The Ultimate Guide to Understanding Hydraulic Pumps and Motors for Efficient Machinery Performance

Hydraulic pumps and motors play a critical role in the efficiency and performance of modern machinery across various industries. According to the Fluid Power Journal, the global hydraulic market is projected to reach $47.1 billion by 2027, driven by advancements in productive equipment and an increasing need for automation. A well-optimized hydraulic system can enhance machinery reliability and reduce operational costs, making it essential for engineers and operators to fully understand the intricacies of hydraulic pumps and motors.

Hydraulic pumps and motors play a critical role in the efficiency and performance of modern machinery across various industries. According to the Fluid Power Journal, the global hydraulic market is projected to reach $47.1 billion by 2027, driven by advancements in productive equipment and an increasing need for automation. A well-optimized hydraulic system can enhance machinery reliability and reduce operational costs, making it essential for engineers and operators to fully understand the intricacies of hydraulic pumps and motors.

Understanding the specific applications, types, and maintenance needs of these components is vital, as improper use or lack of knowledge can lead to system failures and inefficiencies. This guide aims to provide comprehensive insights into hydraulic pumps and motors, empowering professionals to achieve optimal machinery performance while adapting to the fast-evolving landscape of fluid power technology.

Understanding the Basics: What Are Hydraulic Pumps and Motors?

