Unlocking Efficiency with Hydraulic Power Packs Understanding Their Impact on Industrial Applications

In today's industrial landscape, efficiency and productivity are paramount, driving companies to seek innovative solutions to optimize operations.

Hydraulic power packs have emerged as critical components in this endeavor, providing reliable and powerful energy sources for various machinery and processes.

According to a report by Market Research Future, the global hydraulic power pack market is projected to reach USD 5 billion by 2023, growing at a CAGR of 4.5% due to increasing demand in sectors such as construction, manufacturing, and marine industries.

These compact power units enable effective operation of hydraulic systems, contributing to improved energy efficiency and reducing operational downtime.

As industries strive to enhance their performance, understanding the impact of hydraulic power packs on efficiency is crucial for future developments, enabling businesses to remain competitive in an ever-evolving market.

Hydraulic power packs have emerged as critical components in this endeavor, providing reliable and powerful energy sources for various machinery and processes.

According to a report by Market Research Future, the global hydraulic power pack market is projected to reach USD 5 billion by 2023, growing at a CAGR of 4.5% due to increasing demand in sectors such as construction, manufacturing, and marine industries.

These compact power units enable effective operation of hydraulic systems, contributing to improved energy efficiency and reducing operational downtime.

As industries strive to enhance their performance, understanding the impact of hydraulic power packs on efficiency is crucial for future developments, enabling businesses to remain competitive in an ever-evolving market.

