Why Understanding Pneumatic and Hydraulic Systems is Essential for Modern Industries

In today’s rapidly evolving industrial landscape, the significance of understanding pneumatic and hydraulic systems cannot be overstated. According to a report by MarketsandMarkets, the global hydraulics market is projected to reach $53.3 billion by 2025, driven by the expanding demand for automation and efficiency in manufacturing processes. Similarly, the pneumatic systems market is expected to witness substantial growth, propelled by advancements in technology and the need for precise control in applications ranging from robotics to automotive assembly lines. Mastery of these systems equips professionals with the key insights to optimize machinery performance, improve safety measures, and enhance operational efficiency. As modern industries continue to embrace mechanization and innovation, a comprehensive understanding of pneumatic and hydraulic principles has become essential for engineers and technicians alike, ensuring they remain competitive in the workforce of the future.

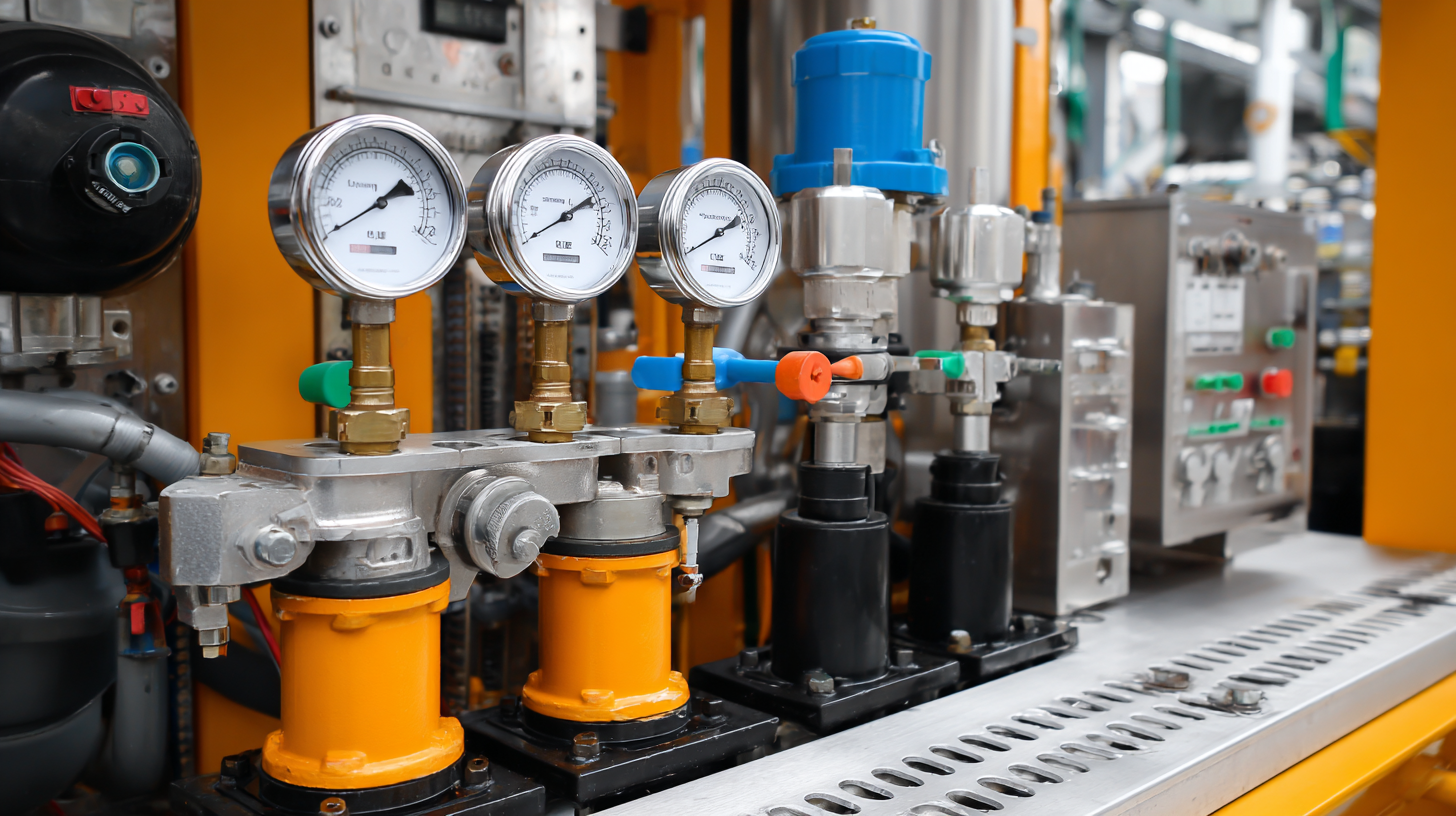

The Role of Pneumatic Systems in Enhancing Automation Efficiency

Pneumatic systems play a crucial role in enhancing automation efficiency across various modern industries. By utilizing compressed air to transmit power, these systems offer a lightweight, versatile solution for tasks that require speed and precision. Unlike hydraulic systems, which use fluids and can be heavy and slower to react, pneumatic systems excel in scenarios where rapid movement is essential, such as in assembly lines and robotic applications. Their quick response times and the ability to easily control pressure make them ideal for repetitive tasks, contributing to overall productivity.