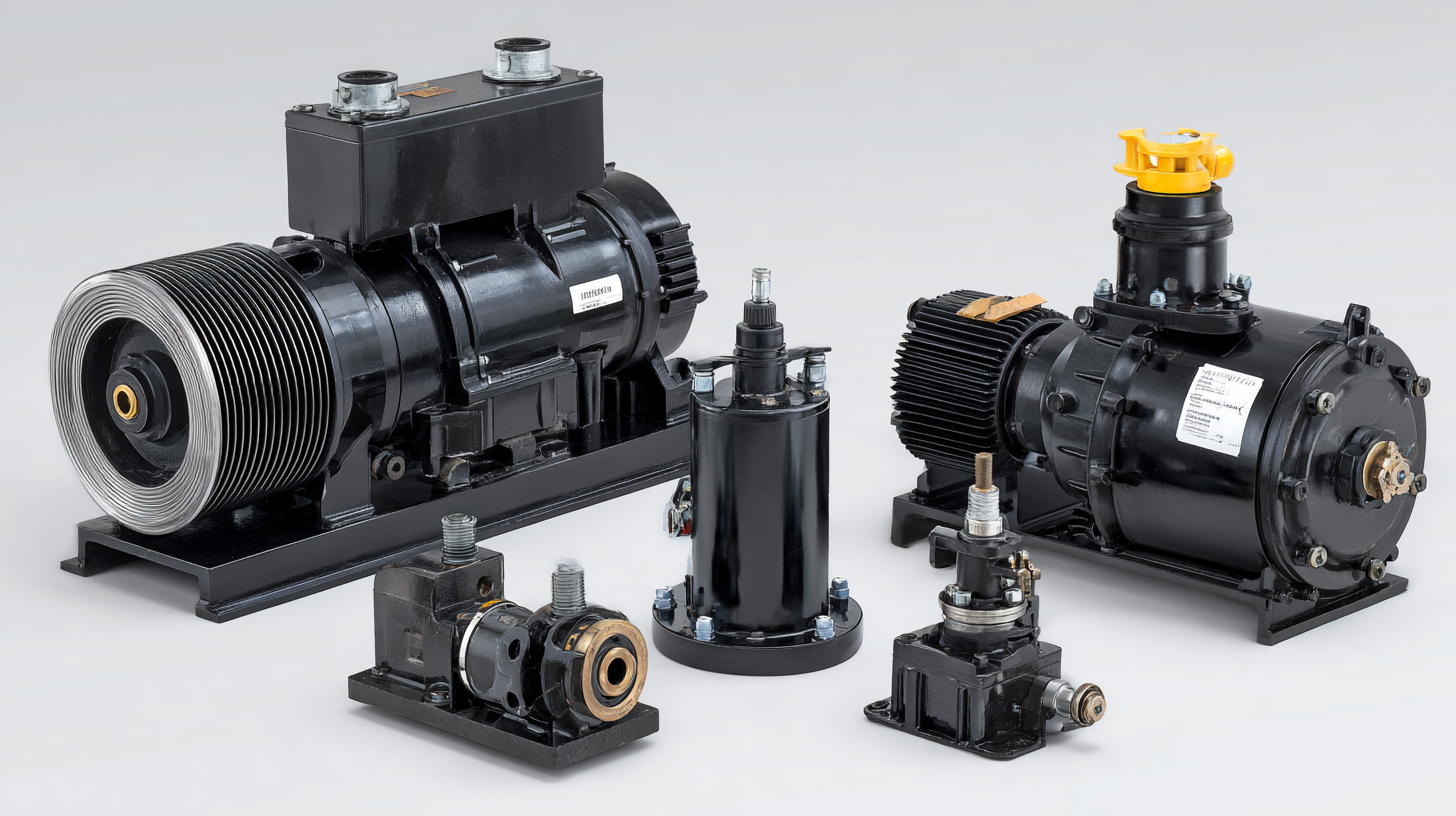

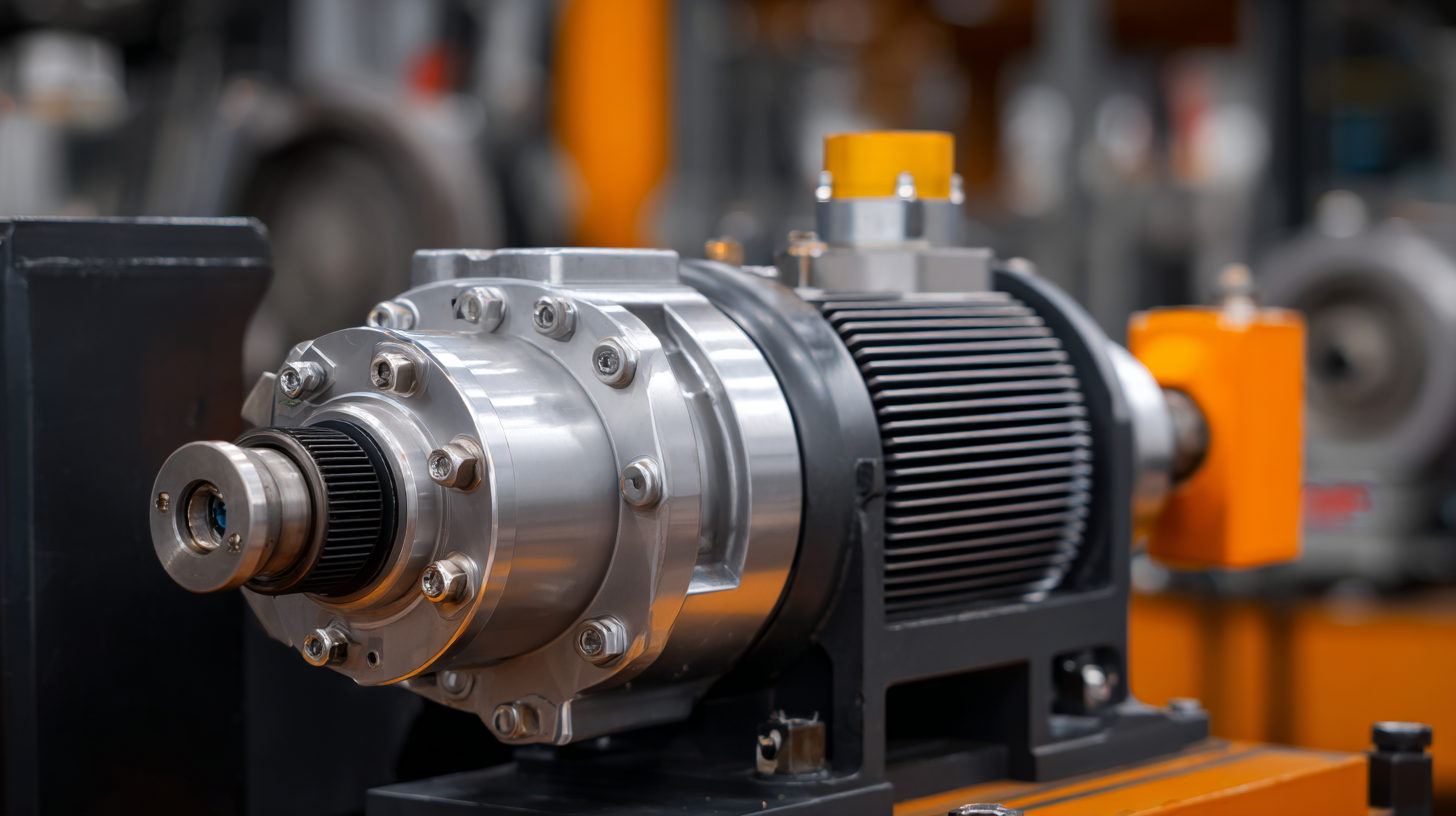

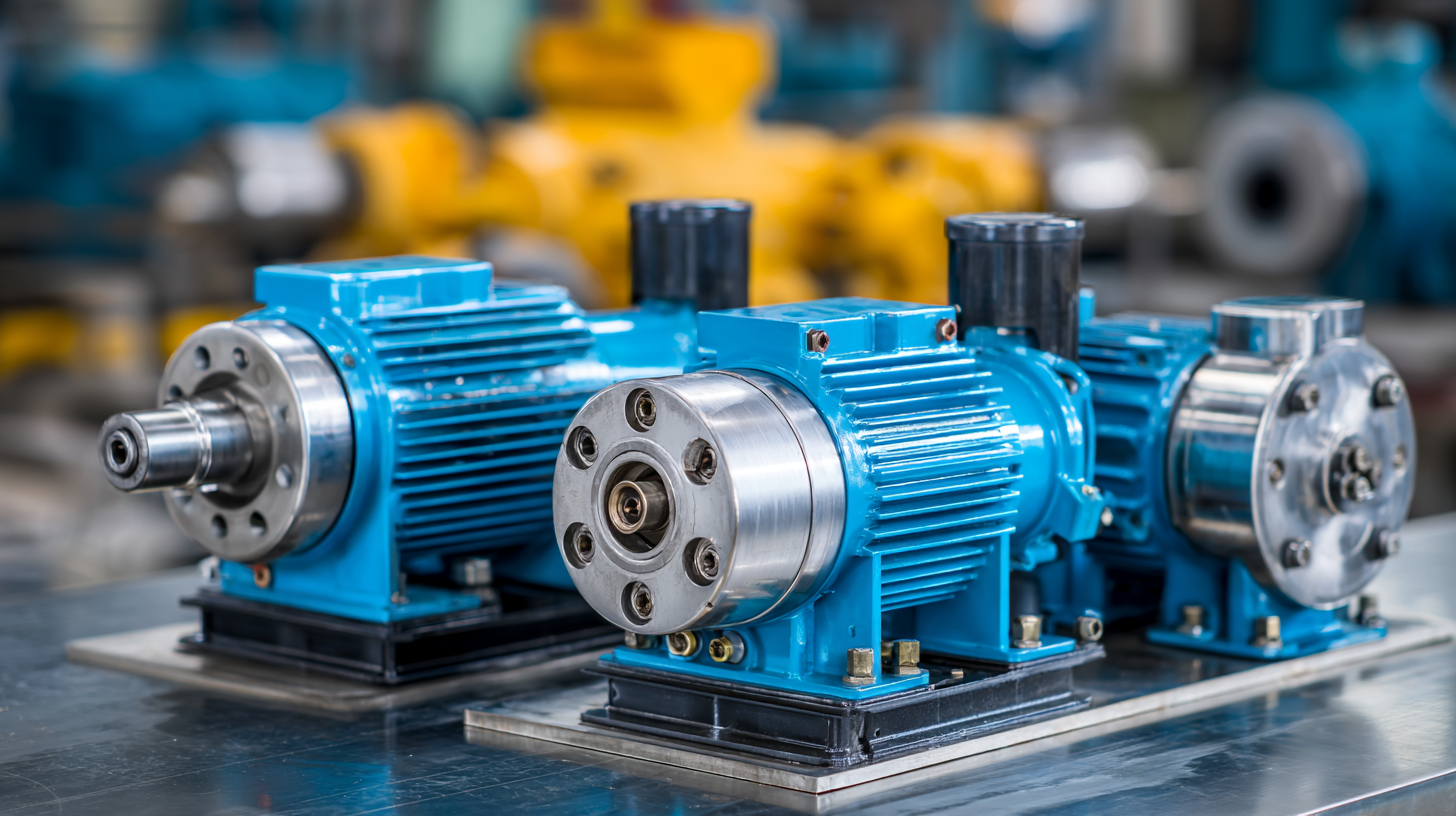

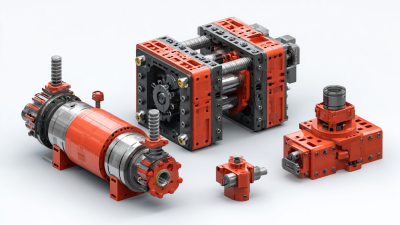

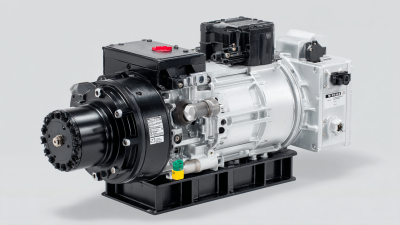

Hydraulic pumps and motors are critical components in hydraulic systems, converting mechanical energy into hydraulic energy and vice versa. At their core, hydraulic pumps function by drawing fluid from a reservoir and pressurizing it, which then powers various machinery and equipment. This process enables a wide range of applications, from construction machinery to automotive systems, where precise control and strong force are essential.

Hydraulic motors, on the other hand, translate hydraulic energy back into mechanical energy. When pressurized hydraulic fluid enters the motor, it causes rotor movement, producing torque and rotation. This mechanism allows machinery to perform tasks that require high levels of power and efficiency while maintaining compact designs. Understanding how these fundamental components work together is vital for optimizing machinery performance and ensuring operational efficiency across various industries.