Hydraulic Power Packs: A Comprehensive Overview of Their Functionality

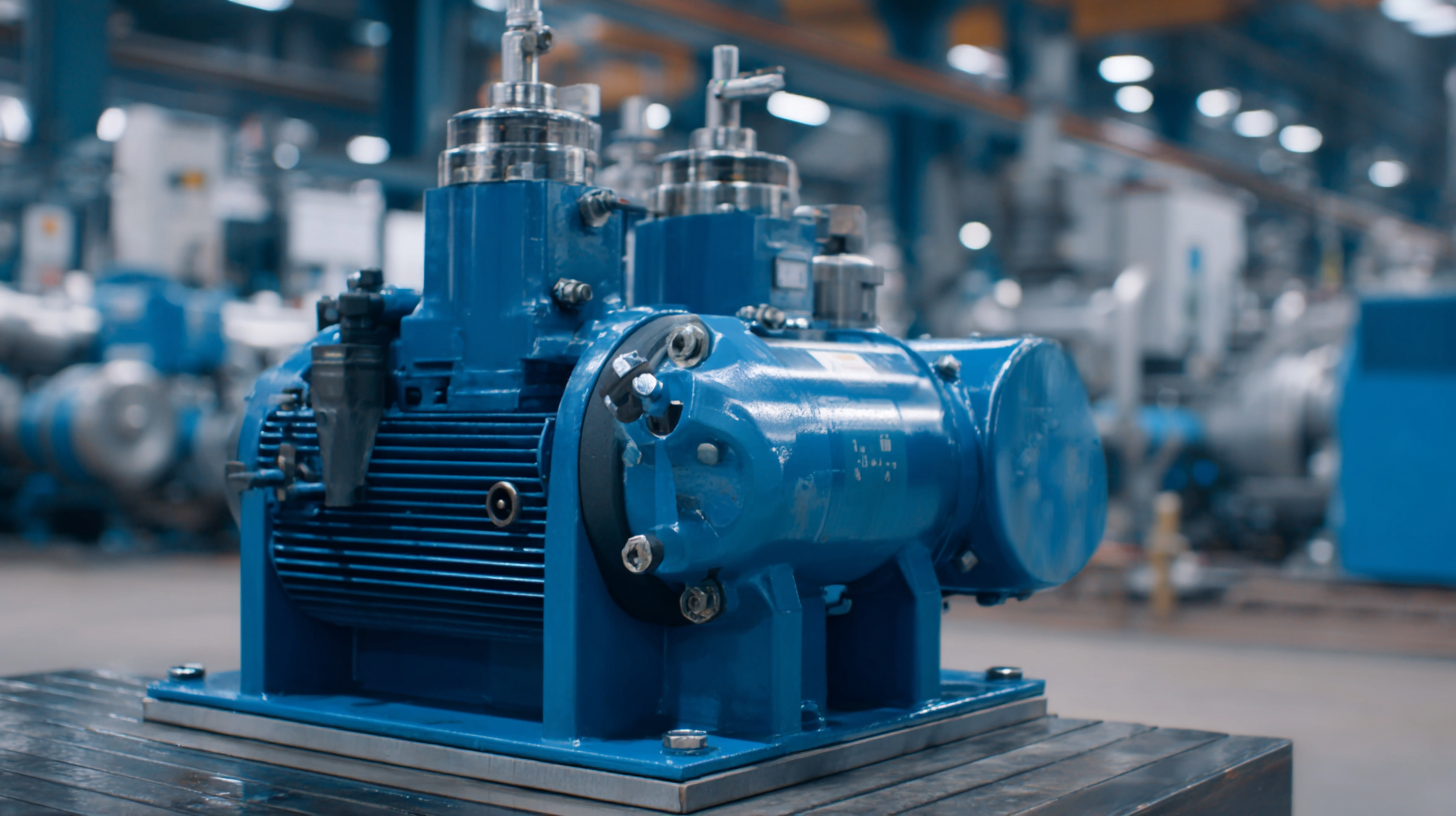

Hydraulic power packs are essential components in various industrial applications, providing a reliable source of power to hydraulic systems. These compact units are designed to convert mechanical energy into hydraulic energy, facilitating operations such as lifting, pressing, and conveying materials. The functionality of hydraulic power packs lies in their ability to generate high pressure while maintaining efficiency, making them ideal for tasks that require significant force in confined spaces.

The core functionality of a hydraulic power pack includes a motor, pump, reservoir, and control mechanisms. The motor drives the hydraulic pump, which generates pressurized fluid from the reservoir. This pressurized fluid is then directed through hoses and valves to perform work on hydraulic actuators such as cylinders and motors. The control systems enhance performance by allowing precise modulation of pressure and flow, ensuring that the machinery operates smoothly and effectively. By understanding the mechanics of hydraulic power packs, industries can optimize their processes, enhance productivity, and prolong the lifespan of their equipment.

Key Benefits of Integrating Hydraulic Power Packs in Industrial Operations

Hydraulic power packs represent a game-changing technology for industrial operations, offering significant benefits that enhance efficiency and productivity. One of the primary advantages of integrating hydraulic power packs is their ability to provide high power density. This means that they can generate substantial force in a compact design, allowing for powerful machinery to operate effectively in limited spaces. As a result, businesses can optimize their facilities without compromising performance, making the hydraulic power pack an essential component in many industrial settings.

Moreover, hydraulic power packs contribute to improved energy efficiency. By utilizing hydraulic systems to transmit power, these packs enable precise control over machinery, reducing energy waste during operation. The smooth modulation of forces can enhance the operational lifespan of equipment by minimizing wear and tear, which in turn lowers maintenance costs. As industrial sectors look to adopt more sustainable practices, the energy-efficient nature of hydraulic power packs becomes increasingly important, leading to both cost savings and a reduced environmental impact. This alignment with sustainability goals ensures that companies can leverage hydraulic technology not only for immediate benefits but also for long-term viability in an evolving industrial landscape.

Exploring Diverse Industrial Applications for Hydraulic Power Packs

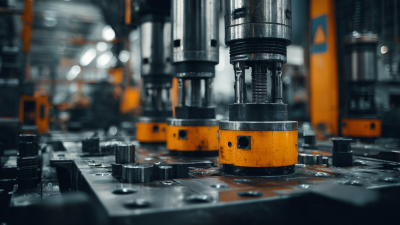

Hydraulic power packs are versatile systems that play a crucial role in various industrial applications. These power packs convert mechanical energy into hydraulic energy, delivering precise control and substantial force for tasks such as lifting, pressing, and moving heavy loads. Industries ranging from manufacturing and construction to aerospace and automotive continually benefit from their efficiency and reliability. For instance, in the construction sector, hydraulic power packs are essential for operating cranes and excavators, enabling smooth and powerful maneuverability to complete challenging tasks.

**Tips:** When selecting a hydraulic power pack for your application, consider the specific requirements such as flow rate, pressure, and compatibility with existing systems. Regular maintenance and inspections are also vital to ensure optimal performance and prolong the lifespan of the equipment.

