Top 5 Hydraulic Fittings to Enhance Your Equipment Performance?

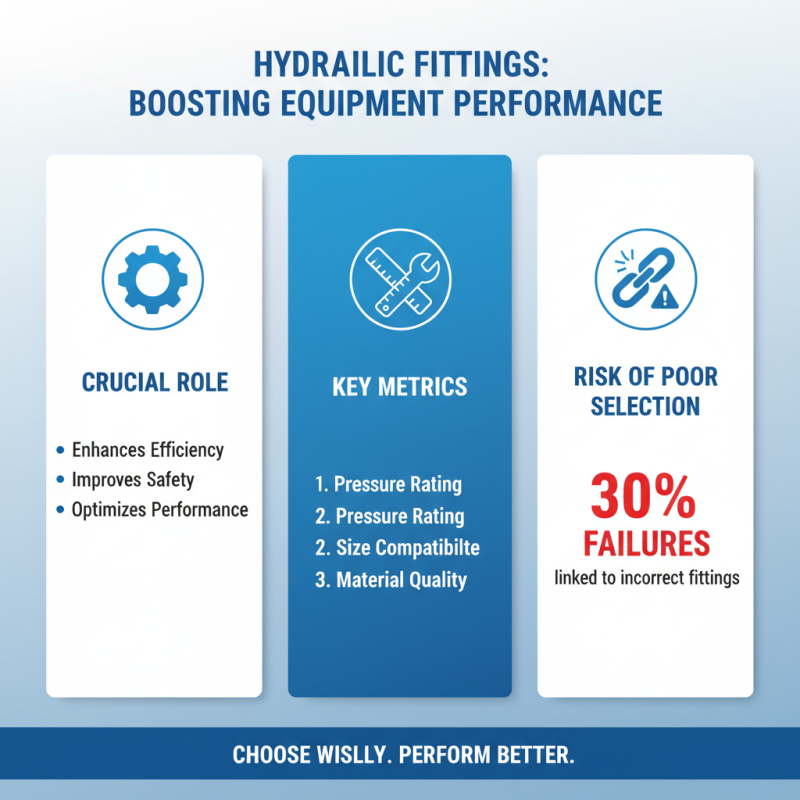

Hydraulic fittings play a crucial role in the performance of hydraulic systems. According to recent industry reports, improper or substandard fittings can lead to inefficiencies and safety hazards. The global hydraulic fittings market is projected to reach over $5 billion by 2025, reflecting the increasing demand for high-quality components.

The correct hydraulic fittings can significantly enhance equipment productivity. Quality fittings ensure optimal fluid flow, which is vital for operational efficiency. Reports indicate that nearly 30% of hydraulic failures are linked to fitted components. This fact highlights the importance of choosing the right components. However, not all fittings are created equal.

Many companies still overlook the significance of proper fitting selection. This oversight can result in costly downtime and repairs. It’s imperative to assess the specifications of hydraulic fittings carefully. Investing in reliable fittings is not just a choice; it’s a necessity for improved equipment performance and safety.

Top 5 Essential Hydraulic Fittings for Improved Equipment Efficiency

Choosing the right hydraulic fittings is crucial for enhancing equipment performance. These small components play a significant role in the efficiency of hydraulic systems. Reports have shown that improper fittings can reduce system efficiency by up to 30%. This inefficiency may lead to increased operational costs and frequent maintenance.

One essential type of hydraulic fitting is the quick-connect coupling. It allows for easy and rapid connection and disconnection. This convenience can save valuable time during equipment setup and maintenance. A survey indicated that companies utilizing quick-connect fittings reported a 25% increase in operational efficiency. However, some users overlook the importance of maintaining these fittings regularly. Neglect can lead to leaks or connection failures.

Another vital fitting is the flange fitting, known for its durability. Flange fittings are often used in high-pressure applications. They can handle extreme conditions better than other types. Yet, many users still choose less robust alternatives, risking system integrity.

Tip: Always assess your hydraulic system's specific needs before selecting fittings. Consider the operating pressure, fluid type, and environmental conditions. Proper selection can significantly impact long-term performance and safety. Regular inspection and replacement of worn fittings can prevent costly downtimes.

Understanding the Role of Hydraulic Fittings in Fluid Power Systems

Understanding the role of hydraulic fittings in fluid power systems is crucial for enhancing equipment performance. These fittings connect various components in hydraulic systems, ensuring efficient fluid transfer. A proper seal prevents leaks, which can waste power and reduce efficiency. Each fitting type serves a specific purpose, impacting flow rates and pressure levels.

