Understanding the Essential Role of Hydraulic Power Packs in Modern Machinery

In the realm of modern machinery, the hydraulic power pack plays an indispensable role that often goes unnoticed. This compact and efficient system harnesses fluid power to drive various hydraulic components, ensuring that machines operate smoothly and effectively. As industries increasingly lean towards automation and higher productivity, the importance of hydraulic power packs cannot be overstated. These systems not only provide the necessary force and motion but also enhance the overall performance and reliability of machinery. By understanding the intricacies of hydraulic power packs, businesses can make informed decisions about machinery selection and maintenance, ultimately leading to greater operational efficiency and reduced downtime. This article explores the essential functions, advantages, and applications of hydraulic power packs, underscoring their critical contribution to the advancement of modern industrial practices.

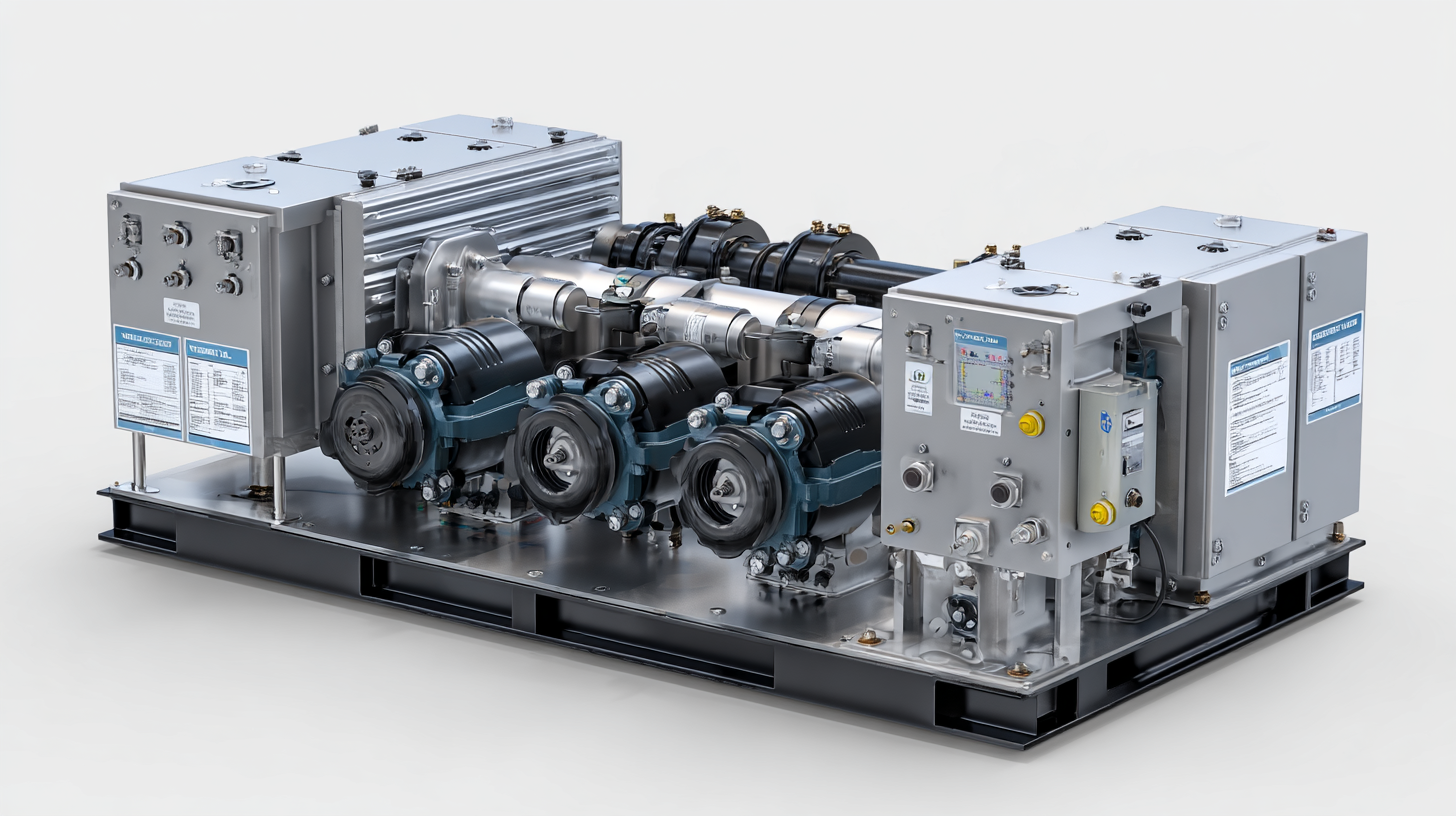

Identifying the Key Components of Hydraulic Power Packs in Machinery

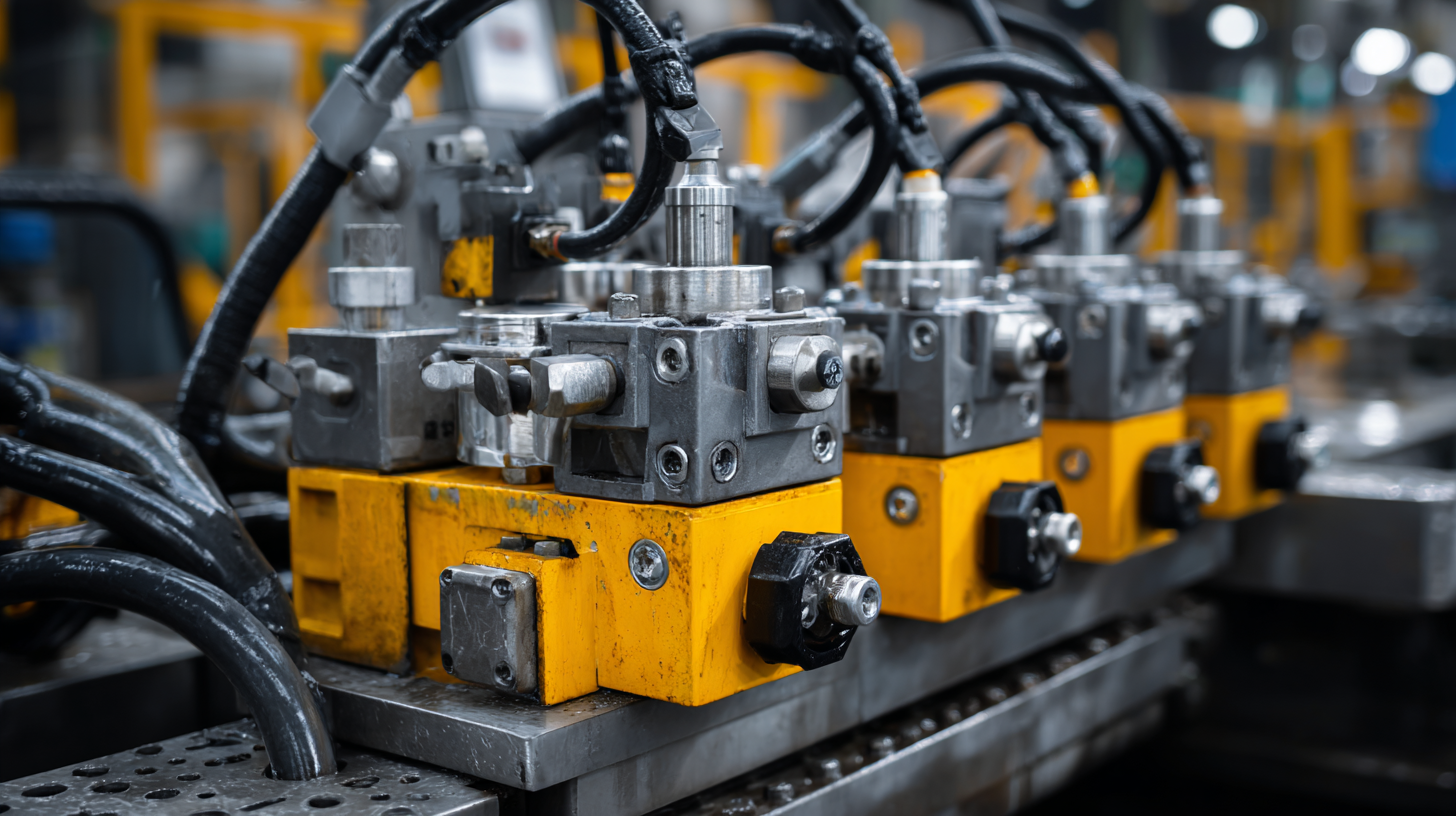

Hydraulic power packs play a crucial role in modern machinery, providing the necessary force to operate various components efficiently. Understanding the key components of these power packs is essential for anyone involved in industrial applications. Primarily, a hydraulic power pack consists of a hydraulic reservoir, pump, motor, and a series of valves that manage the fluid flow. The reservoir stores hydraulic fluid, while the pump generates the flow needed to power hydraulic actuators. The motor drives the pump, and the valves control pressure and flow to ensure optimal performance.

