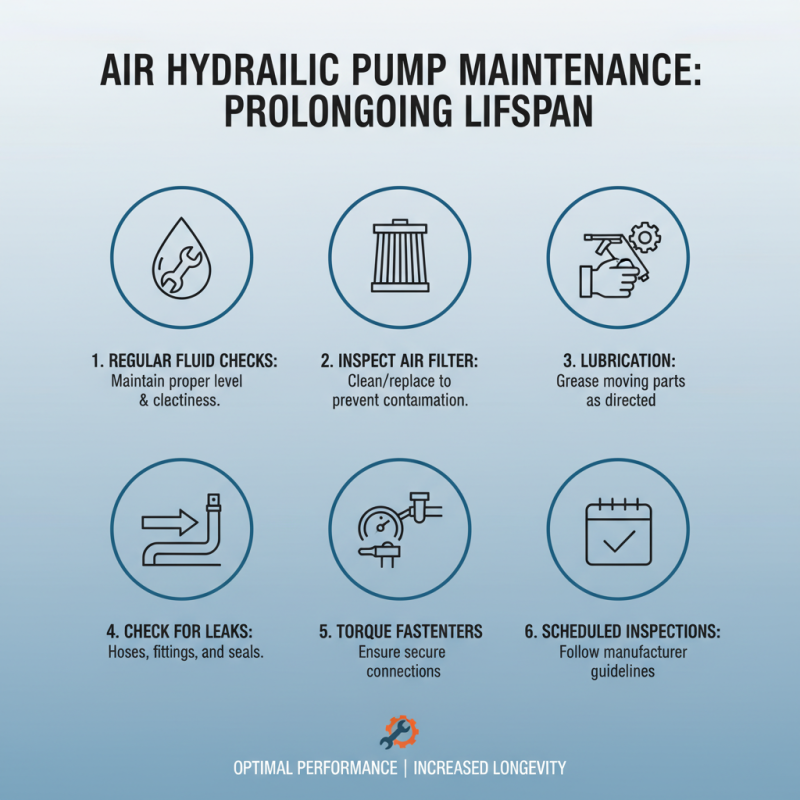

Maintenance Tips for Prolonging the Life of Air Hydraulic Pumps

Air hydraulic pumps are essential tools for many industries. However, they require regular maintenance to ensure optimal performance. Here are some valuable tips to help you prolong their lifespan.

Proper lubrication is crucial. Check the oil level frequently. Use the right type of oil to avoid damage. Dirty oil can lead to wear and tear. Replace oil when necessary. Clean the pump exterior as debris can cause overheating. Check for leaks regularly, as they can reduce efficiency.

Inspect the hoses and connections often. Look for cracks or signs of wear. If you see any issues, replace parts promptly. Ensure all fittings are tight. Loose connections may lead to air loss. Regularly test the pump under load to ensure it functions well. It's normal to encounter minor issues; address them quickly to avoid bigger problems later.

Related Posts

-

2025 Top 5 Hydraulic Pumps and Motors You Need for Optimal Performance

-

The Ultimate Guide to the Best 5 Air Hydraulic Pumps for Efficient Performance in 2023

-

What is an Air Hydraulic Pump and How Does it Work for Your Needs

-

2026 Top Air Hydraulic Pump Reviews and Buying Guide?

-

Electric Hydraulic Pump Tips for Efficiency and Maintenance?

-

How to Choose the Right Hydraulic Pump for Your Project?

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us