The Ultimate Guide to Understanding Hydraulic Pumps and Motors for Efficient Machinery Performance

| Component Type | Function | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Hydraulic Pump | Converts mechanical energy into hydraulic energy | Construction machinery, agriculture equipment, industrial machinery | High efficiency, compact design, adjustable flow rate | Potential for fluid leaks, requires regular maintenance |

| Hydraulic Motor | Converts hydraulic energy into mechanical energy | Conveyor systems, automotive applications, marine equipment | High torque at low speeds, strong overload protection | Complexity in design, may suffer from low efficiency at high speeds |

| Gear Pump | Positive displacement pump that uses gears to pump fluid | Hydraulic systems, lubrication systems, fuel pumps | Simple design, high reliability, low cost | Limited pressure capability, produces pulsation |

| Vane Pump | Uses a series of vanes to pump fluid | Industrial fluid systems, hydraulic lifts, pilot controls | Smooth flow, good efficiency, low noise | More sensitive to contamination, limited operational environment |

| Piston Pump | Uses pistons to create pressure and flow | High-pressure applications, manufacturing, mining | Handles high pressure, versatile flow rates | More complex design, higher cost |

Key Components of Hydraulic Systems: Exploring the Functionality of Pumps and Motors

Hydraulic systems are integral to the functionality and efficiency of various industrial applications, primarily due to the critical roles played by hydraulic pumps and motors. Hydraulic pumps convert mechanical energy into hydraulic energy, generating the flow of hydraulic fluid throughout the system. This flow is essential for operating hydraulic motors, which then convert the hydraulic energy back into mechanical energy to perform work. According to a recent report by the International Society for Automation, about 45% of manufacturing machinery employs hydraulic systems, emphasizing the significance of understanding these components for optimal machinery performance.