**Tips:** When maintaining hydraulic power packs, always check the fluid levels regularly. Low fluid can lead to pump failure or inadequate performance. Additionally, ensure that the filters are clean to prevent contaminants from damaging the hydraulic system. Another essential tip is to keep an eye on the pressure readings; fluctuations may indicate leaks or mechanical issues that need immediate attention.

Moreover, each of these components must be appropriately matched to achieve maximum efficiency. For example, selecting a motor with the right horsepower ensures that the pump operates efficiently within its designed range. Proper alignment and installation can also reduce wear and extend the lifespan of the equipment. Investing time in understanding these components will lead to enhanced performance and reduced downtime in machinery operations.

Understanding the Essential Role of Hydraulic Power Packs

This bar chart illustrates the key components of hydraulic power packs in modern machinery, showcasing the distribution of various components by percentage. The data reflects the common proportions of each component found in standard hydraulic systems.

Exploring the Benefits of Hydraulic Power Packs for Efficiency and Performance

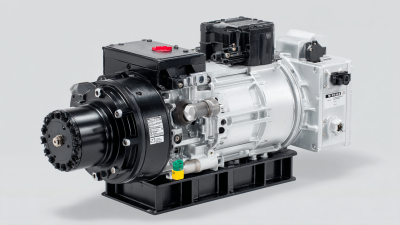

Hydraulic power packs play a pivotal role in enhancing both efficiency and performance in modern machinery. With the global hydraulic equipment market predicted to reach $65 billion by 2025, these systems are increasingly recognized for their ability to deliver high power outputs in compact designs. Hydraulic power