In the automotive industry, hydraulic power packs are invaluable for assembly lines, where they power tools for fastening and bending components. Their quick response times and consistent output improve productivity, reducing downtime and enhancing overall operational efficiency. Additionally, with advancements in technology, modern hydraulic power packs are becoming more energy-efficient, offering sustainable solutions for heavy machinery needs.

**Tips:** Explore options for variable-speed hydraulic power packs to enhance energy efficiency further, and consider integrating smart technology for real-time monitoring to optimize performance and reduce energy consumption.

Unlocking Efficiency with Hydraulic Power Packs Understanding Their Impact on Industrial Applications

| Application Area | Benefits of Hydraulic Power Packs | Typical Operating Pressure (bar) | Efficiency Improvement (% Increase) | Common Equipment |

|---|---|---|---|---|

| Automotive Manufacturing | Increased speed of assembly lines | 200 | 15% | Robotic arms, presses |

| Construction | Improved lifting and moving capabilities | 250 | 20% | Excavators, crane systems |

| Agriculture | Enhanced operational efficiency | 180 | 10% | Tractors, plows |

| Mining | Higher power output for heavy machinery | 300 | 25% | Loaders, drill rigs |

| Manufacturing | Precision control in industrial processes | 220 | 18% | CNC machines, hydraulic presses |

Innovations and Trends Shaping the Future of Hydraulic Power Technology

The evolution of hydraulic power technology is marked by remarkable innovations that significantly enhance efficiency and productivity across various industrial applications. One of the most notable trends is the integration of smart technology into hydraulic power packs. By incorporating IoT connectivity, these systems can now offer real-time monitoring and analytics, allowing operators to optimize performance, predict maintenance needs, and reduce downtime. This shift not only streamlines operations but also contributes to sustainable practices by minimizing energy consumption.

Furthermore, advancements in design and materials are shaping the future of hydraulic systems. Lightweight, durable materials are being utilized to manufacture hydraulic power packs that are both efficient and easy to install. Additionally, the development of compact designs allows for versatile applications, enabling industries to save space without compromising on power. As research progresses, the focus on automation and robotics within hydraulic solutions promises to revolutionize workflows, driving productivity levels to unprecedented heights while maintaining reliability and safety in industrial settings.

Hydraulic Power Packs in Industrial Applications

This chart illustrates the efficiency improvements achieved through the adoption of hydraulic power packs across various industrial sectors over the last decade.

Best Practices for Maintenance and Troubleshooting of Hydraulic Power Packs

Proper maintenance and troubleshooting of hydraulic power packs are essential to ensure their optimal performance and longevity in industrial applications. According to a report by the International Journal of Engineering Research, regular maintenance can extend the lifespan of hydraulic systems by up to 30%. Key maintenance practices include checking for leaks, regularly replacing filters, and ensuring fluid levels are appropriate. Ignoring these factors can lead to a significant drop in efficiency, causing downtime that could cost organizations thousands of dollars per hour.

Tips: Always conduct a thorough inspection of the hydraulic fluid for contamination before starting any maintenance work. Using a filtration system can help prevent the entry of dirt and particulates, ensuring the hydraulic fluid remains clean and efficient.

Additionally, troubleshooting issues promptly is critical. The Hydraulic Institute recommends maintaining a log of performance metrics to identify trends that could indicate underlying issues. For instance, a sudden drop in pressure readings may suggest blockages or component wear that requires immediate attention to prevent catastrophic failures.

Tips: When troubleshooting, use diagnostic tools such as pressure gauges and flow meters, which can provide valuable insights into system health, helping to pinpoint the root cause of any issues quickly.

Related Posts

-

How to Optimize the Performance of Your Hydraulic Pump Motor

-

Innovative Solutions for Fluid Power Hydraulics Efficiency

-

10 Essential Tips for Mastering Pneumatic and Hydraulic Systems

-

Exploring the Versatile Applications of Hydraulic Gear Pumps in Various Industries

-

Understanding the Key Components of Hydraulic Cylinder Parts

-

Why Understanding Pneumatic and Hydraulic Systems is Essential for Modern Industries

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us