**Tips:** When implementing pneumatic systems, ensure that your air compressors and filters are of high quality to prevent contamination. Regular maintenance checks can significantly enhance system longevity and efficiency, preventing unexpected downtime.

Moreover, the integration of smart technology into pneumatic systems is further transforming automation. With advanced sensors and IoT connectivity, industries can monitor performance in real time, optimize air consumption, and reduce waste. This not only leads to more sustainable operations but also allows for predictive maintenance, which can save costs and improve operational efficiency.

**Tips:** Investing in training for your workforce on the specifics of pneumatic systems can maximize the benefits. Understanding the system's capabilities can lead to innovative applications that improve both speed and safety in the workplace.

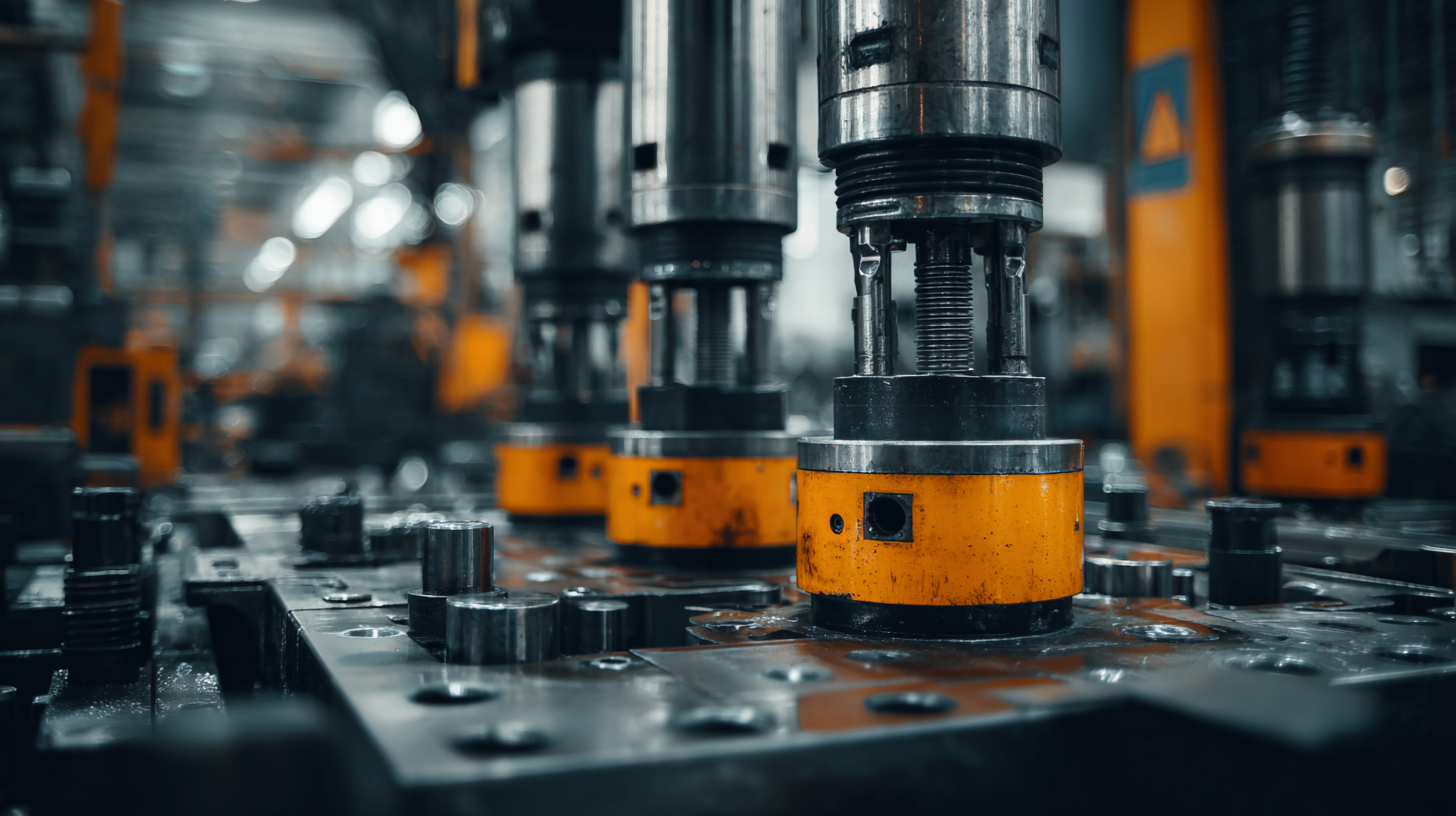

Key Advantages of Hydraulic Systems in Heavy Machinery Operations

Hydraulic systems play a pivotal role in the operation of heavy machinery, offering distinct advantages that significantly enhance performance and efficiency. One of the primary benefits of hydraulic systems is their ability to generate large amounts of force with relatively small inputs. This allows heavy machinery, such as excavators and loaders, to perform powerful tasks like digging, lifting, and moving heavy materials with precision and control. The efficiency of hydraulic systems stems from their use of incompressible fluids, which transmit force effectively, minimizing energy loss during operation.

Moreover, hydraulic systems provide greater operational flexibility compared to their pneumatic counterparts. With the capability to maintain consistent pressure regardless of load changes, hydraulic systems ensure that heavy equipment can function smoothly under various conditions. This adaptability is crucial in industries such as construction and manufacturing, where tasks often require different levels of force and precision. As a result, hydraulic-powered machines not only accomplish demanding tasks but also enhance safety and productivity, making them essential tools in modern industrial operations.

Why Understanding Pneumatic and Hydraulic Systems is Essential for Modern Industries

| Dimension | Pneumatic Systems | Hydraulic Systems |

|---|---|---|

| Power Density | Low | High |

| Efficiency | 70-80% | 80-90% |

| Operating Pressure | 6-8 bar | 70-700 bar |

| Control Precision | Moderate | High |

| Common Applications | Packaging, Material Handling | Construction, Manufacturing |