packs convert mechanical energy into hydraulic energy, allowing for precise control over various machinery operations, which is essential in industries such as construction, manufacturing, and automotive. According to a report by MarketsandMarkets, the adoption of hydraulic systems can improve operational efficiency by 20-30%, showcasing their value in boosting productivity.

Moreover, hydraulic power packs contribute to performance optimization by offering advantages like increased torque and faster cycle times. A study published in the Journal of Mechanical Science estimated that machines utilizing hydraulic systems could operate up to 50% faster than their pneumatic counterparts, thanks to the superior power density of hydraulic fluids. Additionally, these packs require less maintenance due to fewer moving parts compared to traditional motor-driven systems, leading to lower downtime and operational costs. As machinery continues to advance, the integration of hydraulic power packs will be crucial in driving efficiency and performance standards to new heights.

Step-by-Step Guide to Selecting the Right Hydraulic Power Pack for Your Needs

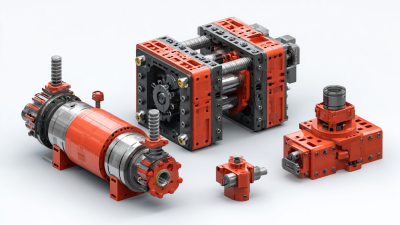

When selecting the right hydraulic power pack for your needs, it is crucial to assess several key factors that will influence performance and efficiency. First, consider the specific application for which the power pack will be used. Different tasks may require different flow rates, pressure levels, and sizes. For instance, if you are operating heavy machinery, a power pack with higher pressure capabilities and robust construction will be necessary to handle the demands of the equipment.