When selecting hydraulic fittings, consider the material used. Steel, brass, and plastic are common options, each with unique properties. Steel is durable but can corrode. Brass offers good resistance, while plastic is lightweight but not as strong. Make sure the fitting matches the requirements of your application.

Tip: Always check compatibility between fittings and hoses. Mismatched parts can lead to failures. Regular maintenance is key. Inspect fittings for wear and tear, as damaged parts can compromise system performance. It's easy to overlook these details, yet they are vital for reliability. Keep spare fittings on hand for quick replacements, ensuring your system remains operational.

Key Performance Metrics for Selecting Hydraulic Fittings

Hydraulic fittings play a crucial role in the performance of equipment. Selecting the right fittings can enhance efficiency and safety. Key performance metrics should include pressure rating, size compatibility, and material quality. According to industry reports, up to 30% of hydraulic system failures are linked to poor fitting selection.

Pressure ratings dictate how much stress a fitting can withstand. Many fittings are rated between 3,000 to 10,000 psi. Choosing a fitting that exceeds your system's needs is wise but costly. Size matters too; mismatched sizes can lead to leaks or failures. An estimated 20% of leaks occur due to improper sizing.

Material quality is another critical factor. Common materials include steel, stainless steel, and aluminum. Each has its own strengths and weaknesses. For example, while aluminum is lightweight, it may not handle high pressures as effectively as steel. This often raises concerns about durability. Reevaluating your material choice based on your operating environment can yield better long-term results.

Material Selection for Hydraulic Fittings: Durability vs. Weight

When selecting hydraulic fittings, the choice of material plays a crucial role. Durability is essential in harsh environments. However, weight is also a significant factor. Heavier fittings can add stress to the system. This could lead to premature wear and tear. Consider the specific application when choosing the material. For example, lightweight aluminum may be suitable for mobile equipment. But stainless steel might be better for high-pressure systems.

Balancing durability and weight is a challenge. Some materials are strong but heavy. Others are lightweight but less robust. This trade-off requires careful thought. Avoid assuming that heavier means better performance. Sometimes, the right lightweight option can outperform heavier alternatives. Examine the operating conditions your equipment will face. Factor in pressure, temperature, and environmental exposure.

In the quest for optimized performance, small details matter. Flaws in material choice can lead to failure. Regular assessments of fitting integrity are vital. Reflect on past experiences with fitting performance. Were the materials up to par? These reflections can guide future selections. A more informed choice can enhance equipment longevity and efficiency.

Top 5 Hydraulic Fittings to Enhance Your Equipment Performance

Case Studies: The Impact of Fittings on Equipment Performance Metrics

Hydraulic fittings play a crucial role in the performance of equipment. Recent case studies reveal significant metrics influenced by these components. For example, a report showed that using high-quality fittings can enhance hydraulic system efficiency by up to 20%. Another study indicated reduced leakage rates, leading to lower maintenance costs.

In one case, a manufacturing plant upgraded its fittings and observed a 15% increase in output. The new fittings improved fluid flow and reduced response times in machinery. However, not all upgrades yield immediate results. It's essential to evaluate the compatibility and specifications of fittings before implementation.

Tips: Always conduct performance assessments post-installation. Collect data on flow rates and pressure changes to measure impacts accurately. Regularly inspect fittings for wear and tear, as these can significantly affect performance metrics. A small oversight here can lead to larger issues down the line.

Top 5 Hydraulic Fittings to Enhance Your Equipment Performance

| Fitting Type | Material | Pressure Rating (PSI) | Temperature Range (°F) | Application | Performance Improvement (%) |

|---|---|---|---|---|---|

| JIC Fitting | Steel | 3000 | -40 to 250 | High-pressure hydraulic systems | 15 |

| NPT Fitting | Brass | 2000 | -30 to 300 | General plumbing applications | 10 |

| Flange Fitting | Stainless Steel | 5000 | -20 to 400 | Heavy machinery | 20 |

| Quick Disconnect Fitting | Aluminum | 4000 | -40 to 250 | Cleaning and maintenance | 12 |

| Push-to-Connect Fitting | Polymer | 1500 | -4 to 230 | Light-duty applications | 8 |

Related Posts

-

5 Essential Tips for Choosing the Right Hydraulic Pump Motor for Your Industrial Needs

-

7 Best Hydraulic Motors for Efficient Energy Solutions in 2024

-

Understanding the Essential Role of Hydraulic Power Packs in Modern Machinery

-

2025 Top 5 Hydraulic Pumps and Motors You Need for Optimal Performance

-

2026 Best Hydraulic Components for Optimal Performance?

-

Unlocking Efficiency with Hydraulic Power Packs Understanding Their Impact on Industrial Applications

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us