| Maintenance | Less frequent | More frequent |

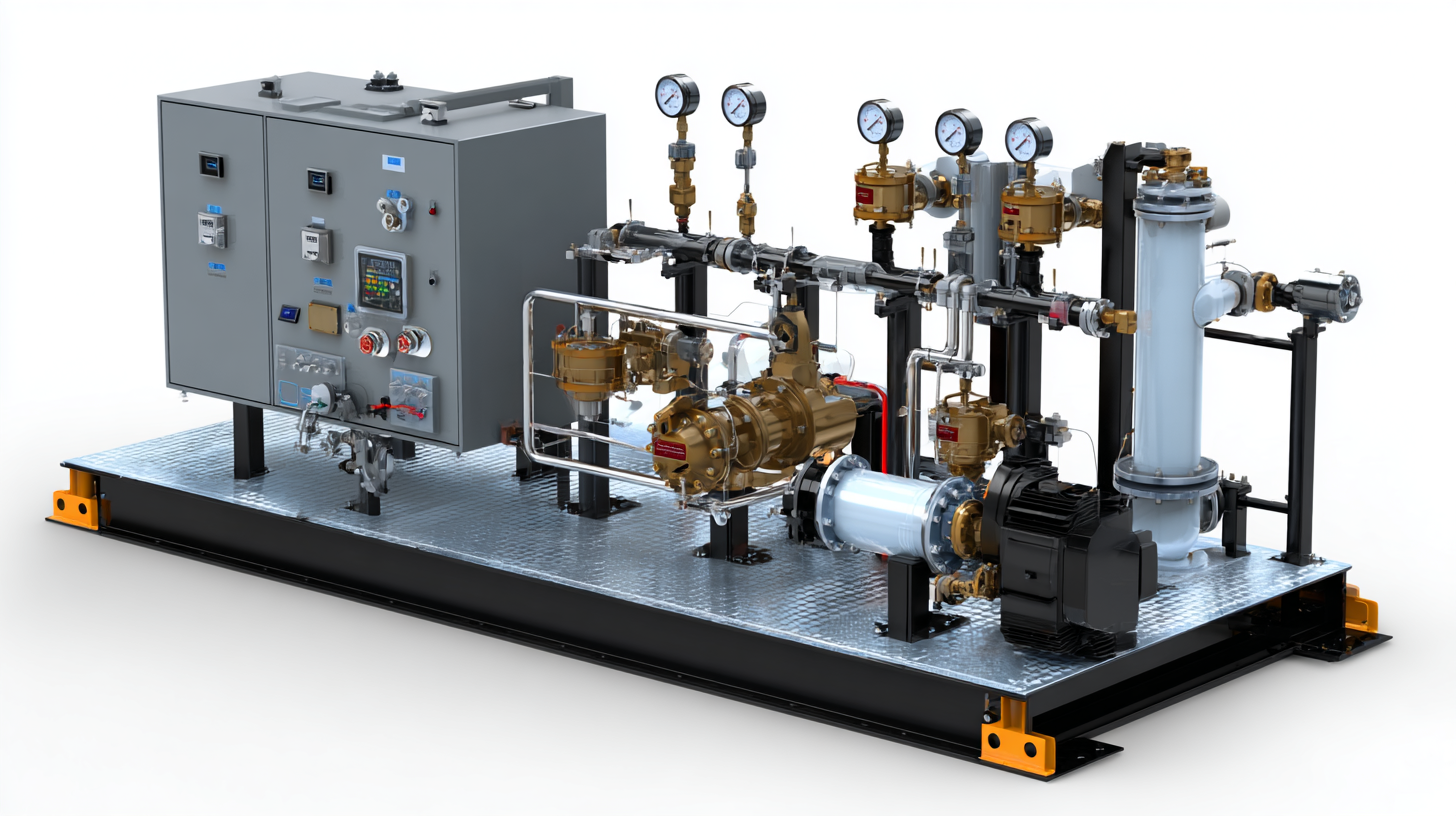

Integrating Pneumatic and Hydraulic Technologies for Optimal Performance

Integrating pneumatic and hydraulic technologies plays a crucial role in enhancing the performance and efficiency of modern industrial systems. Both systems utilize fluids to transmit power, but they serve different functions and applications. Pneumatic systems are typically used for lighter tasks that require quick movements, while hydraulic systems are employed for more demanding applications, offering higher force output. By merging these two technologies, industries can capitalize on their complementary strengths, resulting in improved productivity and reduced operational costs.

The optimal integration of pneumatic and hydraulic systems can lead to significant advancements in manufacturing processes. For instance, a manufacturing line could use pneumatic actuators for rapid positioning while relying on hydraulic presses for heavy lifting and forming tasks. This hybrid approach not only maximizes efficiency but also enhances control and precision in operations. Additionally, it allows for greater flexibility in machinery design, enabling manufacturers to tailor their systems to meet specific operational needs. As industries increasingly rely on sophisticated automation, understanding and integrating these technologies is essential for staying competitive in today’s fast-paced market.

Future Trends in Pneumatic and Hydraulic System Innovations

The future of pneumatic and hydraulic system innovations is poised for significant advancements driven by emerging technologies and industry demands. One of the most exciting trends is the integration of smart technology into these systems. By incorporating sensors and IoT devices, companies can enhance the efficiency and reliability of pneumatic and hydraulic systems. Real-time data collection will enable predictive maintenance, minimizing downtime and improving overall operational efficiency.