Next, evaluate the power source and convenience of the hydraulic power pack. Options include electric, diesel, or gasoline-powered units, each offering distinct advantages. Electric power packs are typically quieter and more environment-friendly, while diesel options may provide greater power in remote locations. Additionally, consider portability if the power pack will be frequently moved or used in various locations. Lastly, always review manufacturer specifications and seek out models with a reputation for reliability and support to ensure you are making a well-informed decision tailored to your operational needs.

Maintenance Best Practices for Extending the Lifespan of Hydraulic Power Packs

Regular maintenance is crucial for extending the lifespan of hydraulic power packs, as these systems are integral to the efficient operation of modern machinery. First and foremost, operators should establish a routine inspection schedule to check for leaks, wear, and damage to hydraulic hoses and connections. This proactive approach can identify potential issues before they escalate, reducing downtime and repair costs. Additionally, ensuring that the hydraulic fluid is clean and at the appropriate level is vital; contaminants can lead to serious component failure over time.

Furthermore, operators should focus on the lubrication of moving parts within the hydraulic system. Maintaining proper lubrication minimizes friction and heat generation, which can deteriorate performance and lead to premature failure. Monitoring operating temperatures is also essential; overheating can indicate an underlying issue that needs addressing. Lastly, consistent training for personnel on best operational practices will ensure that the hydraulic power packs are used within their designed parameters, contributing to their longevity and reliability in the dynamic environment of modern machinery.

Troubleshooting Common Issues with Hydraulic Power Packs in Modern Equipment

Hydraulic power packs are vital components in modern machinery, yet they can encounter various issues that impede their performance. One common problem is the loss of hydraulic fluid pressure, which can result from leaks in hoses or fittings. Regular inspection of these components is essential to identify any signs of wear or damage. Maintenance practices like ensuring proper hose routing and tightening connections can play a crucial role in preventing such issues, ultimately ensuring the smooth operation of equipment.

Another frequent issue involves overheating, which can lead to decreased efficiency and potential damage to the hydraulic system. Overheating typically occurs due to excessive operation or insufficient cooling. To troubleshoot this problem, operators should monitor the fluid temperature and ensure that the cooling system is functioning properly. Regular fluid changes and maintaining the correct fluid levels are also critical in preventing overheating and promoting optimal performance of hydraulic power packs in machinery.

Understanding the Essential Role of Hydraulic Power Packs in Modern Machinery - Troubleshooting Common Issues with Hydraulic Power Packs in Modern Equipment

| Issue | Symptoms | Possible Causes | Solutions |

|---|---|---|---|

| Low Pressure | Inadequate lifting or movement | Fluid leaks, air in system | Check for leaks, bleed air |

| Overheating | Unusual temperature rise | Low fluid levels, inefficient cooling | Refill fluid, improve ventilation |

| Unresponsive Controls | Functions do not engage | Faulty solenoid, electrical issues | Inspect wiring, replace solenoid |

| Excessive Noise | Loud or unusual sounds | Cavitation, worn components | Inspect for cavitation, replace parts |

| Fluid Contamination | Dark or murky fluid | Debris or old fluid | Change fluid, clean filters |

Related Posts

-

Unlocking Efficiency with Hydraulic Power Packs Understanding Their Impact on Industrial Applications

-

5 Essential Tips for Choosing the Right Hydraulic Pump Motor for Your Industrial Needs

-

7 Best Hydraulic Motors for Efficient Energy Solutions in 2024

-

Unveiling Hydraulic Parts Innovations at the 138th Canton Fair 2025 in China

-

Unlocking the Future of Machinery: Innovative Trends in Hydraulic Parts for Enhanced Efficiency

-

10 Best Hydraulic Cylinder Parts You Should Know

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us