The efficiency of hydraulic pumps and motors is pivotal, as it directly impacts the overall energy consumption of machinery. A study conducted by the Hydraulic Institute indicates that poorly maintained hydraulic systems can result in energy losses of up to 30%, which not only affects performance but also increases operational costs. By focusing on the key components, organizations can enhance the reliability of their machines. For instance, selecting variable displacement pumps, which adjust flow and pressure based on demand, can lead to significant energy savings—up to 20%—compared to fixed displacement pumps. This highlights the importance of understanding pump and motor functionalities to optimize hydraulic systems for both efficiency and cost-effectiveness.

Efficiency Metrics: Analyzing Performance Data for Hydraulic Machinery

The efficiency metrics of hydraulic pumps and motors and motors are crucial for evaluating the performance of hydraulic machinery. According to a 2022 report by the International Hydraulic Association, optimal efficiency in hydraulic systems can lead to energy savings of up to 30%. This efficiency is often measured using the volumetric, mechanical, and overall efficiency metrics that allow engineers to analyze how well the system converts input energy into effective work. For instance, while volumetric efficiency deals with the actual fluid moved versus the theoretical capacity, mechanical efficiency considers the losses due to friction and wear within the machinery.

Furthermore, advanced data analytics tools have become essential in interpreting performance data. A recent study published in the Journal of Hydraulic Engineering revealed that tracking performance metrics in real-time can enhance overall system efficiency by an additional 15%. With such technology, operators can easily identify any deviations from optimal performance, allowing for timely interventions that reduce downtime and maintenance costs. This level of analysis not only optimizes the use of resources but also extends the lifespan of hydraulic components, signifying the importance of leveraging performance data in increasingly competitive industrial environments.

Common Applications: Where Hydraulic Pumps and Motors Shine in Industry

Hydraulic pumps and motors play a crucial role in various industrial applications, showcasing their efficiency and reliability across multiple sectors. According to a recent report from MarketsandMarkets, the global hydraulic pumps market is projected to reach USD 29.4 billion by 2025, driven by increasing automation and the demand for high-performance machinery. In construction, hydraulic systems power heavy equipment such as excavators and cranes, providing the necessary force for lifting and digging operations. This reliance on hydraulic technology is evident, considering that hydraulic machinery accounts for over 40% of total equipment costs in the construction industry.

Another prominent sector where hydraulic pumps and motors excel is the manufacturing industry, particularly in material handling and production processes. The International Fluid Power Society states that hydraulic systems offer a force-to-weight ratio that is unmatched by electric alternatives, making them favorable for tasks requiring high torque at low speeds. Additionally, the versatility of hydraulic pumps allows for precise control, enhancing automation in assembly lines. With this robust performance, sectors such as automotive and aerospace are increasingly adopting hydraulic solutions, driving innovation and efficiency in their operations.

The Ultimate Guide to Understanding Hydraulic Pumps and Motors

This chart illustrates the common applications of hydraulic pumps and motors across various industries, highlighting their efficiency and performance benefits.

Maintenance Practices: Ensuring Longevity and Reliability of Hydraulic Equipment

Effective maintenance practices are crucial for ensuring the longevity and reliability of hydraulic equipment. Adopting a proactive maintenance strategy based on reliability analysis and Failure Mode and Effects Analysis (FMEA) can significantly enhance the performance of hydraulic systems. By identifying potential failure points and prioritizing maintenance activities accordingly, operators can minimize downtime and reduce costs associated with unexpected equipment failures.

Specific case studies, such as those focusing on hydraulic cylinders in excavators equipped with energy regeneration and recovery systems, illustrate the effectiveness of implementing tailored maintenance strategies. These approaches not only improve the operational efficiency of machinery but also extend the life of hydraulic components.

Proper lubrication and conditioning of hydraulic fluids play a vital role in protecting these systems, making the selection of high-quality hydraulic oils essential for optimal performance.

Related Posts

-

How to Choose the Right Hydraulic Pumps and Motors for Your Industrial Needs

-

Unveiling Hydraulic Parts Innovations at the 138th Canton Fair 2025 in China

-

Unlocking the Future of Machinery: Innovative Trends in Hydraulic Parts for Enhanced Efficiency

-

How to Optimize Air Hydraulic Pump Performance for Maximum Efficiency

-

Top Strategies for Optimizing Hydraulic System Efficiency

-

7 Best Hydraulic Motors for Efficient Energy Solutions in 2024

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us