Moreover, the push for sustainability is leading to the development of eco-friendly hydraulic fluids and energy-efficient pneumatic components. Manufacturers are focusing on reducing their carbon footprint by creating systems that consume less energy and produce lower emissions. The exploration of alternative materials and renewable resources will not only enhance system performance but also address environmental concerns. As industries strive for greener operations, these innovations will play a crucial role in shaping the future of pneumatic and hydraulic systems.

Trends in Pneumatic and Hydraulic System Innovations

Impact of Training and Knowledge on Managing Pneumatic and Hydraulic Systems

Training and knowledge play a crucial role in effectively managing pneumatic and hydraulic systems within modern industries. These systems are fundamental for achieving high efficiency and reliability in operations, but their complexity requires a workforce that is well-versed in their mechanics and applications. Proper training equips employees with the skills necessary to troubleshoot and maintain these systems, reducing the likelihood of malfunctions that can lead to costly downtimes or safety hazards.

Moreover, the advancement of technology in pneumatic and hydraulic systems necessitates continuous education and specialization. As industries evolve, professionals must stay updated with the latest techniques, tools, and protocols to optimize system performance. Educational programs and workshops focused on these systems foster a deeper understanding, enabling engineers and operators to implement innovative solutions, enhance productivity, and ensure compliance with safety regulations. Therefore, investment in training not only enhances individual competence but also contributes significantly to the overall success of the organization.

Related Posts

-

10 Essential Tips for Mastering Pneumatic and Hydraulic Systems

-

Essential Pneumatic Hydraulic Maintenance Checklist for Optimal Performance

-

Pneumatic Hydraulics Versus Traditional Hydraulics A Comprehensive Comparison of Efficiency and Performance

-

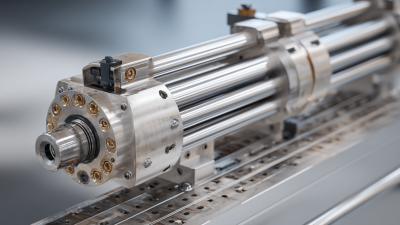

Understanding the Key Components of Hydraulic Cylinder Parts

-

10 Best Hydraulic Cylinder Parts You Should Know

-

How to Optimize Pneumatic Hydraulic Systems for Enhanced Performance

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us